1

IMPORTANT SAFETY INSTRUCTIONS

Because automatic gate openers produce high levels of force, consumers need to know the potential hazards associated with

improperly designed, installed, and maintained automated gate opener systems.

Keep in mind that the gate opener is just

one component of the total gate operating system

. Each component must work in unison to provide the consumer with

convenience, security, and safety.

This manual contains various safety precautions and warnings for the consumer. Because there are many possible

applications of the gate opener, the safety precautions and warnings contained in this manual cannot be completely

exhaustive in nature. They do, however, provide an overview of the safe design, installation, and use of this product.

CAREFULLY READ AND FOLLOW ALL SAFETY PRECAUTIONS, WARNINGS, AND INSTALLATION

INSTRUCTIONS TO ENSURE THE SAFE SYSTEM DESIGN, INSTALLATION, AND USE OF THIS PRODUCT.

Precautions and warnings in this manual are identified with this

warning symbol. The symbol identifies conditions

that can result in damage to the opener or its components, serious injury, or death.

Because GTO/PRO automatic gate openers are

only

part

of the total gate operating system, it is the responsibility of

the consumer to ensure that the total system is safe for its intended use.

©2005 GTO, Inc.

R

2500INST

rev - 0

3/02/05

Installation Manual for the

WARNING!

This equipment is similar to other gate or door equipment and meets or exceeds

Underwriters Laboratory Standard 325 (UL 325). However, gate equipment has

hazards associated with its use and therefore by installing this product the

installer and user accept full responsibility for following and noting the installation

and safety instructions. Failure to follow installation and safety instructions can

result in hazards developing due to improper assembly. You agree to properly

install this product and that if you fail to do so GTO, Inc. shall in no event be

liable for direct, indirect, incidental, special or consequential damages or loss of

profits whether based in contract tort or any other legal theory during the course

of the warranty or at any time thereafter. The installer and/or user agree to

assume responsibility for all liability and use of this product releasing GTO, Inc.

from any and all liability. If you are not in agreement with this disclaimer or do

not feel capable of properly following all installation and safety instructions you

may return this product for full replacement value.

READ ALL INSTRUCTIONS CAREFULLY AND COMPLETELY before

attempting to install and use this automatic gate opener. This gate opener

produces a high level of force. Stay clear of the unit while it is operating and

exercise caution at all times.

All automatic gate openers are intended for use on vehicular gates only.

This product meets and exceeds the requirements of UL 325, the standard which regulates gate opener safety,

as established and made effective March 1, 2000, by Underwriters Laboratories Inc.

GTO/PRO • 3121 Hartsfield Road • Tallahassee, Florida, USA 32303

Telephone GTO/PRO Sales: 1-800-543-GATE (4283) or (850) 575-0176 • Fax (850) 575-8912

or GTO/PRO Technical Service: 1-800-543-1236 or (850) 575-4144 • Fax (850)575-8950

www.gtopro.com

Automatic Gate Operator

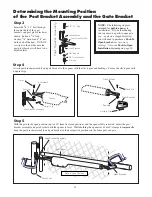

NOTE:

Substitute a

Pin Lock

for the clevis pin on the front

mount of the gate opener to prevent unauthorized removal of the

opener from the gate (

see Accessory Catalog).

Disconnecting the operator

1.

Turn operator power switch

OFF

.

2.

Remove hairpin clip, clevis pin, and bushing

from the front mounting point.

3.

Remove the operator from the mount.

The gate can be opened and closed manually

when the operator is disconnected.

To Manually Open and Close the

Gate, Follow the Procedure Below:

CAUTION: The gate will move freely and uncontrolled when the gate operator is

removed from the gate. ONLY disconnect the operator when the operator power switch

is OFF and the gate is NOT moving.

Clevis Pin

Hairpin Clip

Gate Bracket

Front or Rear Mount

Bushing

CAUTION:

Because the GTO/PRO gate operator is

battery powered, disconnect the

operator

ONLY when the

power switch on the

operator

is turned OFF. Unplugging

the transformer does not turn power to the

operator

OFF.

IMPORTANT:

NEVER allow operator arm to hang by

the front mount - it will break from the arm weight.