4. Electric Operated Gate Installation

36

PNEG-1993

CE Compliant E-Series Chain Conveyors - All Models

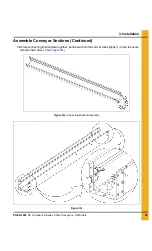

Install Gate to Trough Bottom of Intermediate Gate and Head Gate

1. Attach the gate (A) to the connection flanges and trough bottom using supplied hardware (B and C).

2. Seal all connections with a silicon based caulk to make weather-resistant.

Figure 4G

Ref #

Description

A

Gate

B

Bolt

C

Nut

D

Conveyor

Head gate section

Intermediate gate section