For the US market only, use flexible metal conduits (FMC)

only.

Changes or modifications not expressly approved by

Grundfos may void the user's authority to operate the

equipment.

Cable cross-sections

Type of cable

Stranded with ferrule Solid

Cross-section

[mm

2

]

[AWG]

[mm

2

] [AWG]

Contactor for the pump

1.5 - 2.5

16-14

1.5 - 4

16-12

Terminal block for the

power supply

2.5 - 10

14-8

2.5 - 16 14-6

2.3.2 Protection of controller and supply cables

The controller and power cables must be overload-protected. The

protection must be accomplished using components such as:

•

fuse of melt type gL and gG

•

fuse type gD

•

circuit breaker of type C.

See the rated current for this specific product on the product

nameplate.

Related information

2.3.3 Connecting the pump supply and power supply

Pumps are typically equipped with PTC/Klixon sensors (thermal

switched) which protect against overheating.

Some also have moisture sensors indicating water in the pump.

DANGER

Electric shock

Death or serious personal injury

‐

If national legislation requires a Residual-Current

Device (RCD) or equivalent in the electrical installation,

this must be of at least type B, due to the nature of the

constant DC leakage current.

WARNING

Electric shock

Death or serious personal injury

‐

Switch off the power supply before making any

electrical connections. Make sure that the power

supply cannot be switched on accidentally.

‐

Remember to indicate where the main switch is

located by placing a label or similar on the control unit.

‐

Make sure that the voltage between the phase and

neutral does not exceed 250 VAC.

‐

Electrical connections must be carried out according to

the wiring diagrams.

Do not add additional components other than those

illustrated on the wiring diagram. Do not use unused pin

holes for other connections.

All cable glands and plugs must be mounted after the

installation is completed.

If the gaskets are not pre-mounted on the cable glands,

mount them on the cable glands before the control unit is

mounted on the wall.

For the PTC connection, do not connect the third wire

(common wire). It must be isolated with a cable-end cap.

The residual-current circuit breaker must be marked like this:

TM066230

Take into account the total leakage current of all the electrical

equipment in the installation.

1.

Check that the supply voltage and frequency correspond to the

values stated on the nameplate.

2.

Cut the power supply and pump cables as short as possible.

3.

Before switching the power on, check all voltages with a

multimeter and ensure that the voltage between neutral and

each phase does not exceed 250 VAC.

4.

Connect the power cables and pump cables according to the

relevant electrical diagram, including the cables from the motor

temperature and moisture sensor, if any. Tighten the terminal

screws to the correct torque. See table.

Note that all wires must be secured inside the cabinet using

cable ties. All cable glands must be mounted and

plugged, even if they are not in use, to ensure the correct IP

protection level.

Remember to remove the jumper from the PTC terminal if you

are connecting cables from the temperature sensor to the PTC

terminals.

Terminal block

Torque [Nm]

Pump contactor

1.2 - 1.5

Power supply

1.2 - 1.5

Cable glands

2.5

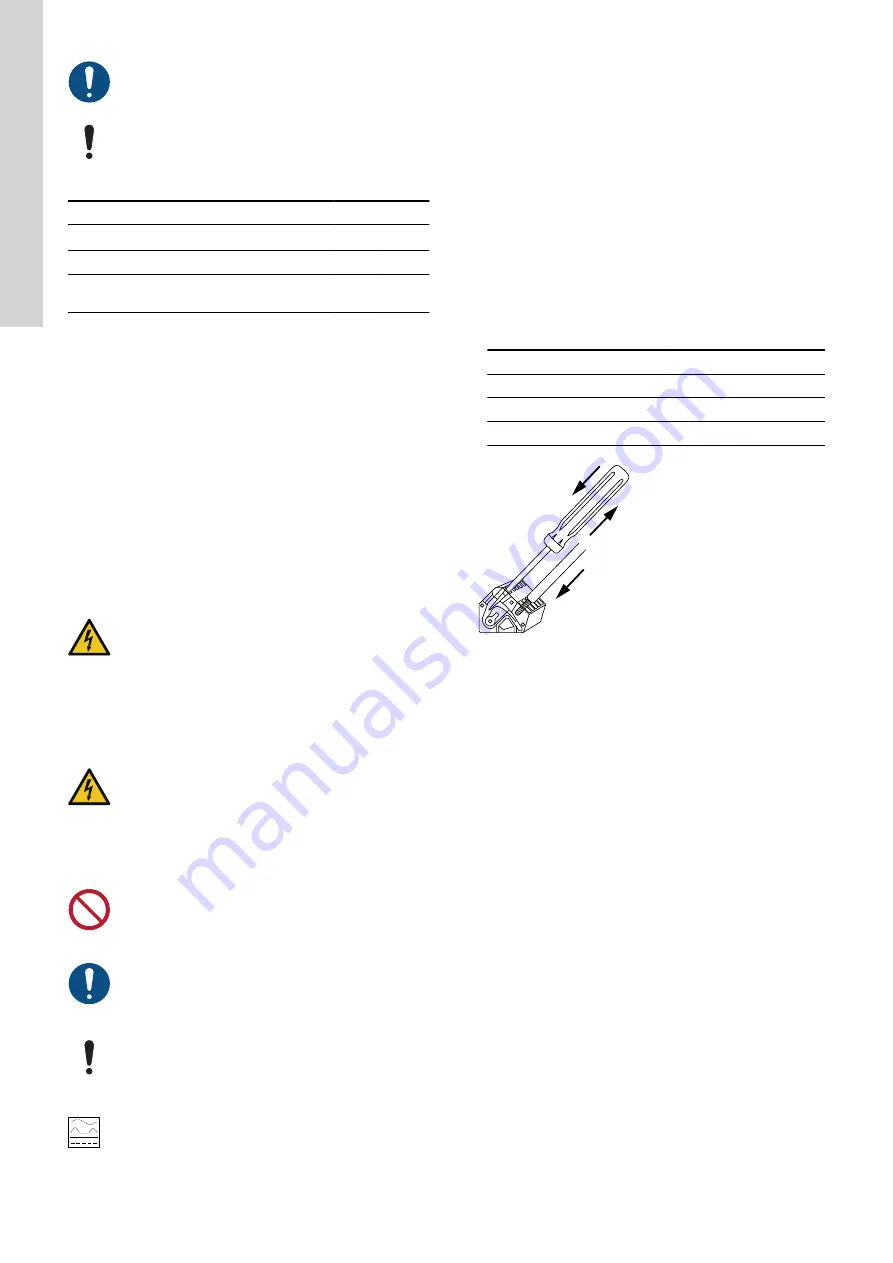

TM070570

Connecting a wire to a terminal with spring clamps

5.

Tie the pump phase cable(s) to the protection cover with cable

ties.

6.

In case there is only a PTC sensor present in the pump, the

two wires from the PTC sensor have to be connected directly to

the PTC terminals.

8

English (GB)

Summary of Contents for LC 231

Page 2: ......