•

operating indication, such as power on and pump running

•

alarm and warning indication, such as power phase missing

and high-water level

•

motor and phase failure protection

•

setting of stop delays matching the actual operating conditions

•

automatic alternation of pumps.

4.4 Application types

You can choose between two application types:

•

Empty

•

Fill

.

You can set the application type with Grundfos GO Remote.

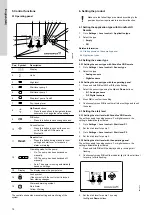

Empty

1

2

3

4

5

TM0713341

Pos.

Description

1

High level

2

Start level P2

: start level for pump 2

3

Start level P1

: start level for pump 1

4

Stop level

5

Dry-running level

The pump will start to empty the tank or pit when

Start level P1

is

reached.

A second pump will start if the liquid level reaches

Start level P2

.

The pump stops when the liquid level is lowered to

Stop level

.

If the inflow of liquid exceeds the capacity of the installed pump, the

level in the tank or pit will rise. Eventually, the

High level

sensor will

register a high liquid level in the tank or pit. If set, the signal from

the

High level

sensor can be used to activate an output relay which

can then be used to give a visual or acoustic alarm or send a signal

to a SCADA system.

If the pump is running and the liquid level in the tank or pit falls

below the dry-running level, the dry-running protection will stop the

pump to ensure that it is not damaged mechanically.

Fill

1

2

3

4

5

TM0713351

Designation

Description

1

High level

2

Stop level

3

Start level P1

: start level for pump 1

4

Start level P2

: start level for pump 2

5

Dry-running level

In the filling application, the pump is installed in a tank or well from

where it pumps the liquid. The liquid is pumped into a second tank

where the level sensors are installed.

The pump will start to fill the second tank when

Start level P1

is

reached.

A second pump will start if the liquid level reaches

Start level P2

.

The pump stops when the liquid level reaches

Stop level

.

If the pump for some reason does not stop at

Stop level

and the

liquid level keeps rising, the

High level

sensor will eventually

register this. If set, the signal from the

High level

sensor can be

used to activate a relay output which can then be used to give a

visual or acoustic alarm or send a signal to a SCADA system via a

communication interface.

If the pump is running and the liquid level in the tank falls below the

dry-running level, the dry-running protection will stop the pump to

ensure that it is not damaged.

Related information

6.1 Setting the application type with Grundfos GO Remote

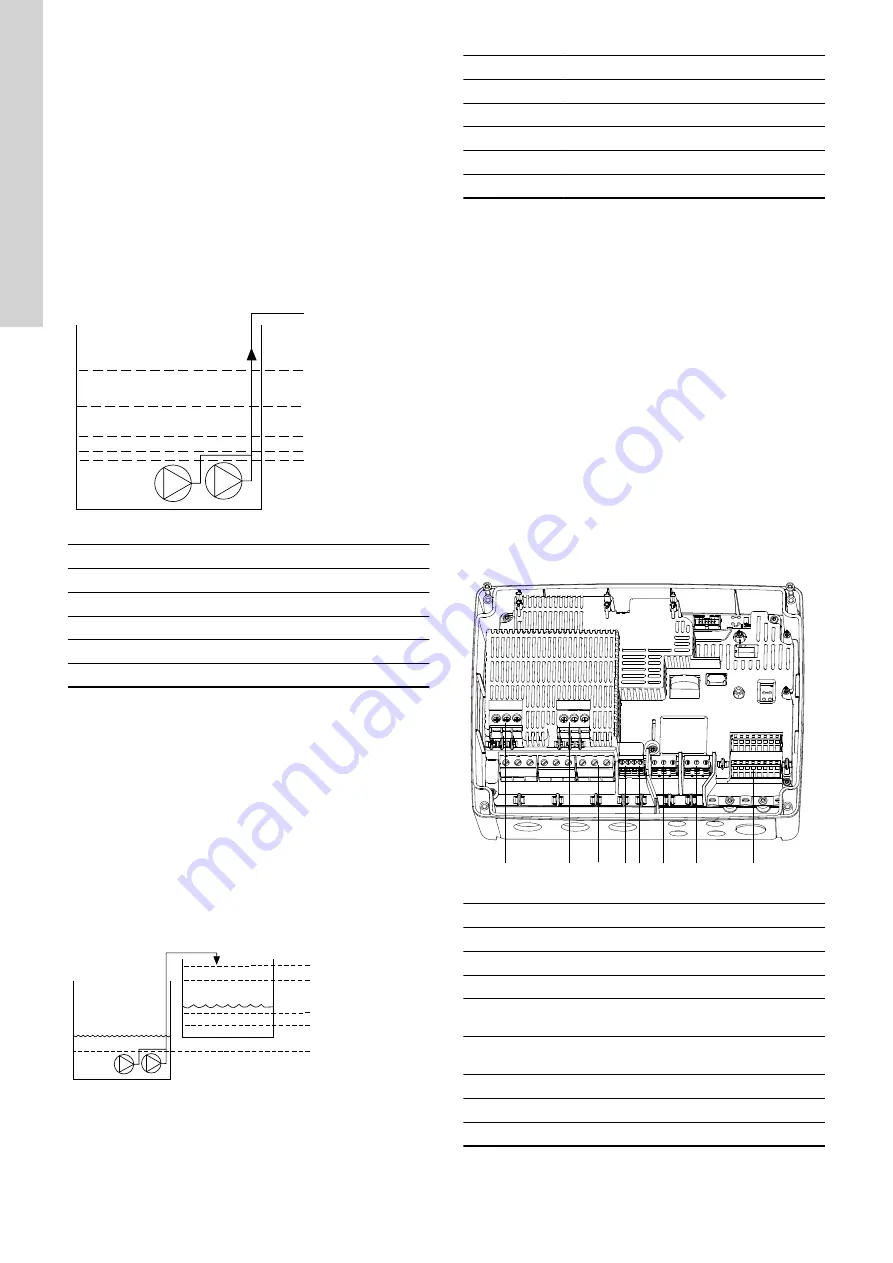

4.5 Terminals

1

2

3

6

4 5

7

8

TM070123

Pos. Description

1

Contactor for pump 1

2

Contactor for pump 2

3

Terminal block for the power supply

4

Terminal block for temperature and moisture-protection

sensor for pump 1

5

Terminal block for temperature and moisture-protection

sensor for pump 2

6

Alarm 1

7

Alarm 2

8

Analog and digital inputs and outputs.

12

English (GB)

Summary of Contents for LC 231

Page 2: ......