English (GB)

9

7.8 Replacing the power module

If the power module is replaced, the entire bottom of the terminal

box must be replaced.

1. Disconnect the power supply.

2. Remove the terminal box cover. See section

.

3. Remove the control panel (290) from the isolating cover (277).

See section

7.4 Replacing the control panel

4. Remove the CIM module (502) from the isolation cover. See

section

.

5. Remove the isolation cover. See section

.

6. Remove the functional module. See section

.

7. Pull out the plug connection (266).

8. Remove the screws (178) from the terminal box (251a) and

gently lift the terminal box off the motor (150).

9. Fit the new terminal box on the motor. Make sure that the plug

connections are aligned.

10. Cross-tighten the screws of the terminal box.

11. Fit the plug connection for power supply.

12. Fit the functional module. See section

.

13. Fit the isolation cover. See section

14. Fit the CIM module. See section

15. Fit the control panel. See section

.

16. Fit the terminal box cover. See section

.

17. Calibrate the functional module with the power module. See

section

7.15 Configuring the controller

.

7.9 Replacing the terminal box

1. Disconnect the power supply.

2. Remove the terminal box cover. See section

3. Disconnect all relevant wires.

4. Remove the screws (178) from the terminal box (251a) and

gently lift the terminal box off the motor (150).

5. Fit the new terminal box on the motor. Make sure that the plug

connections are aligned.

6. Cross-tighten the screws of the terminal box.

7. Move relevant modules to the new terminal box according to

the section above.

8. Connect all relevant wires.

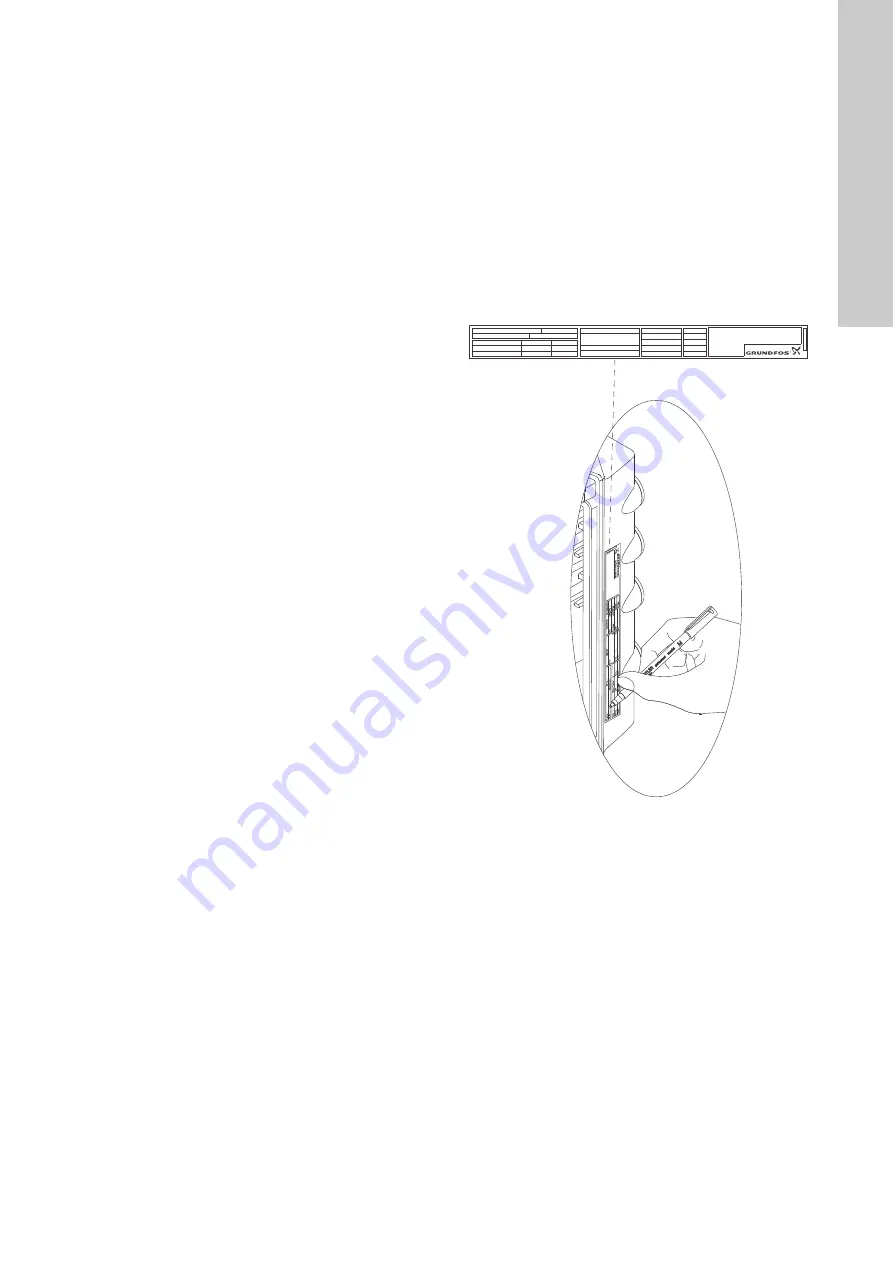

9. Transfer data from the nameplate of the old terminal box to

the nameplate of the new one.

Fig. 11

Transferring data to new nameplate

10. Fit the terminal box cover. See section

TM0

5

695

4

0

3

1

3

Env.Type :

Serial no :

IP

CL:

PF:

PB

FM

HMI

Eff

n max:

CIM

Wgt :

DE :

kg

NDE :

T

amb

:

:

C

A

V

~

P.C. :

Made in Hungary

OUTPUT

VARIANT

INPUT

Type :

P.N. :

U in

:

I

1/1

:

f in

kW

Hz

P2

rpm

:

:

:

:

:

:

:

o

DK - 8850 Bjerringbro, Denmark

Summary of Contents for MGE 100

Page 1: ...MGE and MLE model J Service instructions GRUNDFOS INSTRUCTIONS ...

Page 2: ...2 ...

Page 30: ...English GB 30 10 Exploded view Fig 68 MGE model J MGE 132 TM06 6857 2516 ...

Page 32: ...32 ...

Page 33: ...33 ...

Page 34: ...34 ...