Chapter 6 Specification of Parameters

GK600 User Manual

- 204 -

F0-00

PID setting

Range: 0~5

Factory default: 0

Select the setting source of PID control.

0: F0-01 digital setting

1:AI1

2:AI2

3: EAI (on IO option board)

4: X6/DI pulse input

5: Communication

F0-01

PID digital setting

Range: 0.0%~100.0%

Factory default:

50.0%

When F0-00 is set to 0, this parameter value is taken as the set value of PID.

F0-02

PID feedback

Range: 0~8

Factory default: 0

Select the feedback source of PID control.

0:AI1

1:AI2

2: EAI (on IO option board)

3:AI1+AI2

4:AI1-AI2

5:max

{

AI1

,

AI2

}

6:min

{

AI1

,

AI2

}

7: X6/DI pulse input

8: Communication

F0-03

PID adjustment

Range: 00~11

Factory default: 11

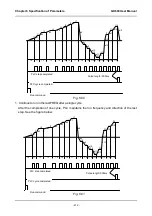

Ones place: output frequency

0: Must be the same direction as the set run direction

When PID frequency output direction is opposite to the rotary set direction, PID output is 0.

1: Opposite direction allowed

PID frequency output direction can be opposite to the rotary set direction, and PID output

performs normally.

Tens place: integration selection

0: Integral continued when frequency attains upper/lower frequency

Under PID control, when output frequency attains upper/lower limit of frequency or

parameter value of F0-23 (maximum frequency if it is opposite to the rotary set direction), PID

integral continues. This mode requires longer time of quitting saturation.

1: Integral stopped when frequency attains upper/lower limit

Under PID control, when output frequency attains upper/lower limit of frequency or

parameter value of F0-23 (maximum frequency if it is opposite to the rotary set direction), PID