k

3 - 2

GRUNDIG Service

Adjustment Procedures

GV 29…, GV 9000…, GV 9300…

GB

Adjustment Procedures

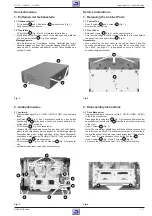

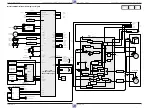

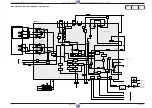

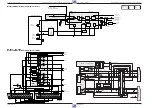

1. Chassis Board

View of Solder Side

TP182

TP183

IC301

C3016

Test equipment / aids: Two-channel oscilloscope with 10:1 probes, voltmeter, colour generator, test cassette, branded video cassette

Service works on replacement of …

… the tape drum: Adjustment No. 1, 2

… IC304: Adjustment No. 1, 2

Adjustment

Preparation

Adjustment Procedure

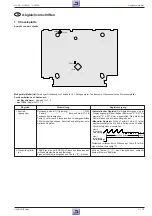

1. Headwheel

Position Indicator

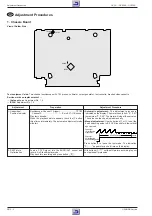

2. Still Picture

Optimisation

• Automatic adjustment: The adjustment process is

indicated on the display. The meter counts from "P: 0:01"

to maximum "P: 2:55". The meter will stop at the set value.

The value can then be adjusted manually.

• Manual adjustment: Use the buttons

Ü

or

*

to set the

head switching pulse to 6.5

±

0.5 lines before the vertical

sync pulses.

6.5

±

0.5H (lines)

V-sync

Channel 1:

2V/div 50

µ

s/div

Head switching pulse

Channel 2:

1V/div 50

µ

s/div

Video output

Press button

u

to leave the test mode. The indication

"P:– : –" appears for a short time on the display.

With buttons

C

/

D

set the still picture according to your

best personal impression.

Oscilloscope: Channel 1 (trigger): .......................... TP183

Channel 2: ................................. Euro-AV1-(19) socket

Play test cassette.

When the playback picture appears touch the

K

button

three times immediately. The automatic adjustment mode

will start.

Feed a CCVS signal into the EURO-AV1 socket and

record it in Standardplay mode.

Play back this recording and press button

Ó

.