Chapter 2 Interface Signals

311

Ⅲ

Inst

allation

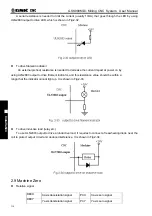

2.3.5 SVC Signal Explanation

The analog spindle interface SVC can output 0~10V voltage, its interior signal circuit is shown in Fig.

2-17:

2.3.6 Explanations for ALM5(X5.3)

When the 5

th

axis is valid (namely, it is set to linear axis or rotary axis), this signal is taken as alarm signal of

the 5

th

axis. Level of alarm signal is set by NO.009 ALM5

;

When the 5

th

axis is invalid, the signal is taken as alarm signal of common converter or gear spindle.

F35.0 is 1 in the alarm.

When the 5

th

axis is invalid and ALM5 (X5.3) pin signal is unused, NO.009 is set to 0;

When the 5

th

axis is invalid and ALM5 (X5.3) pin signal is taken as the alarm signal, the Level is set by

NO.009 ALM5;

ALM5

:

0

:

when it is connected with 0V, alarm occurs;

1

:

when it is not connected with 0V, alarm occurs.

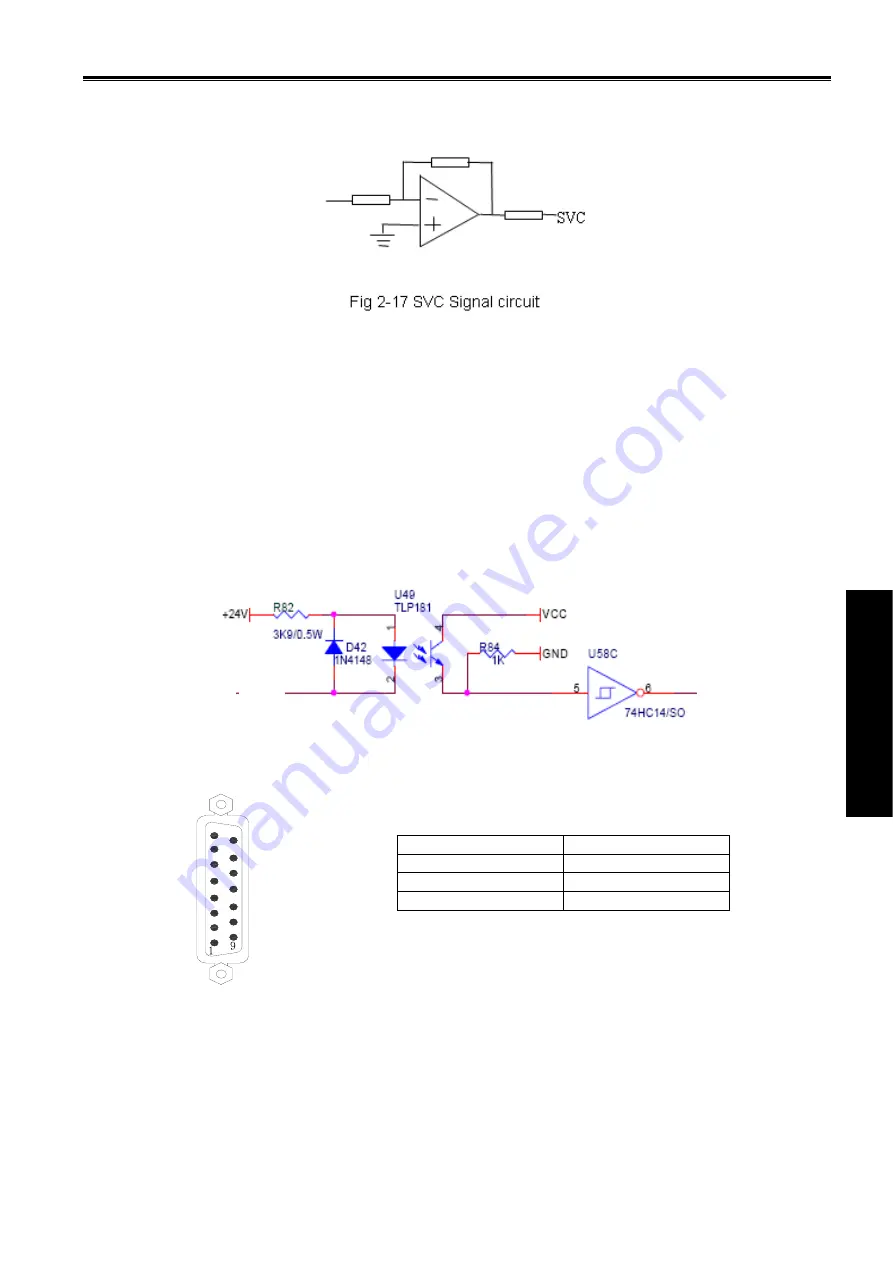

2.4 Connection to Spindle Encoder

2.4.1 Spindle Encoder Interface Definition

2.4.2 Signal Explanation

PZO-/PZO+, PBO-/PBO+, PAO-/PAO+ are the encoder Z, B, A phase differential input signals

respectively, which are received by 26LS32; MPB-/MPB+, MPA-/MPA+ are normal square wave of phase

shift 90°with the maximum signal frequency less than 1MHz; the encoder pulses for GSK980MDc are set

by data parameter No.3720, whose range is from 0 to 5000.

Its interior connection circuit is shown in Fig. 2-19:

(

n=A, B, Z

)

ALMn

Name Explanation

PAO-/PAO+

Encode A phase pulse

PBO-/PBO+

Encode B phase pulse

PZO-/PZO+

Encode Z phase pulse

Fig.2-18 CN21 Encode interface

(DB15 male socket)

8

:

PAO+

7

:

PAO-

6

:

PBO+

5

:

PBO-

4

:

PZO+

3

:

PZO-

2

:

1

:

15

:

GND

14

:

GND

13

:

VCC

12

:

VCC

11

:

GND

10

:

9

:

Summary of Contents for 980MDc

Page 19: ...GSK980MDc Milling CNC User Manual XVIII ...

Page 20: ...1 I Programming Programming Ⅰ ...

Page 21: ...GSK980MDc Milling CNC System User Manual 2 I Programming ...

Page 139: ...GSK980MDc Milling CNC System User Manual 120 I Programming ...

Page 191: ...GSK980MDc Milling CNC System User Manual 172 I Programming ...

Page 192: ...173 Ⅱ Operation Ⅱ Operation ...

Page 193: ...GSK980MDc Milling CNC System User Manual 174 Ⅱ Operation ...

Page 200: ...Chapter 1 Operation Mode and Display 181 Ⅱ Operation ...

Page 201: ...GSK980MDc Milling CNC System User Manual 182 Ⅱ Operation ...

Page 249: ...GSK980MDc Milling CNC System User Manual 230 Ⅱ Operation ...

Page 253: ...GSK980MDc Milling CNC System User Manual 234 Ⅱ Operation ...

Page 259: ...GSK980MDc Milling CNC System User Manual 240 Ⅱ Operation ...

Page 265: ...GSK980MDc Milling CNC System User Manual 246 Ⅱ Operation ...

Page 293: ...GSK980MDc Milling CNC System User Manual 274 Ⅱ Operation ...

Page 295: ...GSK980MDc Milling CNC System User Manual 276 Ⅱ Operation ...

Page 319: ...GSK980MDc Milling CNC System User Manual 300 Ⅱ Operation ...

Page 320: ...301 Ⅲ Installation Ⅲ Installation ...

Page 321: ...GSK980MDc Milling CNC System User Manual 302 Ⅲ Installation ...

Page 345: ...GSK980MDc Milling CNC System User Manual 326 Ⅲ Installation ...

Page 391: ...GSK980MDc Milling CNC System User Manual 372 Ⅲ Installation ...

Page 392: ...Appendix 373 Appendix Appendix ...

Page 393: ...GSK980MDc Milling CNC System User Manual 374 Appendix ...

Page 394: ...Appendix 375 Appendix Appendix 1 Outline Dimension of GSK980MDc L N ...