3.

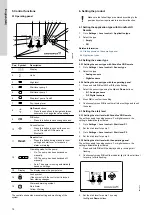

Depending on the type of wire, take one of the following

actions:

• For a shielded wire, lead it through the cable clamp.

CIO1

GND

TM070571

• For a not shielded wire, attach it to the protection cover with

a cable tie.

DIO1 GND DIO2 GND DI1

GND DI2

GND

CIO1 GND CIO2 GND 24V

GND 24V

GND

TM070760

4.

Depending on the type and function of the sensor, connect the

wires to the following terminals. When using an analog sensor,

level switches can be used to add redundance or security by

adding an extra dry-run sensor or high-level sensor or both.

Sensor type

Sensor function

Terminals

Analog

All levels

CIO1 - GND - 24 V

Digital

Dry-running level

CIO2 - GND

Stop level

DIO1 - GND

Start level, pump 1

DIO2 - GND

Start level, pump 2

DI1 - GND

High level

DI2 - GND

Related information

2.2.2 Removing the front cover

3.6 Configuring the IO terminals using Grundfos GO Remote

2.3.5 Connecting an alarm device

You can connect an alarm device, such as a buzzer or a lamp, to

the output relays

Alarm 1

and

Alarm 2

. The control unit triggers the

alarm device when it detects an alarm or a warning. You can

change the behaviour of the outputs with Grundfos GO Remote

under

Relay output 1

and

Relay output 2

.

You can also set the alarm device to be activated during normal

operation. It will only be deactivated in case of an alarm, a warning,

or mains failure. The setting is made in Grundfos GO Remote.

Go to

Settings

>

LC 231 IO terminals

>

Relay output

>

Function

.

Default settings of the terminal blocks

Terminal block

Default function

Alarm 1

All alarms

Alarm 2

High level

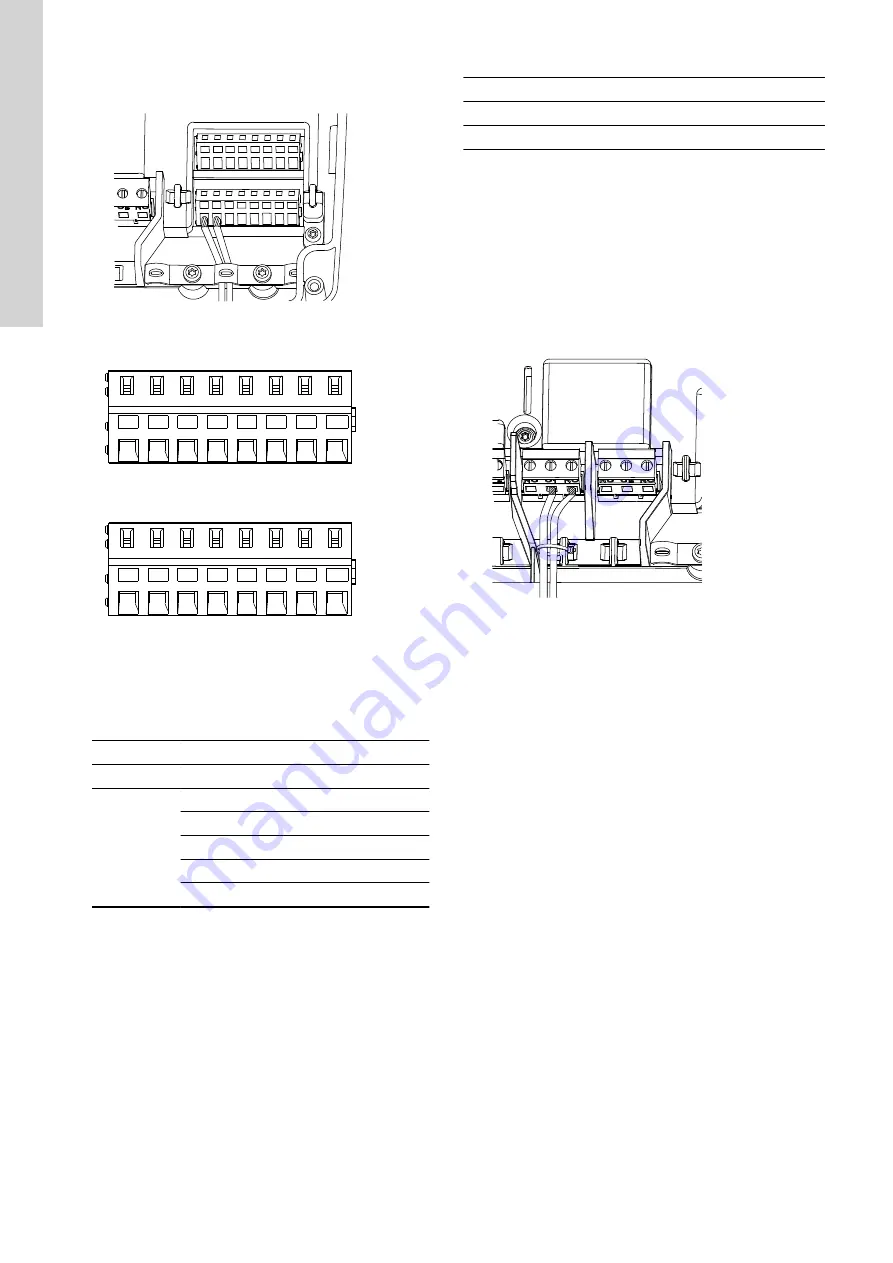

1.

Loosen the screws and remove the front cover.

Be careful not to damage the cable between the front cover

and the back cover.

2.

Lead the wires through one of the cable glands.

3.

Depending on the type of alarm device, connect the wires to

the relevant terminals. Note that all wires must be secured

inside the cabinet using cable ties.

•

NO

(Normally Open) and

C

(Common)

•

NC

(Normally Closed) and

C

(Common).

4.

Tie the wires with cable ties.

NC

NC N NO

TM070569

3. Starting up the product

3.1 Connecting to Grundfos GO Remote

Before connecting the product to Grundfos GO Remote, the

Grundfos GO Remote app must be downloaded to your smartphone

or tablet. The app is free of charge and available for iOS and

Android devices.

1.

Open Grundfos GO Remote on your device. Make sure that

Bluetooth is enabled.

Your device must be within reach of the product to establish

Bluetooth connection.

2.

Press the Bluetooth

CONNECT

button on Grundfos GO

Remote.

3.

Press the connect button on the operating panel. The blue LED

above the connect button is flashing until your device is

connected. Once the connection is established, the LED will be

permanently on.

Grundfos GO Remote is now loading the data for the product.

Related information

3.4 How to enable Bluetooth on the operating panel

3.5 How to disable Bluetooth on the operating panel

3.2 Startup wizard on Grundfos GO Remote

The product is designed for Bluetooth communication with Grundfos

GO Remote.

Once you have connected your product to Grundfos GO Remote, a

startup wizard appears. Follow the instructions to make your

settings.

Grundfos GO Remote enables you to set functions and gives you

access to status overviews, technical product information and

current operating parameters.

10

English (GB)

Summary of Contents for LC 231

Page 2: ......