14

English (US)

7.2 Cleaning the pump

If the pump does not deliver a sufficient quantity of

water because of sediment, dismantle and clean the

pump.

7.2.1 Cleaning the inlet strainer

1. Disconnect the power supply to the pump.

2. Drain the pump.

3. Loosen the inlet strainer by inserting a

screwdriver in the recess between the pump

housing and the strainer.

4. Use the screwdriver to push apart the outer

housing and the strainer. Repeat the procedure,

working around the pump, until the strainer is

free and can be removed.

5. Clean and refit the inlet strainer.

Cleaning the impeller

1. Disconnect the power supply to the pump.

2. Drain the pump.

3. Loosen the inlet strainer by inserting a

screwdriver in the recess between the pump

housing and the strainer,

4. Use the screwdriver to push apart the outer

housing and the strainer. Repeat the procedure,

working around the pump, until the strainer is

free and can be removed.

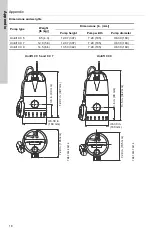

5. Remove the strainer and the bottom part of the

pump housing as shown in fig.

Fig. 17

Removal of the strainer and the bottom

part of the pump housing

6. Remove and clean the diaphragm.

7. Clean and flush the pump with clean water to

remove possible impurities between the motor

and the pump housing. Clean the impeller.

8. Check that the impeller can rotate freely.

9. Assemble the pump in reverse order of

dismantling.

7.3 Service kits

The impeller assembly and power cable can be

replaced. The part numbers and the components

included in the service kits are found in Grundfos

Product Center at www.grundfos.us. Alternatively,

contact your local Grundfos dealer or service center.

7.4 Contaminated pumps

Any application for service, no matter to whom it may

be made, must include details about the pumped

liquid.

The product will be classified as contaminated if it

has been used for a liquid which is injurious to health

or toxic.

If you request Grundfos to service the product,

contact Grundfos with details about the pumped

liquid before returning the product for service.

Otherwise Grundfos can refuse to accept the product

for service.

Any application for service must include details

about the pumped liquid.

Clean the product in the best possible way before

you return it.

Costs of returning the product are to be paid by the

customer.

T

M

03

1

112

10

05

The cable and the float switch must

be replaced by a service workshop

authorized by Grundfos.

CAUTION

Biological hazard

Minor or moderate personal injury

- Flush the pump thoroughly with

clean water and rinse the pump

parts in water after dismantling.