GSK980MDc Milling CNC System User Manual

104

I Programming

B – Radius of arc, when a negative value is specified, it is major arc.

(I_ J_) – The circle center and radius are calculated by I or J when the R value is not

specified.

C – Number of punching

F – Cutting feedrate

Related parameter

:

status parameter

№

.0582

:

RPTK=1: hole positioning of continuous drilling is executed by cutting path (G01).

0: hole positioning of continuous drilling is executed by rapid traverse path (G00).

BRCH =1

:

return plane of continuous drilling is selected by G98,G99

=0

:

return plane of continuous drilling is selected by G99

For example:

G91 G142 G81 X100 R50 Z-50 C4

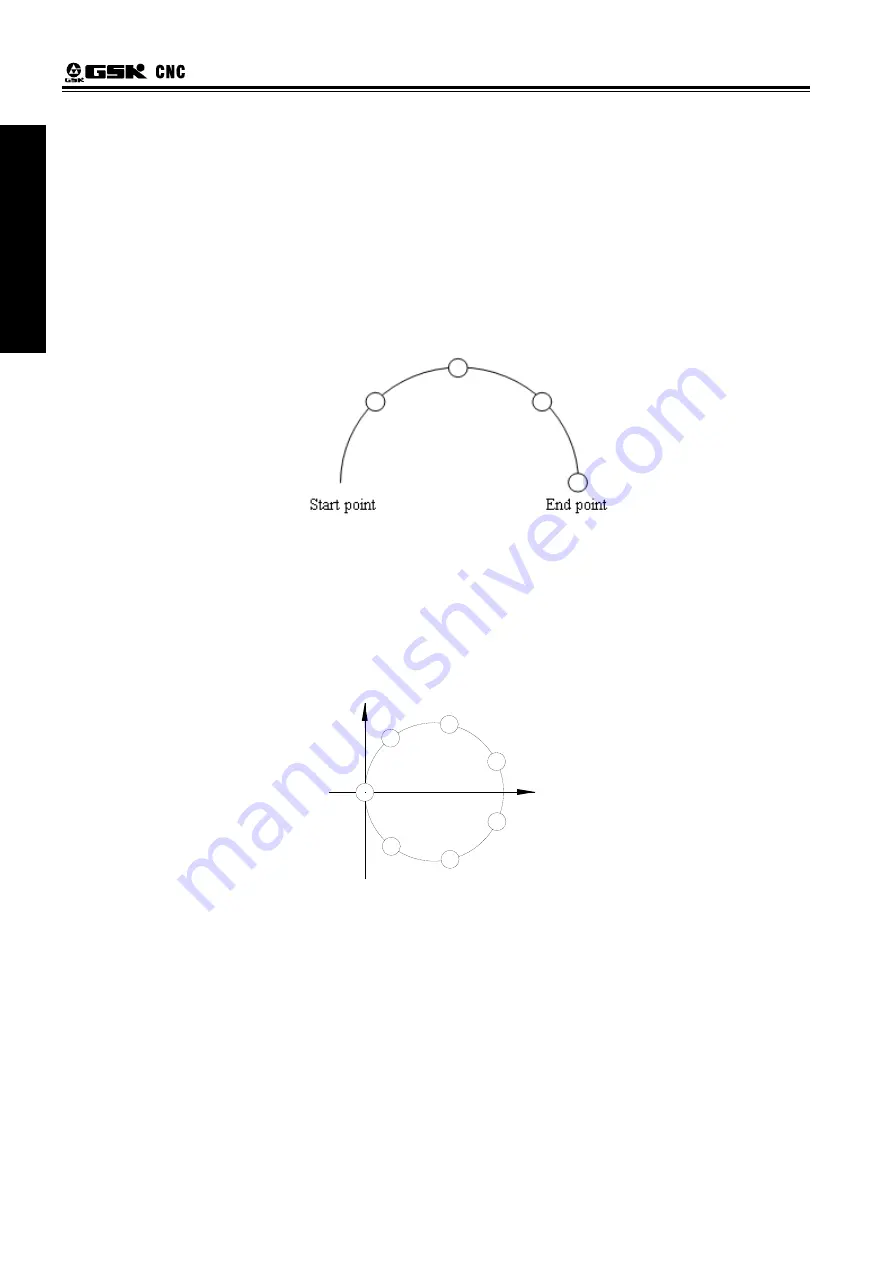

Example 2

:

when drilling 7 holes in full circle, the start points and end points are coordinate origins, and the

radius is 50, hole depth is 50.

O0001

;

G00 G90 X0 Y0 Z0 G17

;

G98 G142 G82 I50 J0 R-10 Z-50 C7 F3000

;

M30

;

%

1

2

3

4

5

6

7

Note 1:When starting point and end point are the same one in the continuous drilling and I, J are used to program,

the full-circle drilling is executed.

Note 2: Canned cycle G110, G111, G112, G113, G114, G115, G134, G135, G136, G137, G138, G139 has no continuous

drilling function.

Note 3: The maximum drilling number C is 9999; the negative value is processed as absolute value; the decimals are

rounded.

Note 4

:

When C is not specified or equals to 0, it reaches the end point directly and no drilling will be performed.

3.24.4 Cautions for Canned Cycle

(1) The spindle should be rotated (The M code should be correctly specified, or, the alarm will be

generated, the G74 by M04, G84 by M03) by using the miscellaneous function (M code) before the canned

cycle is executed.

(2) Specifying any command of the X, Y, Z and R data, the hole machining can be performed in the

canned cycle of G73~G89. If neither data is contained in the block, the hole machining is not performed

Summary of Contents for 980MDc

Page 19: ...GSK980MDc Milling CNC User Manual XVIII ...

Page 20: ...1 I Programming Programming Ⅰ ...

Page 21: ...GSK980MDc Milling CNC System User Manual 2 I Programming ...

Page 139: ...GSK980MDc Milling CNC System User Manual 120 I Programming ...

Page 191: ...GSK980MDc Milling CNC System User Manual 172 I Programming ...

Page 192: ...173 Ⅱ Operation Ⅱ Operation ...

Page 193: ...GSK980MDc Milling CNC System User Manual 174 Ⅱ Operation ...

Page 200: ...Chapter 1 Operation Mode and Display 181 Ⅱ Operation ...

Page 201: ...GSK980MDc Milling CNC System User Manual 182 Ⅱ Operation ...

Page 249: ...GSK980MDc Milling CNC System User Manual 230 Ⅱ Operation ...

Page 253: ...GSK980MDc Milling CNC System User Manual 234 Ⅱ Operation ...

Page 259: ...GSK980MDc Milling CNC System User Manual 240 Ⅱ Operation ...

Page 265: ...GSK980MDc Milling CNC System User Manual 246 Ⅱ Operation ...

Page 293: ...GSK980MDc Milling CNC System User Manual 274 Ⅱ Operation ...

Page 295: ...GSK980MDc Milling CNC System User Manual 276 Ⅱ Operation ...

Page 319: ...GSK980MDc Milling CNC System User Manual 300 Ⅱ Operation ...

Page 320: ...301 Ⅲ Installation Ⅲ Installation ...

Page 321: ...GSK980MDc Milling CNC System User Manual 302 Ⅲ Installation ...

Page 345: ...GSK980MDc Milling CNC System User Manual 326 Ⅲ Installation ...

Page 391: ...GSK980MDc Milling CNC System User Manual 372 Ⅲ Installation ...

Page 392: ...Appendix 373 Appendix Appendix ...

Page 393: ...GSK980MDc Milling CNC System User Manual 374 Appendix ...

Page 394: ...Appendix 375 Appendix Appendix 1 Outline Dimension of GSK980MDc L N ...