Note that the curves are examples and cannot be used for

readings.

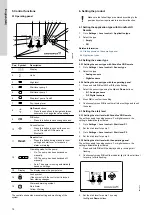

IEC trip curves

0.0

1

5

10

10

50

100

100

500

1000

1000

5000

10000

2

3

4

1

A

170

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

2.25

X

Y

TM072668

Pos.

Description

Y

Time [s]

X

x I

rated

A

Class "p"

1

Class 30

1

Class 20

3

Class 10

4

Class 5

Example:

1.

Set the IEC trip class to class 20.

2.

Set the overload limit to 10 A. The rated motor current is stated

on the nameplate.

At a motor current of 22.5 A (10 x 2.25), a pump is to cut out after

approx. 170 seconds. In addition to IEC trip curves, a fixed 4 x

I

rated

in 2 seconds is implemented to protect especially small motors

from overheating (see grey area on drawing).

Contactor Current Protection (CCP)

In addition to the IEC trip class, a Contactor Current Protection

(CCP) trip class is implemented to protect the internal contactors in

the product from overheating.

10000

1000

100

10

1

0.1

10

20

30

40

50

60

70

80

Y

5

4

3

2

6

X

1

TM072272

Pos.

Description

Y

Trip time [s]

X

Current [A]

1

CCP

2

Class 30

Pos.

Description

3

Class 20

4

Class 10

5

Class 5

6

CCP + Class 20

Full-load current is set to 10 [A] and trip class 20 is selected.

•

Motor overload. When the motor is overloaded with 15 [A], it

will take ~800 seconds to trip the motor protection when trip

class 20 is selected.

•

The pump is blocked. If the pump is blocked and the motor has

a locked-rotor current specified to 65 [A], it will take

approximately 1 second to trip the motor protection due to the

contactor-current protection.

The contactor is worn out

LC 231 has a wear-out counter for the contactor(s) which are based

on the actual current when the motor is switched off by the

protection function.

When 90 % of the estimated wear-out for the contactor is reached,

the warning code 220 appears on the operating panel. In Grundfos

GO Remote, the warning

Contactor wear out

appears.

When 100 % of the estimated wear-out for the contactor is reached,

the alarm code 220

Contactor wear out

appears on the operating

panel and the controller will not be able to start the pumps.

The pump is blocked

To prevent that the contactor gets worn out too fast if the pump is

blocked, a maximum number of restarts are allowed by the

controller.

Maximum number of blocked motor restart

can be set

from 1 to 3 via Grundfos GO Remote. Tripped by the CCP-curve.

The alarm code 51 appears on the operating panel. In Grundfos GO

Remote, the alarm

Blocked

appears.

If the motor has reached the maximum numbers of restarts, 1 to 3

times, due to a blocked motor, it is possible to reset the failure up to

3 times manually. After that LC 231 will wait 24 hours before trying

to restart the motor again. Alternatively, switch off the main power

supply to LC 231 for a minimum of 30 seconds to clear the alarms.

A blockage alarm is typically triggered when the motor starts and in-

rush current trips the motor. The maximum allowed blockage

situations are limited to 6 times during a 24-hour period. If

the

Maximum number of blocked motor restart

is set to 3, the

control unit tries to restart the motor 3 times before a manual reset

is needed. If it occurs 3 times again after the reset, the control unit

has reached the maximum number of blockages.

Related information

6.17.4 Setting the motor protection with Grundfos GO Remote

6.18 Alarm reset

6.18.1 Resetting alarms and warnings manually with Grundfos

GO Remote

1.

Go to

Alarms and warnings

.

2.

Press

Reset alarm

.

All current alarms and warnings have been reset. However, if

the fault causing the alarm or warning has not been removed,

the alarm or warning will appear again.

3.

If you want to delete all alarms and warnings from the history

log, press

Show log

>

Reset alarm and warning logs

.

6.18.2 Setting the automatic alarm reset with Grundfos GO

Remote

1.

Go to

Settings

>

Automatic alarm reset

.

18

English (GB)

Summary of Contents for LC 231

Page 2: ......