32

Connecting Accessories

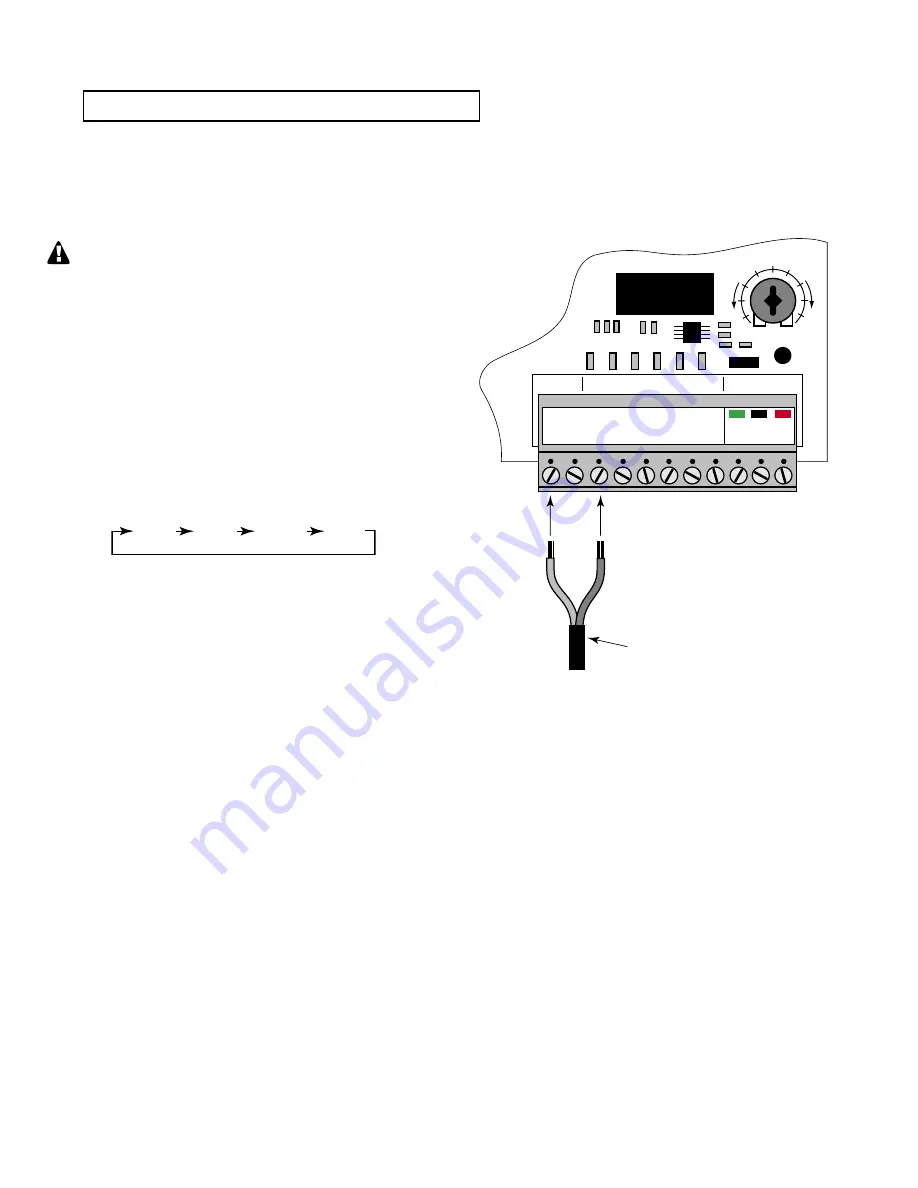

The GTO/PRO® 3000/3200 can accept NORMALLY OPEN CONTACT accessories, such as; Push Button Entry De-

vices and Key Pads.

Refer to the sensor manufacturer’s instructions for information about installing these devices on a vehicular gate.

Make sure the power to the operator is turned

off before connecting safety device wiring to the

terminal blocks. Unplugging the transformer

does not turn power to the operator OFF.

Accessory Input Connection:

Connect one of the accessory wires to the

COMMON (COM)

terminal and the other to the

CYCLE CLOSE

terminal on the

GTO/PRO® 3000/3200 control board.

Each activation of the accessory will cause the

gate to cycle as follows:

OPEN STOP CLOSE STOP

If not connecting accessories skip to next section.

Wire from Accessory

(push button, key pad, etc.)

STALL FORCE

MI

N

MA

X

GRN

BLK

RED

RECEIVER

COM

COM

CYCLE

CLOSE

SAFETY

EXI

T

OPEN

SHADOW

LOOP

CLOSE

EDGE

OPEN

EDGE

J11

J8

J12

The output relay provides N/O and N/C contact. N/O contact

functions only when gate is moving. N/C contact functions only

when gate is at rest. Relay can switch up to 36 volts A/C or D/C

and can be used for strobe type warning lights, to turn on safety

beams, etc.

Output Relay