12

PNEG-681

Series II Bucket Elevator

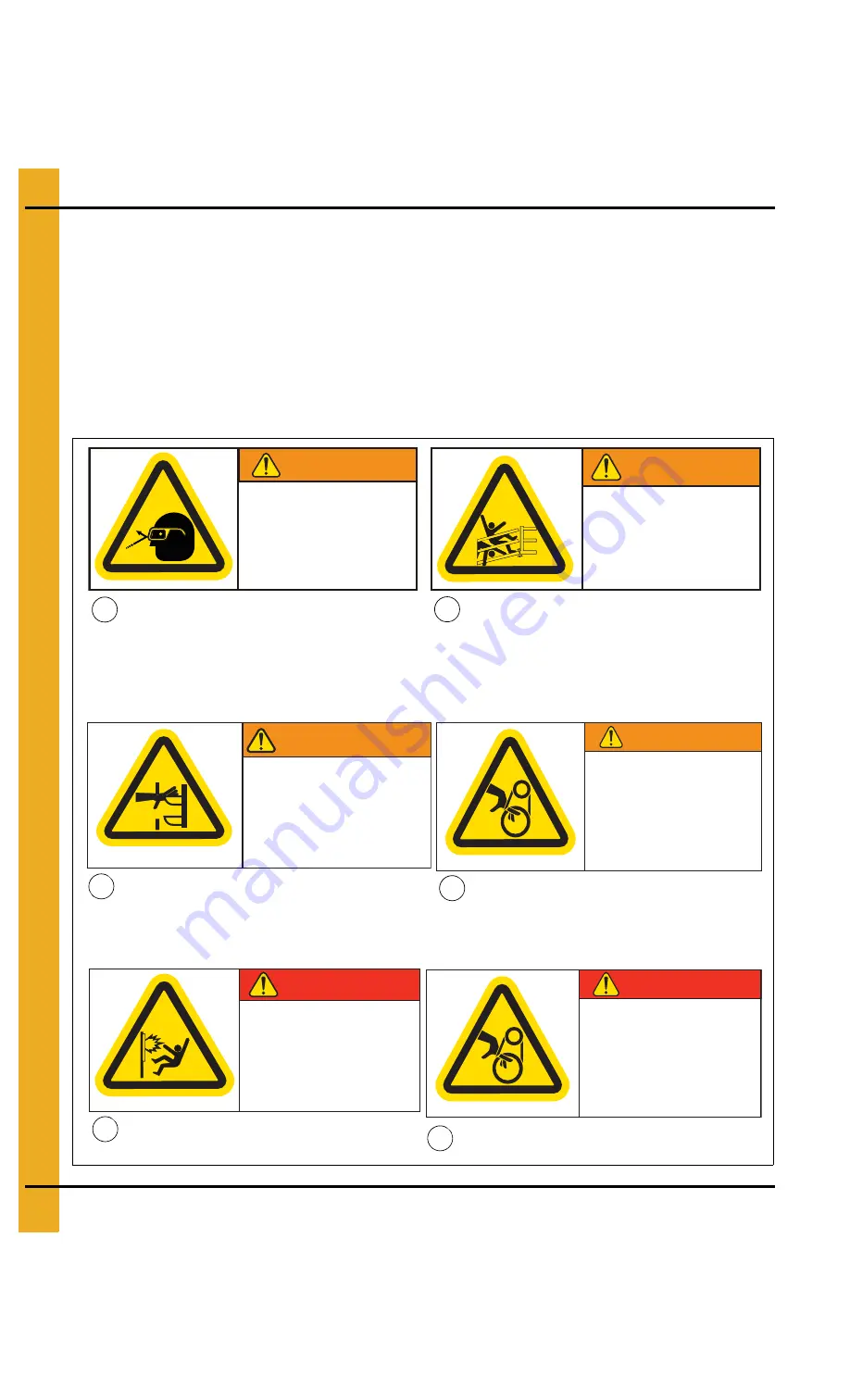

3. Safety Decals

Safety decals should be read and understood by all people in the grain handling area. Safety decals have

been affixed to the equipment to warn of danger to people and of possible equipment damage. These

decals must not be removed, tampered with, painted over or obscured in any way. If labels are damaged

or become unreadable, replacement labels are available from the manufacturer.

If a decal is damaged or is missing, contact:

GSI Decals

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 1-217-226-4421

A free replacement decal will be sent to you. (Refer to DC number on the decal.)

DC-1199

GSI Group Inc. 217-226-4421

DC-1199

WARNING

CRUSH HAZARD

Keep hands clear of

moving parts.

Do not operate with guard

removed.

Disconnect and lockout

power before servicing.

DC-1198

Thrown or flying

objects.

Eye protection

required.

WARNING

GSI Group 217-226-4421

DANGER

DANGER

Explosion release will

cause severe injury or

death. Avoid area

around explosion vent

during operation.

DC-1377

GSI Group Inc. 217-226-4421

WARNING

Platform collapse can

cause serious injury.

Do not exceed 500 lb.

maximum load.

DC-1378

GSI Group 217-226-4421

WARNING

SHEAR POINT

Keep hands clear of moving

parts. Do not operate with

guard removed. Disconnect

and lockout power before

servicing.

DC-995

GSI Group Inc. 217-226-4421

DANGER

DANGER

SHEAR POINT

Keep hands clear of moving

parts. Do not operate with

guard removed. Disconnect

and lockout power before

servicing.

DC-994

GSI Group Inc. 217-226-4421

DC-1198

DC-1377

DC-1378

DC-995

DC-994

1

2

4

3

5

6