English (GB)

18

5.2.3 Checking the tightness of pressure gas lines

Pressure gas lines are all lines from the gas containers to the

vacuum regulator.

• If the plant is equipped with a nitrogen rinsing device:

Check tightness roughly with nitrogen.

• Detailed checking with amonia.

Checking the tightness with nitrogen

• Close all container valves

• Open container connection valves and all shut-off valves up to

the gas dosing system

• Open the connection valve of the nitrogen cylinder

• Slowly open the valve of the nitrogen cylinder, until the lines

have a pressure of about 10 bar (read at the manometer of

the vacuum regulator).

• Apply soap water to all components under pressure

– Formation of bubbles and/or pressure drop at manometer:

Leakage in pressure lines!

Depressurize the plant!

Eliminate leakage!

Check tightness again!

No formation of bubbles, pressure at manometer does not drop

significantly within one hour: Pressure lines are tight.

Checking the tightness with ammonia

• Open all container valves and container connection valves and

quickly close them again

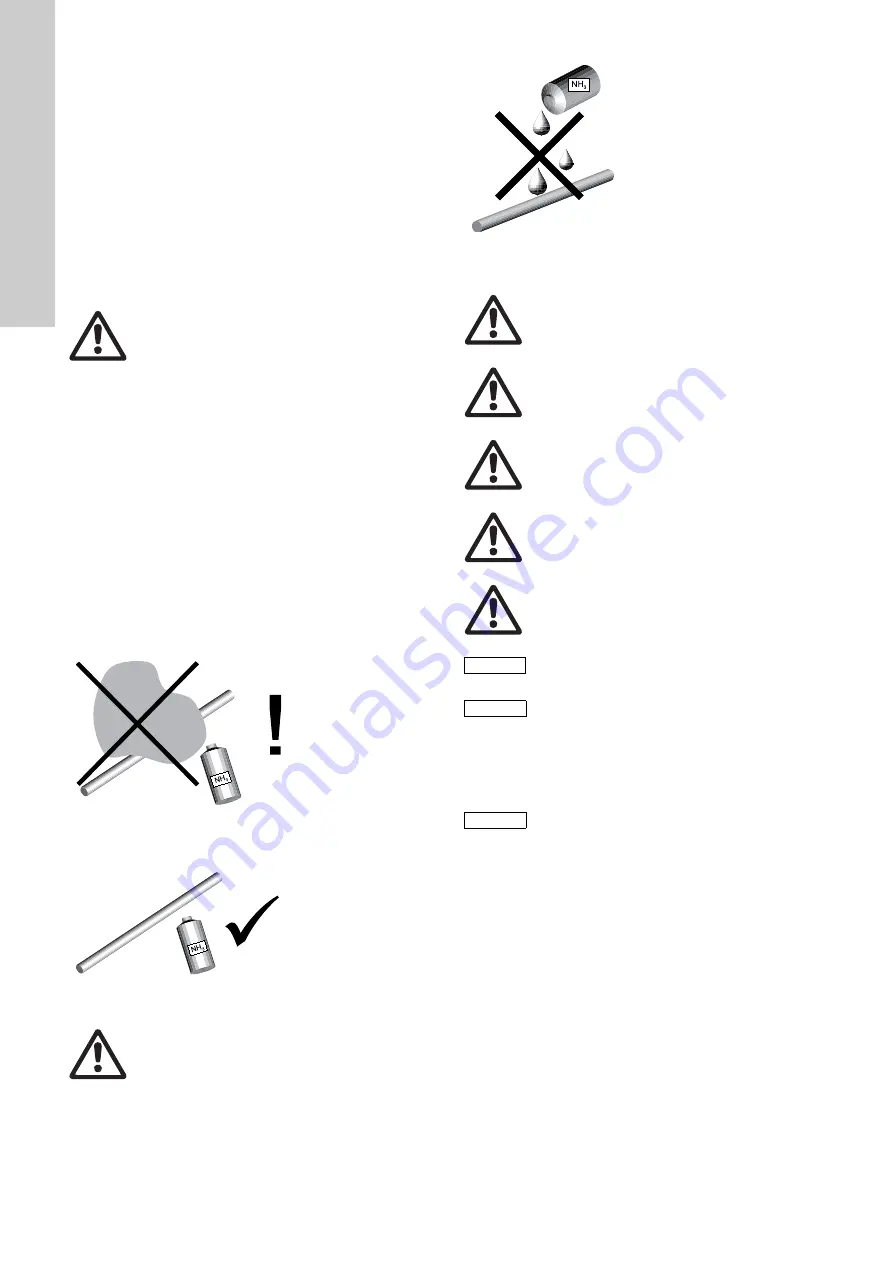

• Slowly pass the open ammonia bottle along pressure-gas

leading parts

• Formation of white mist:

Leakage in pressure lines!

Depressurize the plant!

Eliminate leakage!

Check tightness again!

Fig. 27

Formation of white mist: Leakage in pressure lines!

– No formation of white mist: Pressure lines are tight.

Fig. 28

No formation of white mist

Fig. 29

Danger of leakages

5.2.4 Servomotor tests

5.2.5 Checking the servomotor's direction of rotation

The servomotor is controlled by an external controller. This

means that the servomotor's direction of rotation depends on the

controller's cabling and settings being correct.

Warning

Maximum nitrogen pressure 16 bar!

Danger of damages and chlorine break-out when

being exceeded!

T

M

04

08

49

09

08

T

M

04

06

97

09

08

Warning

Liquid ammonia must not come in contact with parts

of the plant!

Danger of leakages by corrosion!

T

M

04

06

98

09

08

Warning

The drive may only be commissioned if the hood and

cable entries are properly closed.

Warning

Please note that the process of commissioning the

drive will cause associated fittings/levers/rodding to

move.

Warning

Check that all the emergency equipment/functions on

your installation are working correctly.

Warning

Once all adjustment work has been completed,

check that the drive and the fittings/levers, etc.

operated by it are working correctly.

Warning

Never work with a damaged drive.

Caution

When commissioning, all the installation's

components must be ready for operation.

Note

Follow the installation and operating instructions for

the components used.

Note

Observe the installation and operating instructions

for the controller and the gas dosing system.