4. Assembly Instructions

PNEG-1785

NCHT “X” Series Ladders

57

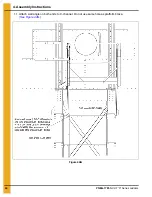

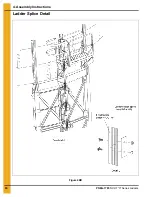

8. Attach wall angle on both ends to C-channel.

Figure 4BA

Summary of Contents for NCHT X Series

Page 1: ...PNEG 1785 NCHT X Series Ladders Assembly Instructions PNEG 1785 Date 01 27 11 ...

Page 2: ...2 PNEG 1785 NCHT X Series Ladders ...

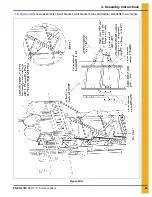

Page 49: ...4 Assembly Instructions PNEG 1785 NCHT X Series Ladders 49 Ladder Splice Detail Figure 4AS ...

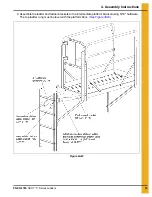

Page 60: ...4 Assembly Instructions 60 PNEG 1785 NCHT X Series Ladders Ladder Splice Detail Figure 4BD ...