48

Fan and Heater

HEATER SERVICE

All Airstream heaters are constructed of durable

weather-resistant materials, so a minimum amount

of service should be required; however before the

unit is started for the first time each season there

are a few items that need to be checked out. All

damaged parts should be repaired or replaced.

1. Disconnect and lock out power to fan and heater.

Open control box lid and inspect all compo-

nents for moisture, vibration or rodent damage.

Inspect and tighten all loose terminal con-

nections. Replace any damaged wiring.

2. Remove burner orifice tube and inspect for dirt

or foreign material. Clean out if necessary.

3. Inspect burner for wear or foreign material in

any of the ports. Clean or replace parts if necessary.

4. Inspect the spark plug and flame probe for cor

rosion and damage. Clean or replace if necessary.

5. All control boxes and components should be

checked yearly for signs of moisture accumulat

ion. Any moisture will affect microprocessor con

trol system used on this heater. The conduit and

control boxes are particularly susceptible and

should be checked frequently. Any accumula

tion of dirt or foreign material can also cause

problems with the electrical system.

The Series 2000 control box.

Summary of Contents for PNEG-377

Page 1: ...Fan And Heater PNEG 377 Service Manual 2 0 0 0 EDITION...

Page 2: ......

Page 6: ...6 Fan and Heater...

Page 7: ...7 Fan and Heater 2000 VANE AXIAL FANS...

Page 9: ...9 Fan and Heater TEST STATION...

Page 14: ...14 Fan And Heater FAN WIRING AND SCHEMATIC Wiring 240 Volt 1 Phase 15 HP Schematic...

Page 17: ...17 Fan And Heater 2000 CENTRIFUGAL FAN SERVICE GUIDE...

Page 24: ...24 Fan and Heater 2000 Gas Heater Service Guide...

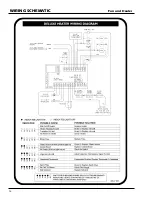

Page 49: ...49 Fan and Heater WIRING DIAGRAM...

Page 56: ...56 Fan and Heater WIRING SCHEMATIC...

Page 57: ...57 Fan and Heater STANDARD HEATER WIRING...

Page 58: ...58 Fan and Heater STANDARD HEATER SCHEMATIC...

Page 61: ...61 Fan and Heater NOTES Notes...

Page 62: ...62 Fan And Heater 1996 1994 Gas Heaters...

Page 63: ...63 Fan And Heater DELUXE HEATER WIRING...

Page 64: ...64 Fan And Heater DELUXE HEATER SCHEMATIC...

Page 65: ...65 Fan And Heater DELUXE HEATER SCHEMATIC 1993 1995 Heaters...

Page 70: ...70 Fan and Heater 1991 1993 GAS HEATERS...

Page 72: ...72 Fan And Heater WIRING SCHEMATIC 1991 1992 Heaters...

Page 73: ...73 Fan and Heater 1990 GAS HEATERS...

Page 76: ...76 Fan and Heater PRE 1990 GAS HEATERS...

Page 77: ...77 Fan and Heater HEATER WIRING DIAGRAM...

Page 78: ...78 Fan and Heater HEATER SCHEMATIC Vane Axial LP Heater...

Page 79: ...79 Fan and Heater HEATER SCHEMATIC Vane Axial Vapor Heater...

Page 80: ...80 Fan and Heater HEATER SCHEMATIC Downwind LP Heater...

Page 81: ...81 Fan and Heater HEATER SCHEMATIC Downwind Vapor Heater...

Page 82: ...82 Fan and Heater HEATER SCHEMATIC Lo Fire Downwind Heater...

Page 83: ...83 Fan and Heater MISCELLANEOUS INFORMATION...

Page 93: ...93 Fan and Heater FENWAL SERIES 05 14 Figure 2 Figure 3...

Page 97: ...97 Fan And Heater...

Page 98: ...1004 E Illinois St Assumption IL 62510 Phone 217 226 4421 Fax 217 226 4498 February 2000...