Chapter

Ⅳ

Tool Nose Radius Compensation

161

Ⅰ

Programming

G01 Z0 F300; (Start cutting)

X16;

Z-14 F200;

G02 X28 W-6 R6;

G01 W-7;

X32;

Z-35;

G40 G00 X90 Z40; (Cancel tool nose radius compensation)

G00 X100 Z50 T0100;

M30;

4.2 Tool Nose Radius Compensation Offset Path

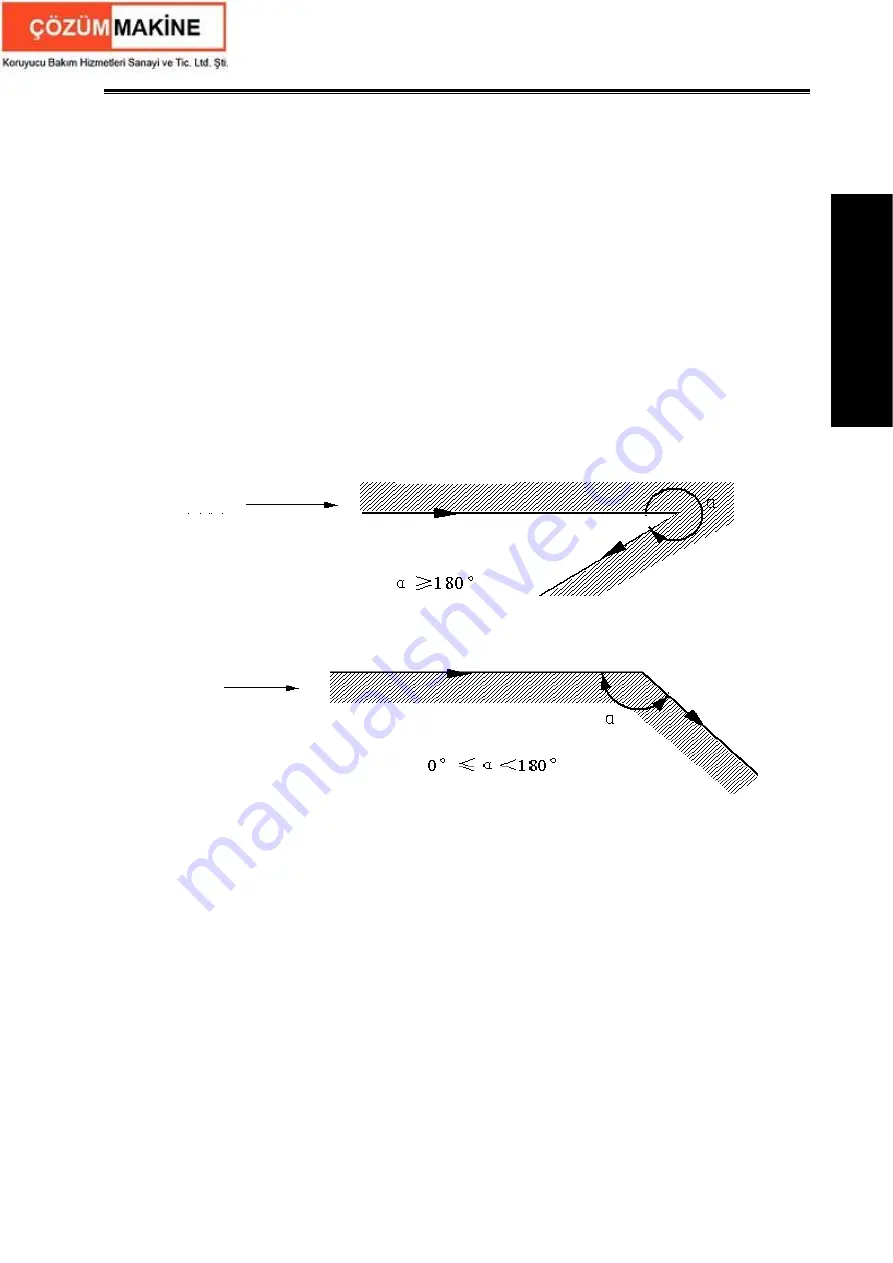

4.2.1 Inner and outer side

Inside

is defined that an angle at intersection of two motion blocks is more than or equal to 180°;

Outside

is 0~180°.

Fig. 4-15

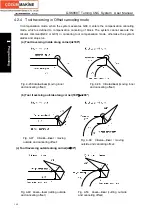

4.2.2 Tool traversing when starting tool

3 steps to execute tool nose radius compensation: tool compensation creation, tool

compensation execution and tool compensation canceling.

Tool traverse is called tool compensation creation (starting tool) from offset canceling to G41 or

G42 execution.

Note: Meanings of S, L, C in the following figures are as follows:

S

――

Stop point of single block; L

――

linear; C

――

circular, R

――

tool radius compensation

;

α――

angle between two blocks.

Workpiece side

Inner

Programmed path

Outer

Programmed path

Workpiece side

Summary of Contents for 988T

Page 6: ...GSK988T Turning CNC System User Manual VI ...

Page 14: ...GSK988T Turning CNC System User Manual XIV ...

Page 15: ...Chapter 1 Programming Fundamentals 1 Ⅰ Programming Ⅰ PROGRAMMING ...

Page 16: ...GSK988T Turning CNC System User Manual 2 Ⅰ Programming ...

Page 194: ...GSK988T Turning CNC System User Manual 180 Ⅰ Programming ...

Page 195: ...Chapter Ⅰ Overview 181 Ⅱ Operation Ⅱ OPERATION ...

Page 196: ...GSK988T Turning CNC System User Manual 182 Ⅱ Operation ...

Page 217: ...Chapter Ⅲ Windows 203 Ⅱ Operation ...

Page 267: ...Chapter Ⅲ Windows 253 Ⅱ Operation Fig 3 51 Fig 3 52 ...