GSK988T Turning CNC System User Manual

92

Ⅰ

Programming

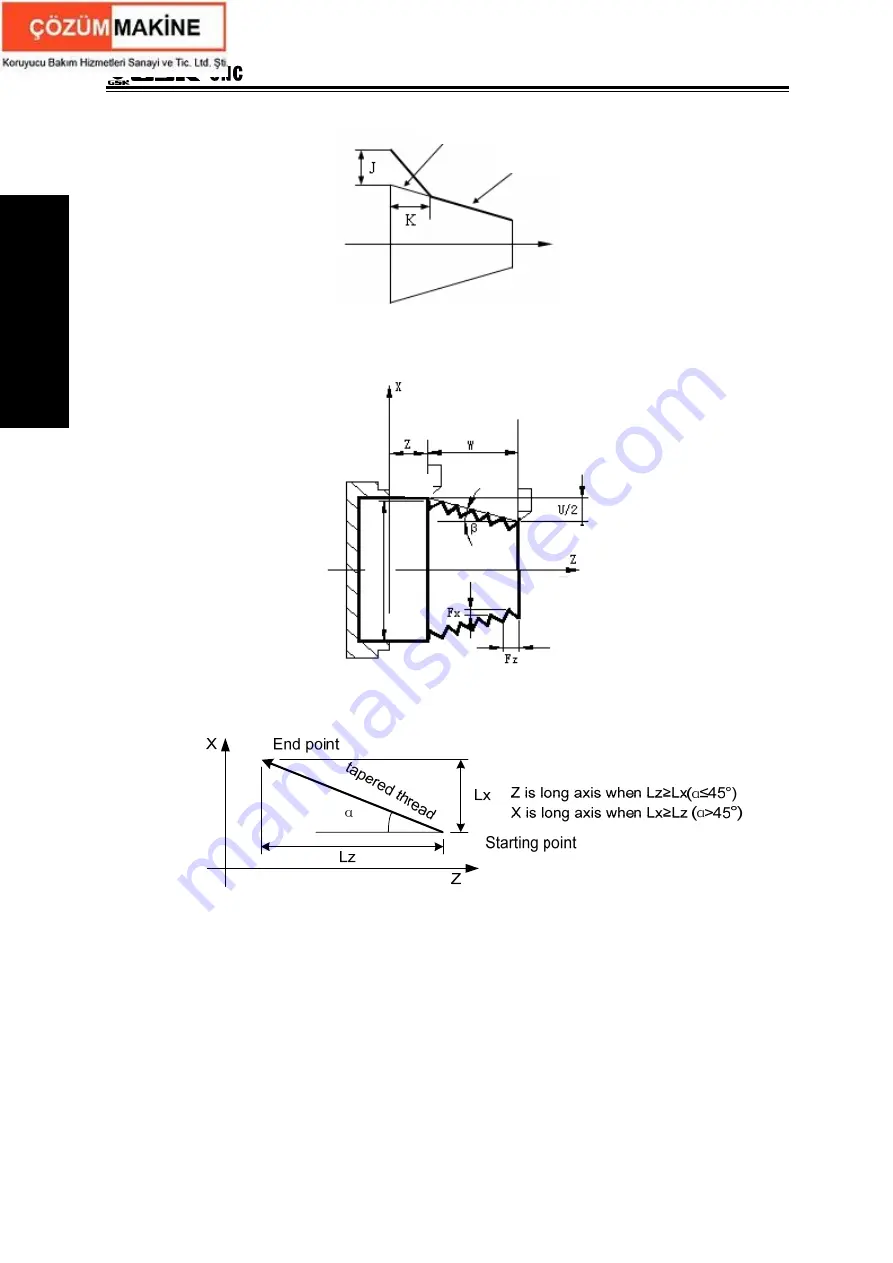

Fig. 2-54 thread run-out

Command path:

Difference between long axis and short axis:

Fig.2-56 long axis, short axis

Note 1: When the thread run-out, the short axis executes the thread run-out at the rapid speed, and the

long does it at the current thread cutting speed.

Note 2: J, K are modal. The thread run-out is previous J, K value when they are omitted in the next block in

continuous thread cutting. Their mode are cancelled when no thread cutting are executed;

Note 3: There is no thread run-out when J, or J, K are omitted; K=J is the thread run-out value when K is

omitted;

Note 4: There is no thread run-out when J=0 or J=0, K=0;

Note 5: The thread run-out value J=K when J

≠

0,K=0;

Note 6: There is no thread run-out when J=0 or K

≠

0;

Note 7: If the current block is for thread and the next block is the same, the system does not test the

spindle encoder signal per rev at starting the next block to execute the direct thread cutting, which

function is called as continuous thread machining;

Note 8: After the feed hold is executed, the system displays “Pause” and the thread cutting continuously

Fig.2-55 G32 path

Programmed end point of thread

Tool path

End

point

Current point

Summary of Contents for 988T

Page 6: ...GSK988T Turning CNC System User Manual VI ...

Page 14: ...GSK988T Turning CNC System User Manual XIV ...

Page 15: ...Chapter 1 Programming Fundamentals 1 Ⅰ Programming Ⅰ PROGRAMMING ...

Page 16: ...GSK988T Turning CNC System User Manual 2 Ⅰ Programming ...

Page 194: ...GSK988T Turning CNC System User Manual 180 Ⅰ Programming ...

Page 195: ...Chapter Ⅰ Overview 181 Ⅱ Operation Ⅱ OPERATION ...

Page 196: ...GSK988T Turning CNC System User Manual 182 Ⅱ Operation ...

Page 217: ...Chapter Ⅲ Windows 203 Ⅱ Operation ...

Page 267: ...Chapter Ⅲ Windows 253 Ⅱ Operation Fig 3 51 Fig 3 52 ...