4.

Choose one of the following options:

•

Auto

•

Off

.

5.

Go one step back in the menu and select

Forced start time

.

6.

Set the time period in which the pump must run in manual

operating mode.

Related information

6.16.2.2 Starting and stopping the pump manually with the

operating panel

6.16.2.1 Starting and stopping the pump manually with Grundfos

GO Remote

6.17 Motor protection

Make sure that all settings are entered according to the

pump and system requirements to avoid malfunction.

6.17.1 Overheat protection

The control unit offers thermal protection for the connected motors.

Two types of thermal-protection sensor can be connected to the

control unit: a PTC sensor (analog) and a thermal switch (digital).

Under normal running conditions, the sensor will act as a short

circuit, but when its temperature limit is reached, it will open and tell

the control unit that the temperature is too high, and the pump is

stopped. When the temperature has dropped to the sensor-trigger

level, the pump will return to normal running conditions. It will not be

possible to start the pump manually as long as the temperature is

too high.

Related information

6.14 Setting the maximum number of restarts with Grundfos GO

Remote

6.17.4 Setting the motor protection with Grundfos GO Remote

8.13 Code 69 (Winding temperature too high)

6.17.2 Overload protection

The pump is protected by internal software-based motor protection.

Related information

6.14 Setting the maximum number of restarts with Grundfos GO

Remote

6.17.4 Setting the motor protection with Grundfos GO Remote

8.9 Code 48 (Motor is overloaded)

6.17.3 Moisture protection

When a moisture sensor is installed in series with the temperature

sensor, the control unit needs to know how to determine whether

there is a high temperature or moisture in the pump. If the

temperature is too high, normally the temperature sensor will go

back to its normal stage when the temperature has dropped to its

trigger level. If there is moisture in the pump, then the moisture

sensor will keep the series connection open until the pump is

opened and serviced.

To determine which sensor has been active, a

cool down

time

must be entered. This is the time that will normally pass until

the temperature has dropped enough for the temperature sensor to

return to its normal stage. If the

cool down time

is exceeded, the

control unit will assume that there is moisture in the pump, and it

will send a moisture alarm.

Related information

6.17.4 Setting the motor protection with Grundfos GO Remote

6.17.4 Setting the motor protection with Grundfos GO Remote

You can set the current, temperature and moisture protection via a

setup wizard.

1.

Go to

Settings

>

Motor protection pump 1

or

Motor

protection pump 2

.

2.

Follow the on-screen wizard to set the following:

•

Nominal pump current

•

Trip IEC class

•

Pump connection

•

Overheat protection

.

Related information

2.3.3 Connecting the pump supply and power supply

6.14 Setting the maximum number of restarts with Grundfos GO

Remote

8.26 Code 220 (Contactor wear out)

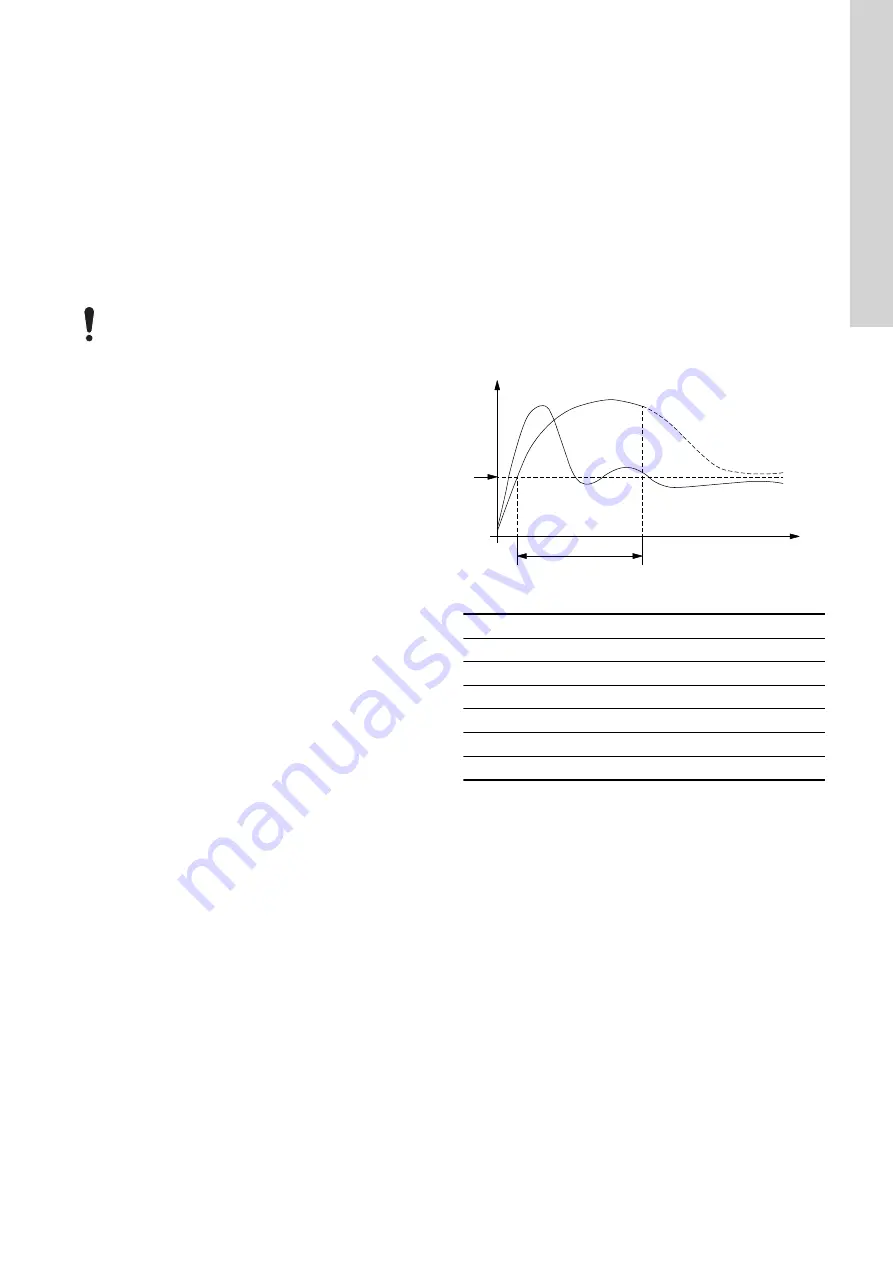

6.17.5 Trip class

The trip delay indicates the maximum period of time during which

the overload condition is allowed to exist within a period of 0.1 - 30

seconds.

3

4

1

2

Y

X

TM072271

Curves for trip class "P

Pos.

Description

Y

Current

X

Time

1

Rated motor current

2

10-second trip delay

3

Curve with tripping

4

Curve without tripping

A pump is to cut out after 10 seconds because the rated current has

been exceeded.

1.

Select trip class.

2.

Set the overload limit to 10 A. The rated motor current is stated

on the nameplate.

See position 3, curve with tripping. LC 231 cuts out the pump

because the pump startup time exceeds 10 seconds and the

current exceeds 10 A.

See position 4, curve without tripping. During pump startup the

starting current only briefly exceeds 10 A and the pump is not cut

out.

17

English (GB)

Summary of Contents for LC 231

Page 2: ......