23

Setting the Closed Position Limit

for Pull to Open Applications

TURN CONTROL BOX ON

Your GTO/PRO® has two Limit Settings

)

OPEN Limit setting:

(Gate in the OPEN POSITION / the limit is FACTORY SET and NOT ADJUSTABLE) The open

limit setting is the fully open position.

2)

CLOSED Limit setting:

(Gate in the CLOSED POSITION) To achieve optimum closed position, you are required

to complete the following FOUR STEPS:

NOTE: Customer may need to adjust the stall force in order to set the limits.

Step 1

Confirm that the power switch is in the ON position and the gate

is in the OPEN POSITION.

Step 2

Activate your opener by pressing the entry transmitter button.

Your gate should now be moving from the fully open position

toward the closed position. Prepare to STOP the gate by pressing

the entry transmitter button again when the gate reaches the

desired closed position. This step may be repeated until desired

close position is achieved. Once the desired CLOSED position

has been achieved, proceed to step 3.

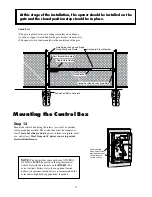

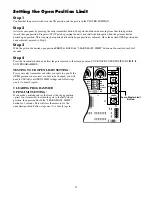

Step 3

With the gate in the desired closed position PRESS & HOLD

the “LEARN MAST LIMIT" button on the control board for 5

seconds or until buzzer sounds.

Step 4

Press the transmitter button and allow the gate to return to the

fully open position. YOUR GATE’S CLOSED POSITION LIMIT

IS NOW PROGRAMMED.

TESTING YOUR CLOSED LIMIT SETTING:

Press your entry transmitter and allow your gate to close. If the CLOSED position is not correct or needs to be changed, you

will need to CLEAR your CLOSED LIMIT settings and follow Steps -4 again.

CLEARING THE PROGRAMMED CLOSED LIMIT SETTING:

If you make a mistake and set the limit at the wrong position – press your transmitter to return the gate to the fully opened

position, then press and hold the "LEARN MAST LIMIT" button for 5 seconds. This will clear the memory for the closed

limit position. Follow Steps -4 again.

1

2

3

4

O

N

D

IP

STATUS

LEARN RMT

LEARN

MAST LIMIT

LEARN

SLV LIMIT

S3

S4

S2

ART OFF

G OFF

PULL

EN DLY.

OFF

OFF

ON

ON

PUSH

SIMULT.

ON

ON

120 MIN

MAX

CLOSE TIME

STALL FORCE

Learn Master Limit

Button