Chapter

Ⅺ

Parameters

339

Ⅱ

Operation

11.13 Parameters Related to the Spindle Control

#7 #6 #5 #4 #3 #2 #1 #0

3700

NRF

『

Modification authority

』

: Equipment

『

Default Setting

』

: 0000 0000

#1 NRF The first move command(G00) after the spindle is switched to Cs axis

performs

0:Positioning after returning to the reference postion

1:Normal positioning

#7 #6 #5 #4 #3 #2 #1 #0

3705

EVS

#4 EVS When the spindle control function is used, S codes and SF are (spindle analog

output or spindle serial output)

0: Not output for an S command

1: Output for an S command

#7 #6 #5 #4 #3 #2 #1 #0

3706

PG2

PG1

『

Default Setting

』

: 0000 0000

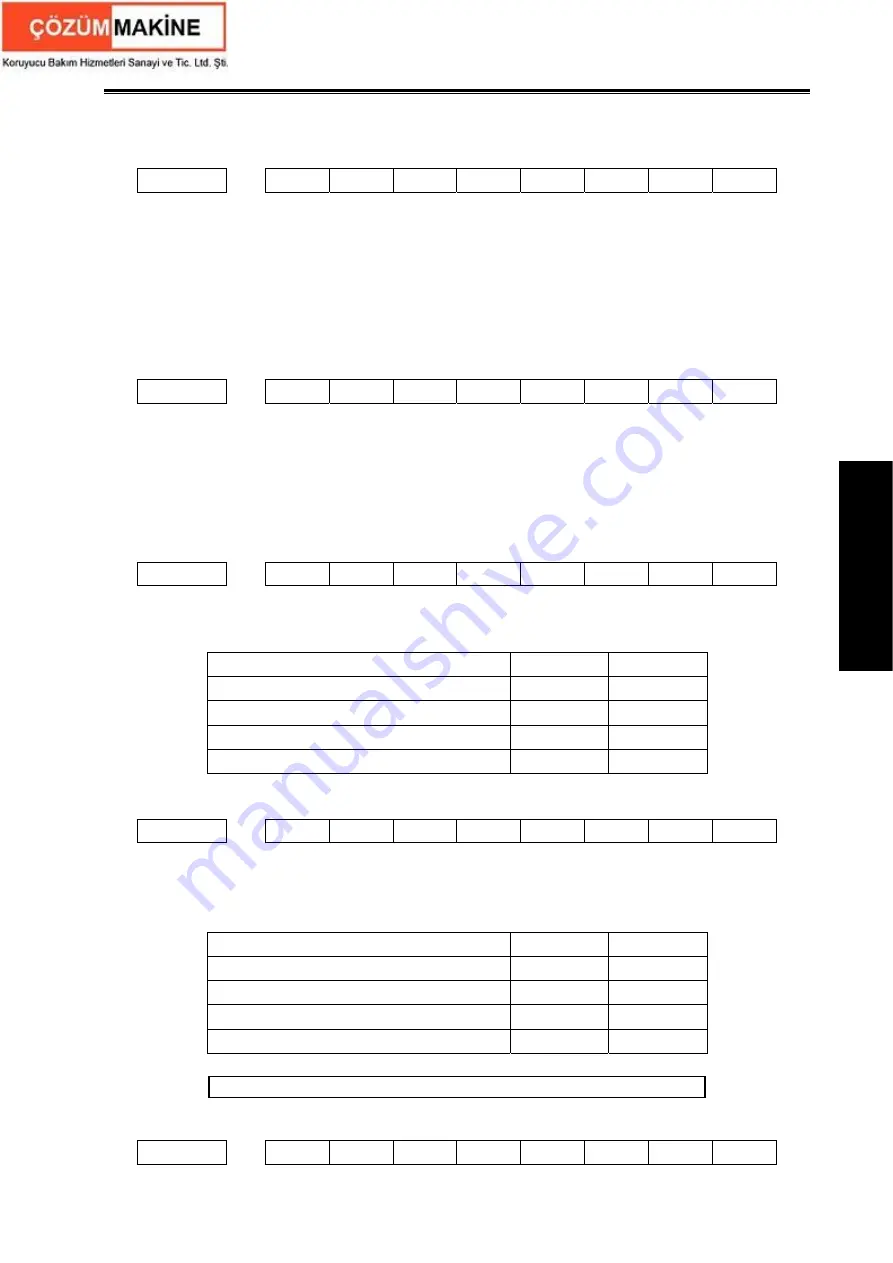

#0, #1 PG2 and PG1 Gear ratio between the spindle and the position encoder.

Gear ratio=spindle speed/position encoder speed

Gear ratio

PG2

PG1

×1 0

0

×2 0

1

×4 1

0

×8 1

1

#7 #6 #5 #4 #3 #2 #1 #0

3707

P22

P21

『

Default Setting

』

: 0000 0000

#0, #1 P22 and P21 Gear ratio between the spindle and the second position encoder.

Gear ratio= spindle speed/position encoder speed

Gear ratio

P22

P21

×1 0

0

×2 0

1

×4 1

0

×8 1

1

Note: The parameter is valid only when multi-spindle control.

#7 #6 #5 #4 #3 #2 #1 #0

3708

TSO

SAT

SAR

Summary of Contents for 988T

Page 6: ...GSK988T Turning CNC System User Manual VI ...

Page 14: ...GSK988T Turning CNC System User Manual XIV ...

Page 15: ...Chapter 1 Programming Fundamentals 1 Ⅰ Programming Ⅰ PROGRAMMING ...

Page 16: ...GSK988T Turning CNC System User Manual 2 Ⅰ Programming ...

Page 194: ...GSK988T Turning CNC System User Manual 180 Ⅰ Programming ...

Page 195: ...Chapter Ⅰ Overview 181 Ⅱ Operation Ⅱ OPERATION ...

Page 196: ...GSK988T Turning CNC System User Manual 182 Ⅱ Operation ...

Page 217: ...Chapter Ⅲ Windows 203 Ⅱ Operation ...

Page 267: ...Chapter Ⅲ Windows 253 Ⅱ Operation Fig 3 51 Fig 3 52 ...