A blue or grey circle with a white graphical symbol

indicates that an action must be taken.

A red or grey circle with a diagonal bar, possibly with a

black graphical symbol, indicates that an action must not

be taken or must be stopped.

If these instructions are not observed, it may result in

malfunction or damage to the equipment.

Tips and advice that make the work easier.

2. Installing the product

2.1 Location

Install the product in a location that meets the following

requirements:

•

Place the product in a flood-safe place.

•

Make sure that the ambient temperature is within the limits.

•

Install the product as close as possible to the connected

pumps, sensors, and accessories.

•

The product must be protected from direct sunlight.

•

The product must be easily accessible.

•

We recommend that you install the product in a protective shed

or enclosure to avoid direct sunlight and rain.

•

Indoor installation: The product must be installed in a well-

ventilated room to ensure cooling of its components.

2.2 Mechanical installation

2.2.1 Mounting the rubber seals

1.

Mount the supplied rubber seals on the cable glands.

TM074473

2.

Mount the cable glands on the control unit.

TM074474

Do not tighten the cable glands too much since this

may damage the rubber seals.

Related information

2.3.3 Connecting the pump supply and power supply

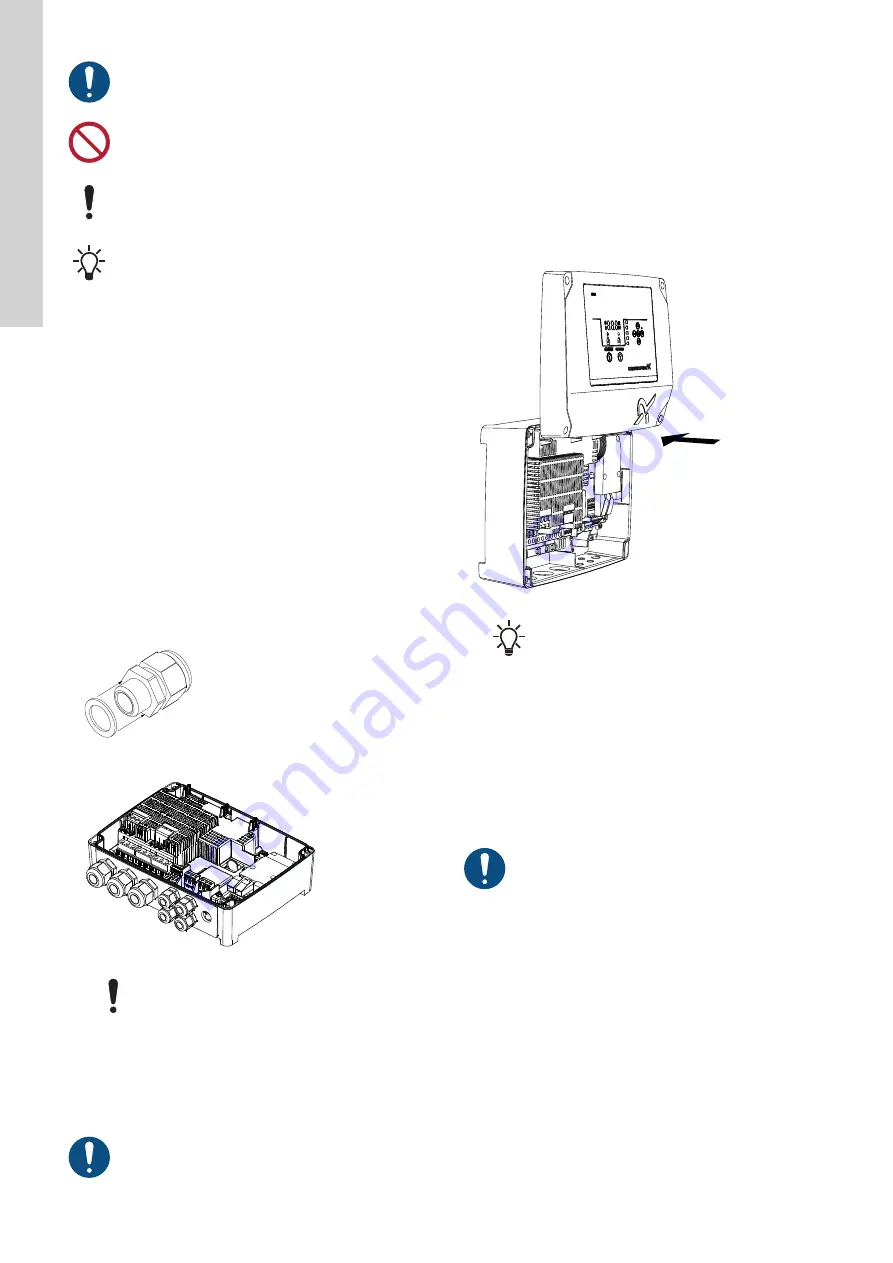

2.2.2 Removing the front cover

The front cover must be removed to make any connections or to

install the Communication Interface Module (CIM).

Use an antistatic service kit when handling electronic

components. This prevents static electricity from

damaging the components.

Place the front cover above the control unit, if possible. This way

you do not need to remove the flat cable between the front cover

and the control unit.

1.

Loosen the screws.

2.

Carefully separate the front cover from the back cover.

Be careful not to damage the cable connecting the front cover

and the back cover.

3.

Place the front cover above the back cover on the support

brackets.

4.

To ensure that the front cover does not tilt, insert the two

bottom screws into the open holes at the top of the back cover.

TM071322

When you mount the front cover again, tighten the

screws to 1.25 Nm.

Related information

2.2.4 Installing the control unit

2.2.5 Installing a communication interface module

2.3.4 Connecting a level sensor

3.6 Configuring the IO terminals using Grundfos GO Remote

2.2.3 Disconnecting the front cover

If you need to remove the front cover completely, you must remove

the flat cable between the front cover and the back cover.

Use an antistatic service kit when handling electronic

components. This prevents static electricity from

damaging the components.

1.

Loosen the screws.

2.

Carefully separate the front cover from the back cover.

6

English (GB)

Summary of Contents for LC 231

Page 2: ......