15

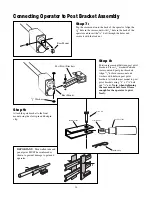

Step 10:

Open the gate to the desired position (at least 10º and no greater

than 110º). Position the operator so that the gate bracket just

rests against the gate. Check the clearance between the operator

and the gate. The operator should only make contact with the

gate at the gate bracket. However, there should not be too much

clearance between the operator and the gate, or the operator will

fully extend before it reaches the closed position. See illustra-

tion at right for examples of clearance.

Step 11:

Now align spacer and post pivot brackets hole with the

post bracket hole that provides the best clearance. Insert

the

1

/

2

" x 3

3

/

4

" bolt through holes in post bracket, post

pivot brackets and spacer. When tightening the

1

/

2

" nut,

leave it loose enough so that you can make adjustments

later.

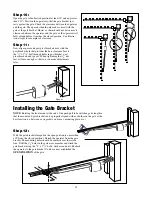

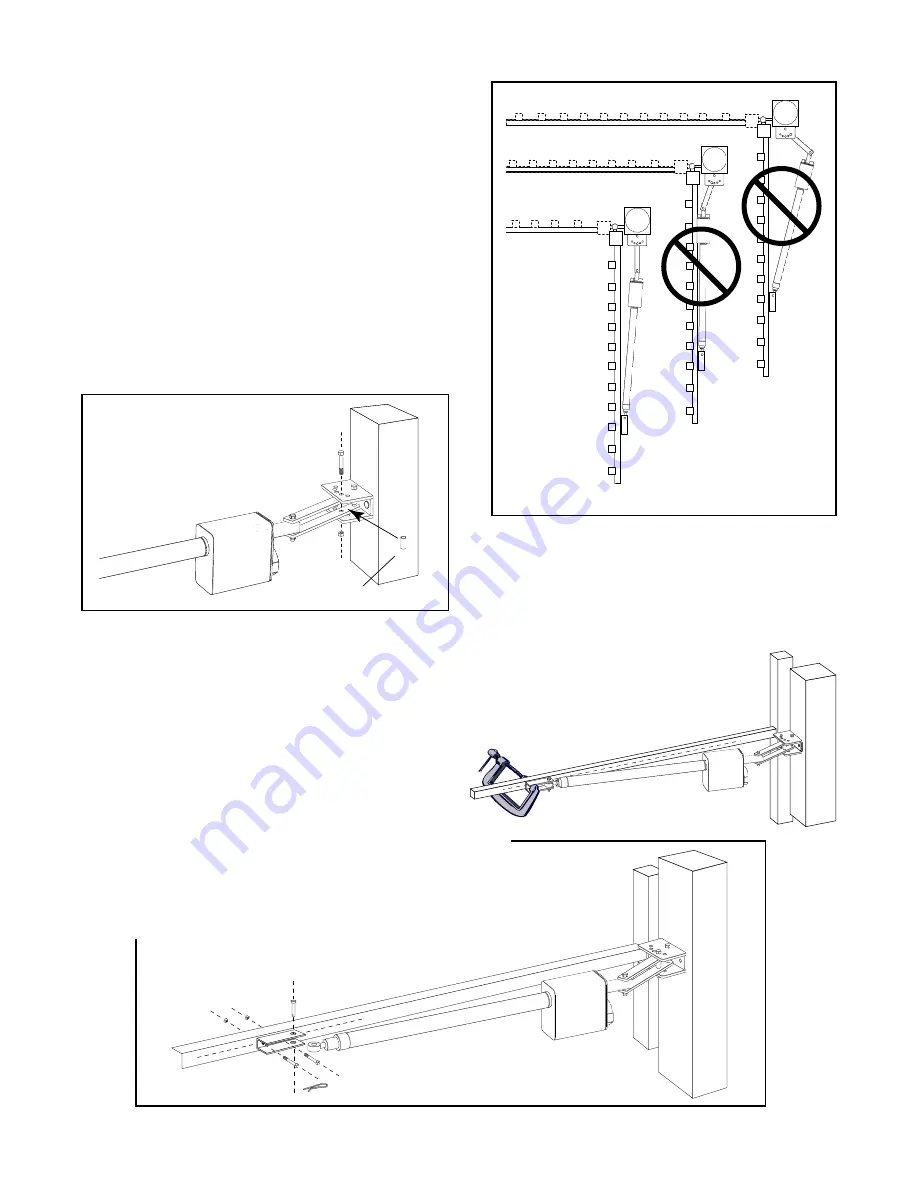

Installing the Gate Bracket

Spacer

Step 12:

With the gate bracket clamped in the open position (no more than

110

o

from the closed position). Detach the operator from the gate

bracket. The mounting holes should be centered over the scribe

line. Drill the

1

/

2

" holes in the gate cross member and attach the

gate bracket using the

1

/

2

" x 2

3

/

4

" bolts, washers and nuts. Reattach

the operator to the gate bracket. You have now established the

OPEN POSITION of the gate.

NOTE: Rotating the front mount at the end of the push-pull tube will change its length so

that the mount and gate bracket can be properly aligned with each other on the gate at the

best location (i.e. between or on pickets, on braces, mounting plate, etc.).