When valve clearance is correct, hold the pivot ball stud in place

with the allen wrench and tighten the rocker arm jam nut.

Tighten the jam nut to 174 in/lbs. torque. After tightening the jam

nut, recheck valve clearance to make sure it did not change.

• Install new valve cover gasket (Part number 0C2979).

• Re-attach the valve cover and torque to 4.8 to 5.5 ft. - lbs.

NOTE:

Start all four screws before tightening or you will not

be able to get all the screws in place. Make sure the valve

cover gasket is in place.

• Re-attach the spark plug wire to the spark plug.

• Repeat the process for the other cylinder.

STORAGE INSTRUCTIONS

This engine should be started at least once a month and run for

at least 10 minutes

. If this cannot be done and the

equipment must be stored for more than 30 days, use the

following guidelines to prepare it for storage.

WARNING:

Never store the engine with the fuel in

the tank indoors or in an enclosed or poorly ventilated

area. Fumes can reach an open flame, spark, or pilot

light as on a furnace, water heater, or clothes dryer

and ignite.

1. Run the engine for about five (5) minutes to warm it.

NOTE:

Alcohol-blended fuel, or “gasohol”, attracts moisture

which can lead to the separation and formation of acids during

storage. This acidic gas can damage internal engine parts.

Methanol, ethanol and grain alcohol all are forms of gasohol. If

you did use “gasohol,” drain the fuel tank, then run the engine

until it stops from lack of fuel.

WARNING:

Drain the fuel into approved container,

outdoors, away from open flame. Be sure the engine is

cool.

NOTE:

Using a fuel additive such as STA-BIL

®

fuel stabilizer,

or an equivalent, will prevent gum deposits from forming in the

engine’s fuel system.

2. While the engine is still warm, drain the oil from the

crankcase. Refill it with fresh oil. See

BEFORE

STARTING ENGINE

on Page 6 for oil

recommendations.

3. Remove spark plug and pour about 1/2 ounce (15ml) of

engine oil into the cylinder. Crank slowly to distribute oil.

CAUTION:

Avoid spray from the spark plug hole when

cranking the engine slowly.

4. Install the spark plug. Do not connect the spark plug wire.

5. Clean the dirt, oil and grease from the cylinder, cylinder

head, fins, blower housing, rotating screen and muffler area.

6. Close the fuel shut-off valve.

OTHER STORAGE TIPS

1. Do not store gasoline from one season to another.

2. Replace the gasoline can if it starts to rust. Rust and/or dirt

in gasoline can cause problems.

3. Store the equipment in a clean and dry area.

11

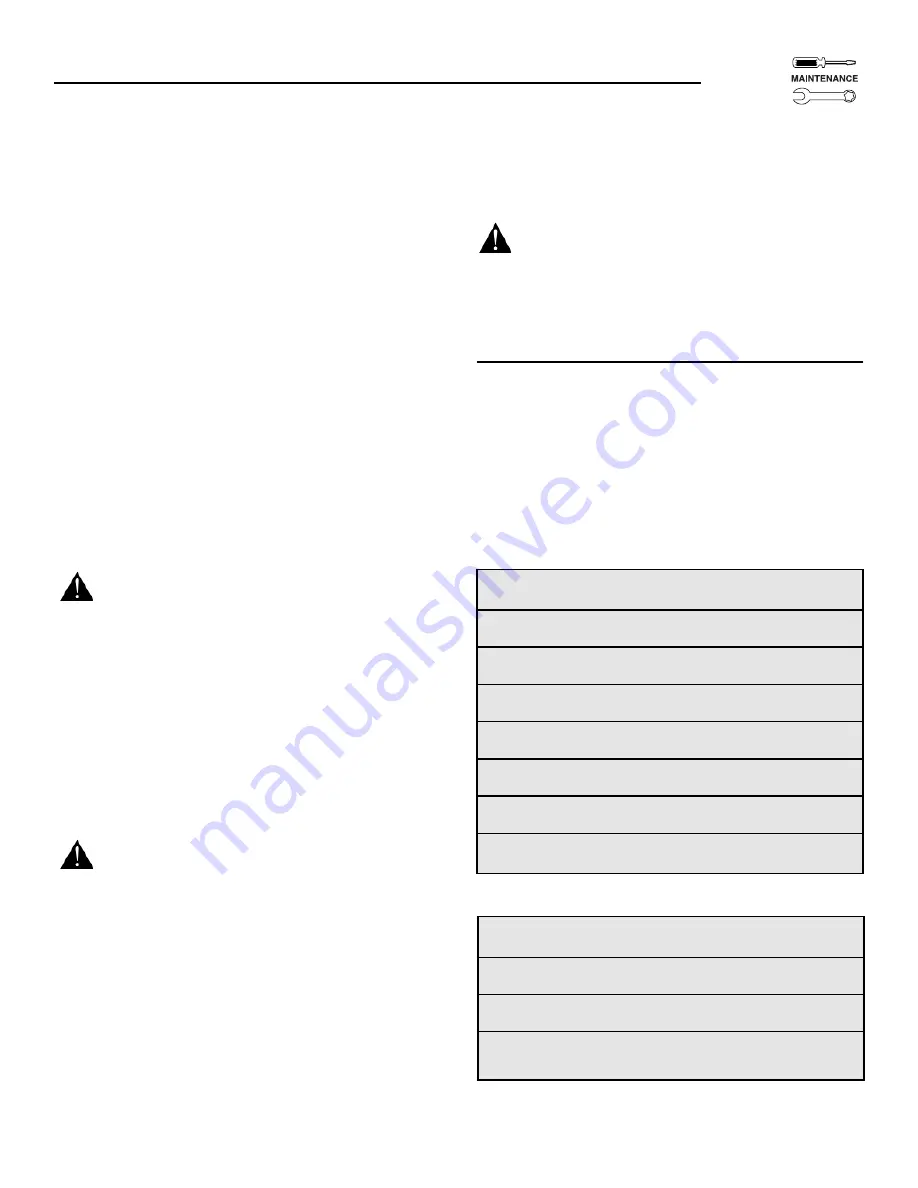

PRODUCT SPECIFICATIONS

MODEL

GTV-GTH-990

GTV-GTH-760

Bore

90mm

90mm

Stroke

78mm

60mm

Valve Clearance

0.05–0.10mm 0.05–0.10mm

(.002–.004 in)

(.002–.004 in)

Displacement

992cc

763cc

Maximum Tilt Angle

15°

15°

While Operating

Weight

(44.5 kg.) (98 lbs.)

(44.5 kg.) (98 lbs.)

OIL CAPACITIES

MODEL

GTV 990 & 760

GTH 990 & 760

Oil Capacity with Oil

2030 ml (2.1 qt.)

1750 ml (1.8 qt.)

Filter

Oil Capacity without

1750 ml (1.8 qt.)

1470 ml (1.5 qt.)

Oil Filter

GTV/GTH - 990/760 OHVI SERIES ENGINES