GSK988T Turning CNC System User Manual

152

Ⅰ

Programming

4.1.2 Imaginary tool nose direction

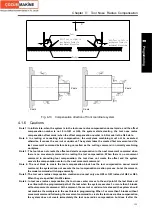

Suppose that it is generally difficult to set the tool nose radius center on the initial position as Fig.

4-3; suppose that it is easily set the tool nose on it as Fig. 4-4; The tool nose radius can be omitted in

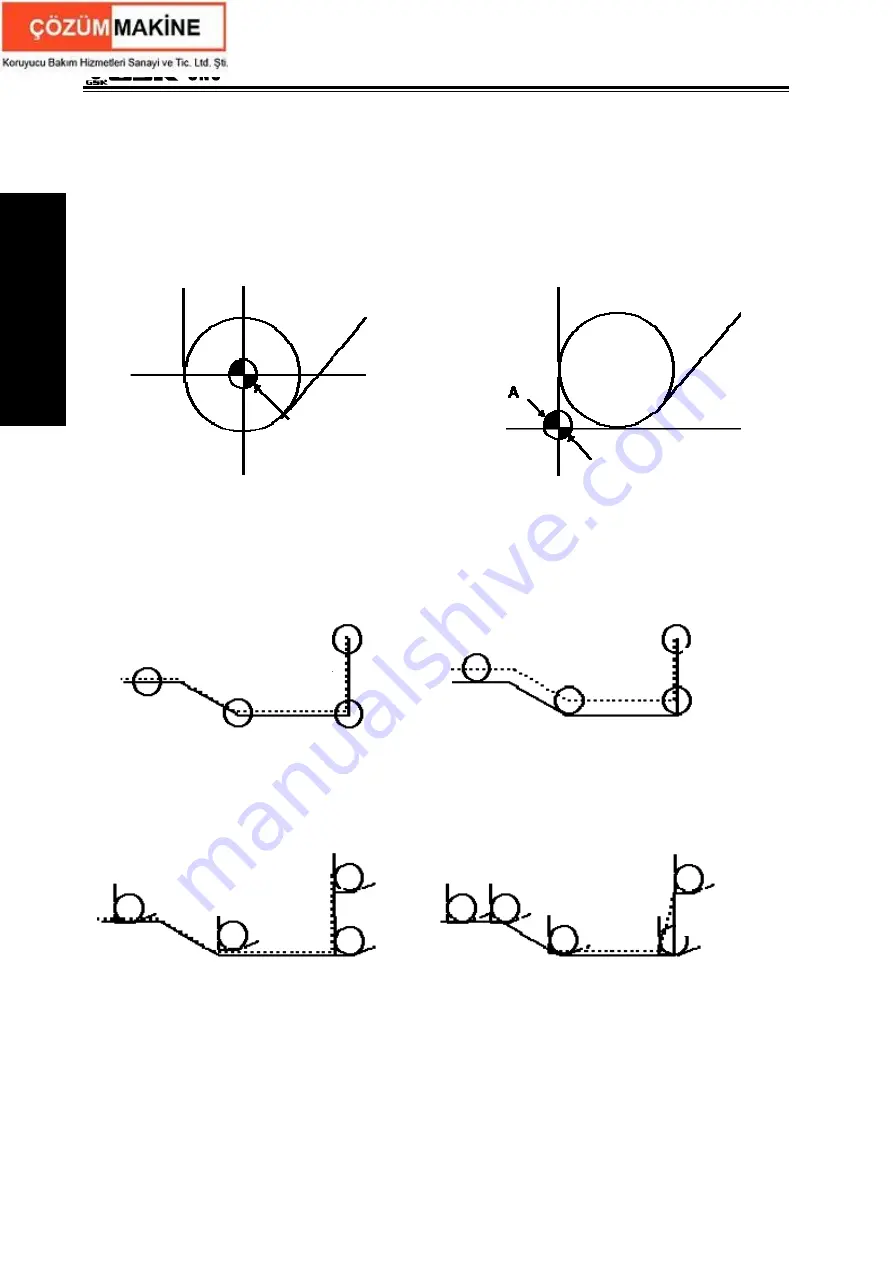

programming. Fig. 4-5 and Fig.4-6 correspond separately to the tool paths of tool nose center

programming and imaginary tool nose programming when tool nose radius is executed or not.

Fig. 4-5 Tool path in tool nose center programming

The tool is supposed to one point in programming but the actual cutting blade is not one ideal

point owing to machining technology. Because the cutting blade is not one point but one circular,

machining error is caused which can be deleted by tool nose circular radius compensation. In actual

machining, suppose that there are different position relationship between tool nose point and tool

nose circular center point, and so it must create correct its direction of imaginary tool nose.

From tool nose center to imaginary tool nose, set imaginary tool nose numbers according to tool

Tool nose path is the same as programming Finishing when using tool nose radius

path without using tool nose radius compensation compensation

Tool nose path is the same as programming Finishing when using tool

path without using tool nose radius compensation

nose radius compensation

Fig. 4-6 Tool path in imaginary tool nose programming

Fig. 4-4

Starting point

Starting point

Programming with tool nose center

Programming with imaginary tool nose

Programmed path

Programmed path

Tool nose

center path

Start compensation

Tool nose

center path

Programmed path

Start compensation

Imaginary tool

nose path

Programmed path

Imaginary tool

nose path

Fig. 4-3

Summary of Contents for 988T

Page 6: ...GSK988T Turning CNC System User Manual VI ...

Page 14: ...GSK988T Turning CNC System User Manual XIV ...

Page 15: ...Chapter 1 Programming Fundamentals 1 Ⅰ Programming Ⅰ PROGRAMMING ...

Page 16: ...GSK988T Turning CNC System User Manual 2 Ⅰ Programming ...

Page 194: ...GSK988T Turning CNC System User Manual 180 Ⅰ Programming ...

Page 195: ...Chapter Ⅰ Overview 181 Ⅱ Operation Ⅱ OPERATION ...

Page 196: ...GSK988T Turning CNC System User Manual 182 Ⅱ Operation ...

Page 217: ...Chapter Ⅲ Windows 203 Ⅱ Operation ...

Page 267: ...Chapter Ⅲ Windows 253 Ⅱ Operation Fig 3 51 Fig 3 52 ...