INSTALLATION

12

PNEG-1521

Commercial Direct Gear Drive Bin Sweep Auger

FIG. 1- A FLOOR VIEW

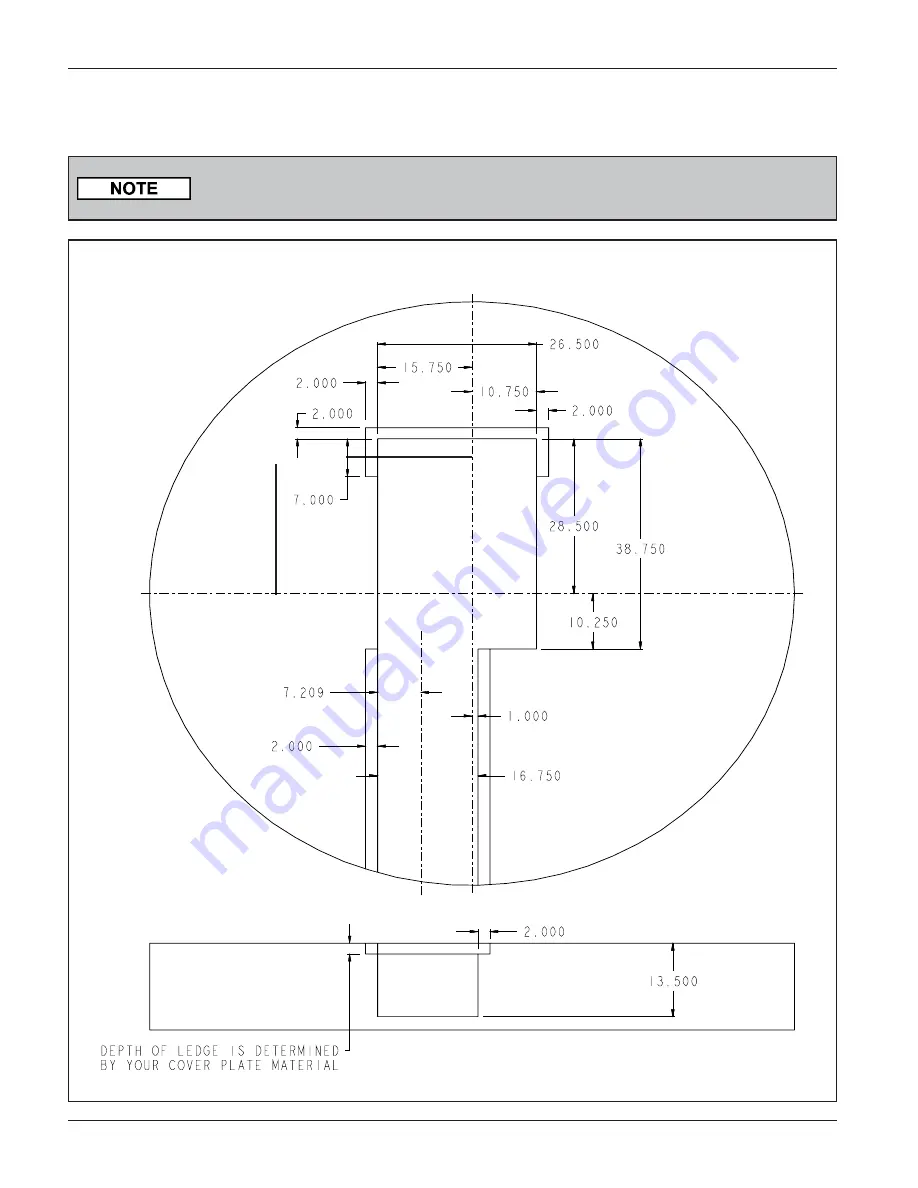

The company does not recommend setting the Direct Gear Drive Bin Sweep

unit in concrete. If installing a unit flush with a concrete floor, we recommend

the unit be installed in a preformed trench. Use the diagram below .

1. POWER SWEEPS IN BINS WITH CONCRETE FLOORS

Center of Bin

TOP VIEW

SIDE VIEW

CONCRETE TRENCH LAYOUT