7

IMPORTANT SAFETY INSTRUCTIONS

These warning labels should be found

at the locations specified below.

If any of them are missing,

immediately contact GTO for

replacements.

!

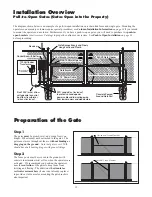

Warning signs (4 enclosed) to be installed on each side

of the gate (3–5 feet above the bottom of the gate).

Maximum Gate: 1000 lb. (453.5 kg); 20 ft. (6.1 m)

Voltage: 12 Vdc; Frequency: 0 Hz; Power: 60 W

Class I, II, III and IV Vehicular Swing Gate Operator.

Serial Number: XXXXXXXXXX

#xxxxxxx

Conforms to UL 325 STANDARDS

TO MANUALLY OPEN AND CLOSE THE GATE:

1. Turn control box power switch OFF.

2. Disconnect front or rear mount from gate bracket.

3. Pull operator away from front or real mounts.

DC SW-4000 SERIES

GTO, Inc.

Tallahassee, Florida USA

Disconnect operator ONLY when the control box power

switch is OFF and the gate is NOT moving.

L I S T E D

US

C

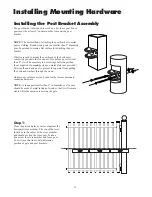

Product identification and manual operation instruction

label (1) installed on control box.

Logo and warning labels (2) installed on each side of master operator housing.

1. KEEP CLEAR! Gate may move at any time.

2. Do not allow children to operate gate or play in

gate area.

3. This gate is for vehicles only. Pedestrians must

use separate entrance.

WARNING

!

MOVING GATE

Can Cause Injury or Death

®

DC-SERIES

1-800-543-GATE (4283) • www.gtopro.com

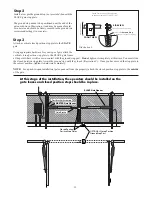

Logo and warning labels (2) installed on each side of slave operator housing.

1. KEEP CLEAR! Gate may move at any time.

2. Do not allow children to operate gate or play in

gate area.

3. This gate is for vehicles only. Pedestrians must

use separate entrance.

WARNING

!

MOVING GATE

Can Cause Injury or Death

1-800-543-GATE (4283) • www.gtopro.com

®

DC-SERIES