Float switches used in

potentially explosive en-

vironments must be ap-

proved for this applica-

tion. They must be

connected to the Grund-

fos LC 231 or LC 241

level controller by an in-

trinsically safe barrier to

ensure a safe circuit. In

potentially explosive en-

vironments, the anti-

seizing function must be

disabled on the pump

controllers.

Thermal switch, PT1000 and thermistor (PTC)

Explosion-proof pumps

The thermal protection

of explosion-proof

pumps must not restart

the pump automatically.

This ensures protection

against overtemperature

in potentially explosive

environments. In pumps

with sensor, this can be

done by removing the

short circuit between ter-

minals R1 and R2 in the

IO 113.

See electrical data in the IO 113 installation and

operating instructions.

Do not install the sepa-

rate motor-protective cir-

cuit breaker or control

box installed in potential-

ly explosive environ-

ments.

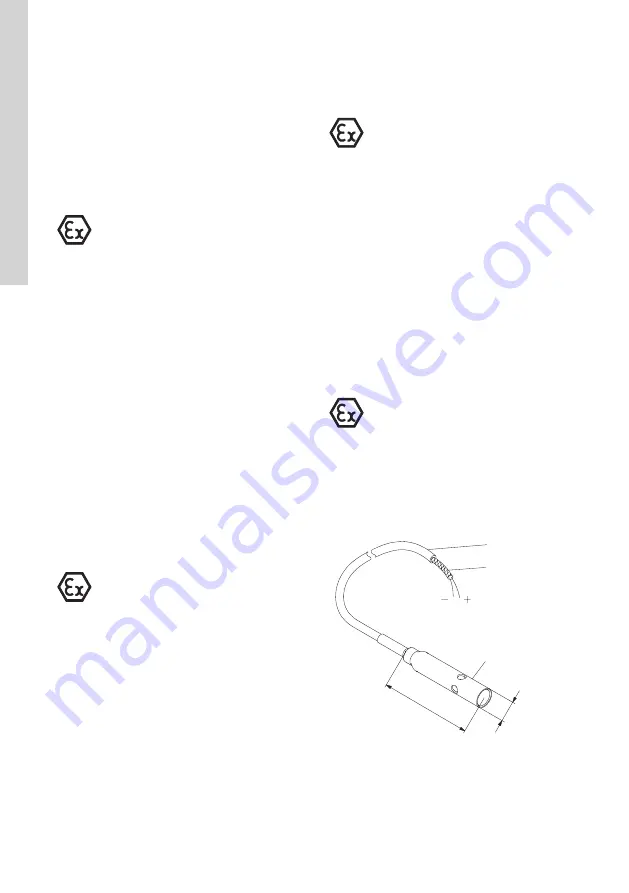

WIO sensor

The WIO sensor measures the water content in the

oil and converts the value into an analog current

signal. The two sensor conductors are for power

supply as well as for carrying the signal to the IO 113.

The sensor measures the water content from 0 to 20

%. It also sends a signal if the water content is

outside the normal range (warning), or if there is air in

the oil chamber (alarm).

The IO 113 module must

be configured to stop ex-

plosion-proof pumps in

case the WIO sensor

sends an alarm signal.

The pump must not re-

start automatically.

The sensor is fitted in a stainless steel tube for

mechanical protection.

3

2

1

59

12

TM031

164

20

English (GB)

Summary of Contents for SE1 100

Page 2: ......