9. Control functions

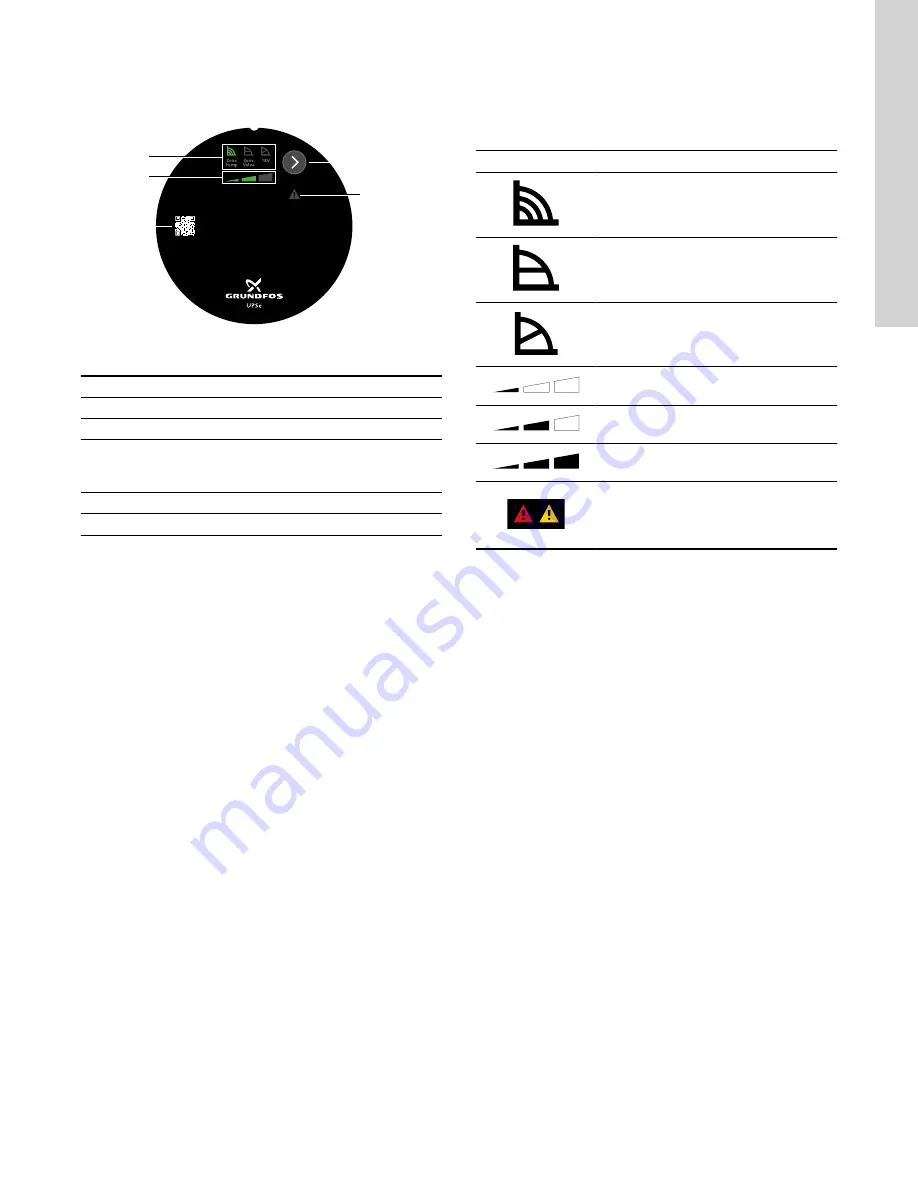

9.1 Operating panel, UPSe

1

4

5

2

3

TM082448

Operating panel

Pos.

Description

1

Control mode

2

Setting (I, II, III)

3

QR code

When scanning the QR code, you get access to

additional product information and documentation.

4

Button for changing control mode and setting

5

Warning and alarm symbol

The operating panel offers quick access to change the control

mode.

The menu includes three control modes each with three pump

settings:

•

Zone pump (constant curve)

•

Zone valve (constant pressure)

•

TRV (thermostatic radiator valve) (proportional pressure).

Related information

9.2 Light fields indication

The LEDs indicate the control mode and setting.

Factory setting

The pump is factory set to Zone pump, setting III.

Active light fields

Description

Zone pump (constant curve)

Zone valve (constant pressure)

TRV (thermostatic radiator

valve) (proportional pressure)

Setting I

Setting II

Setting III

Fault indication (warning = yellow / alarm =

red)

If the alarm indication is on, the pump is

stopped.

13

English (US)