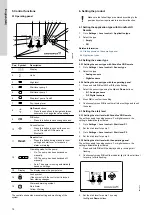

5. Control functions

5.1 Operating panel

7

6

8

8

9

11

10

13

14

15

12

5

4

3

2

1

TM070082

Pos. Symbol

Description

1

Display

2

ft

m

Units

3

High level

4

Start level, pump 2

5

Start level, pump 1

6

Stop level, pump 1 and 2

7

Dry-running level

8

Up

/

Down

buttons:

•

Press these buttons to navigate between

submenus or change the value settings.

9

OK

button:

•

Press this button to save changed values.

10

Connect button:

•

Press this button to connect the control

unit to Grundfos GO Remote via

Bluetooth.

11

Reset

button:

•

Press this button during startup to reset

settings and start over or to reset an

alarm or warning.

12

On Off Auto

Operating mode for the pump:

•

On: The pump has been switched on

manually.

•

Off: The pump has been switched off

manually.

•

Auto: The pump is running automatically

based on settings.

13

Display

The display shows the pump status.

14

Setpoint

5.00 bar

Operaring mode

Normal

Actual controlled value

4.90 bar

Control mode

Const. pressure

Status Settings Assist

1

2

3

5

6

7

8

9

Lock symbol:

If the symbol is lit, the control unit is locked

from making changes.

15

Alarm and warning symbol:

Red: Alarm

Yellow: Warning

The control unit enables manual setting and monitoring of the

system.

6. Setting the product

Make sure that all settings are entered according to the

pump and system requirements to avoid malfunction.

6.1 Setting the application type with Grundfos GO

Remote

1.

Go to

Settings

>

Level control

>

Application type

.

2.

Select the type.

•

Empty

•

Fill

Related information

3.3 Startup wizard on the operating panel

6.2 Setting the sensor type

6.2.1 Setting the sensor type with Grundfos GO Remote

1.

Go to

Settings

>

Level control

>

Sensor type

.

2.

Select the type.

•

Analog sensors

•

Digital sensors

6.2.2 Setting the sensor type with the operating panel

1.

Press and hold

OK

until

S-1

or

S-2

starts flashing.

2.

Select the sensor type using the

Up

and

Down

buttons.

•

S-1

:

Analog sensors

•

S-2

:

Digital sensors

.

3.

Press

OK

to confirm the setting.

4.

Continuously press

OK

to confirm all other settings and to exit

the setup.

6.3 Setting the start level

6.3.1 Setting the start level with Grundfos GO Remote

The settings apply to analog sensors. For digital sensors, the

setting is automatically activated.

1.

Go to

Settings

>

Level control

>

Start level P1

.

2.

Set the start level for pump 1.

3.

Go to

Settings

>

Level control

>

Start level P2

.

4.

Set the start level for pump 2.

6.3.2 Setting the start level with the operating panel

The settings apply to analog sensors. For digital sensors, the

setting is automatically activated.

1.

Press and hold

OK

until the display and dry running start

flashing.

2.

Continuously press

OK

until the indicator light for the start level

for pump 1 starts flashing.

TM071336

3.

Set the start level for pump 1 by using

the

Up

and

Down

buttons.

14

English (GB)

Summary of Contents for LC 231

Page 2: ......