English (GB)

19

6. Operation

6.1 Description of the system

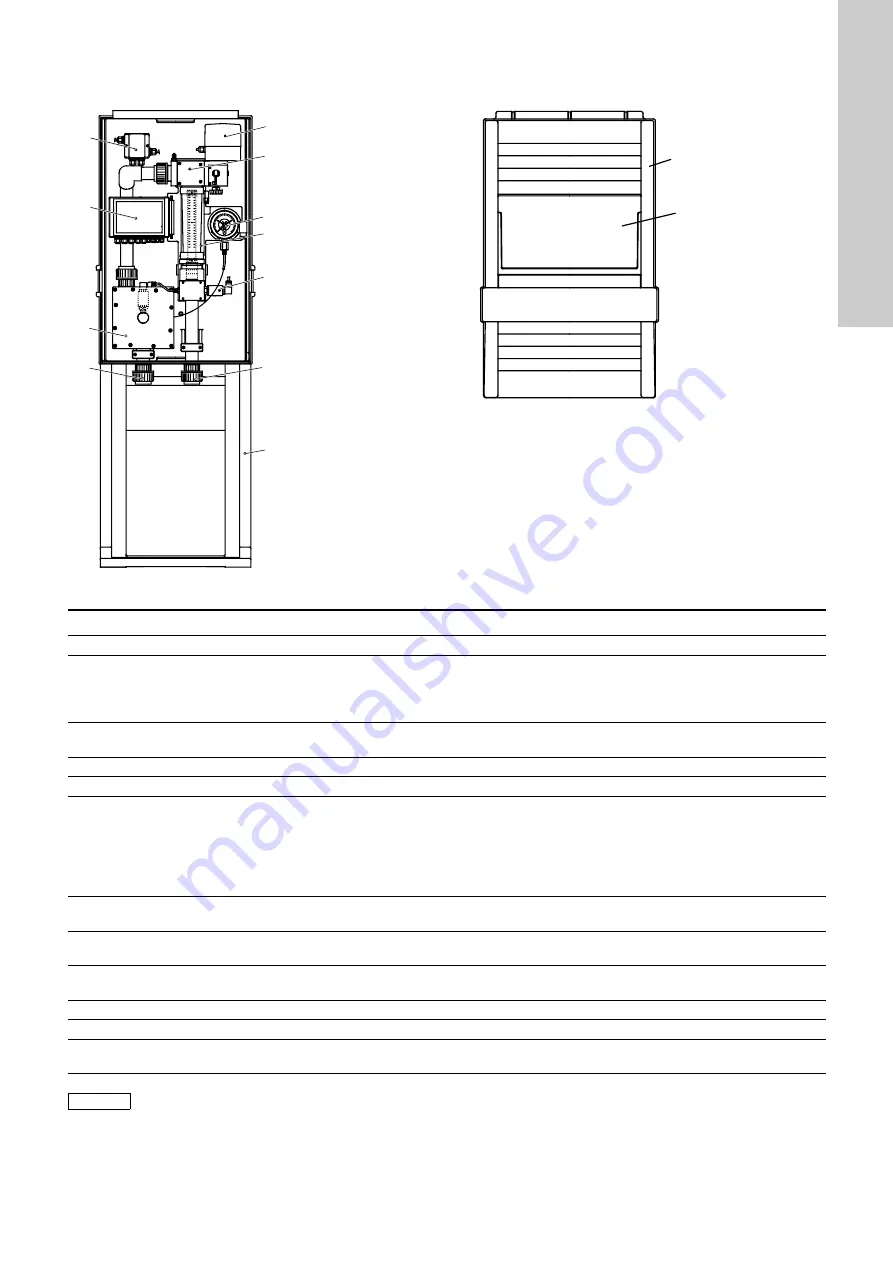

Fig. 30

Functional scheme VGS-141, -143, -145

Fig. 31

Front hood to take off, with swing-out clear vision flap

TM

04 08

19 491

7

1

2

3

4

5

6

8

7

9

10

11

T

M

04

0

8

2

0

49

17

17

18

Item Component

Description

1

Line to the injector

2

Differential pressure regulator

It regulates the difference of the pressures before and after the rate valve to a

constant value.

• Adjusted dosing flow stays constant, even when the injector vacuum fluctuates.

• with electronic vacuum sensor (option)

3

Electronics (option)

Measuring amplifier for the chlorine concentration Conex

®

DIA-2Q or Conex

®

DIS-2Q

• amplifies the signal of the optional measuring cell

4

Clamp box (option)

5

Servomotor

6

Rate valve

Adjusting the desired gas flow

• manually with the hand wheel

or

• automatically with an electrical servomotor (5) (option)

• servomotor can optionally be equipped with a 4 - 20 mA signal input for

proportional control (no further electronics necessary)

7

Measuring tube

Displays the gas flow

• with magnetic detection of the floater position (option)

8

Vacuummeter

Displays the injector vacuum

• with limit contacts (option)

9

Sensor for the operation vacuum

(option)

For measuring the vacuum at the inlet of the gas dosing system

10

Line from the vacuum regulator

11

Foot

17

18

Front hood (17) to take off, with swing-

out clear vision flap (18)

Caution

The rate valve is not a perfectly closing shut-off

valve!