GB

•

Check to see that all iron parts that are hopping and could damage the machine while the job is being

done have been removed from the piece to be worked. The ends of the stems have to be cut square.

Any knags have to be cut off completely. .

•

Never cleave the stocks, the size of which is beyond the limits determined, it could cause injuries and

damage to the machine.

•

The wood should be cleaved along the grain. Never put a stock across the machine and never work it in

such a position; it could cause injuries and damage to the machine.

•

In no case cleave two stocks at a time. One of them could rebound and hit the operator!

•

If the stock slides down of the knife, pull the stock thrust device back and turn the stock by 180°.

•

Do not operate the wood cleaving machine at full for more than 10 - 15 seconds, e.g. holding the

cylinder pressed down or cleaving hard material. That would result in fast overheating the oil and

causing damage to the machine subsequently. It is recommended to turn the stock by 180° and to try to

work it in the position. If it is not possible to split up the stock, discard it, to avoid damage to the

machine.

•

Given unfavorable conditions in the power supply the equipment may cause the voltage to drop

temporarily.

•

If the supply impedance “Z” at the connection point to the public power supply exceeds 0,233

Ω

EN

61000-3-11

it may be necessary to take further measures before the equipment can be used as intended

from this power supply.

•

If necessary, you can ask your local electricity supply company for the impedance value.

Step-by-Step Instructions

•

Connect the motor wood-splitting machine to the power.

•

Connecting the power cable, mind that it is not let via a telescopic bearer or close to the

cleaving knife. Also, avoid any places where a risk of damage or disruption exists.

•

Place the stock on the bearer. The guides will assist you in keeping the stock at the centre of

the knife. If the stock does not fit tightly, it should be turned.

•

Push the motor control button with your LH to the stop and control the steering lever with your

RH at the same time.

•

The sliding desk will go forward, pushing the stock through the blade.

Notice: The switch contact could be destroyed if the button is not pushed to the stop.

Notice: Always push the switching button completely!

•

If the stock is not split up immediately, hold the cylinder on. Pull the stock sliding device back and

try again. A small stock may be difficult to work if it is knaggy and fibrous. With wood of regular

fibrous composition, it will not be difficult to work stock of larger diameter. If the wood is very hard,

the stock should be left for machine working to avoid damage.

•

Repeat the operation with pre-cut shorter pieces of wood.

•

With the work completed, the machine should be unplugged. Do not unplug pulling the cable.

Caution:

After several hours of work and at splitting big hard blocks, the motor may switch off

owing to the heat fuse function. Let the machine cool down for ca 15 minutes before getting to

work again.

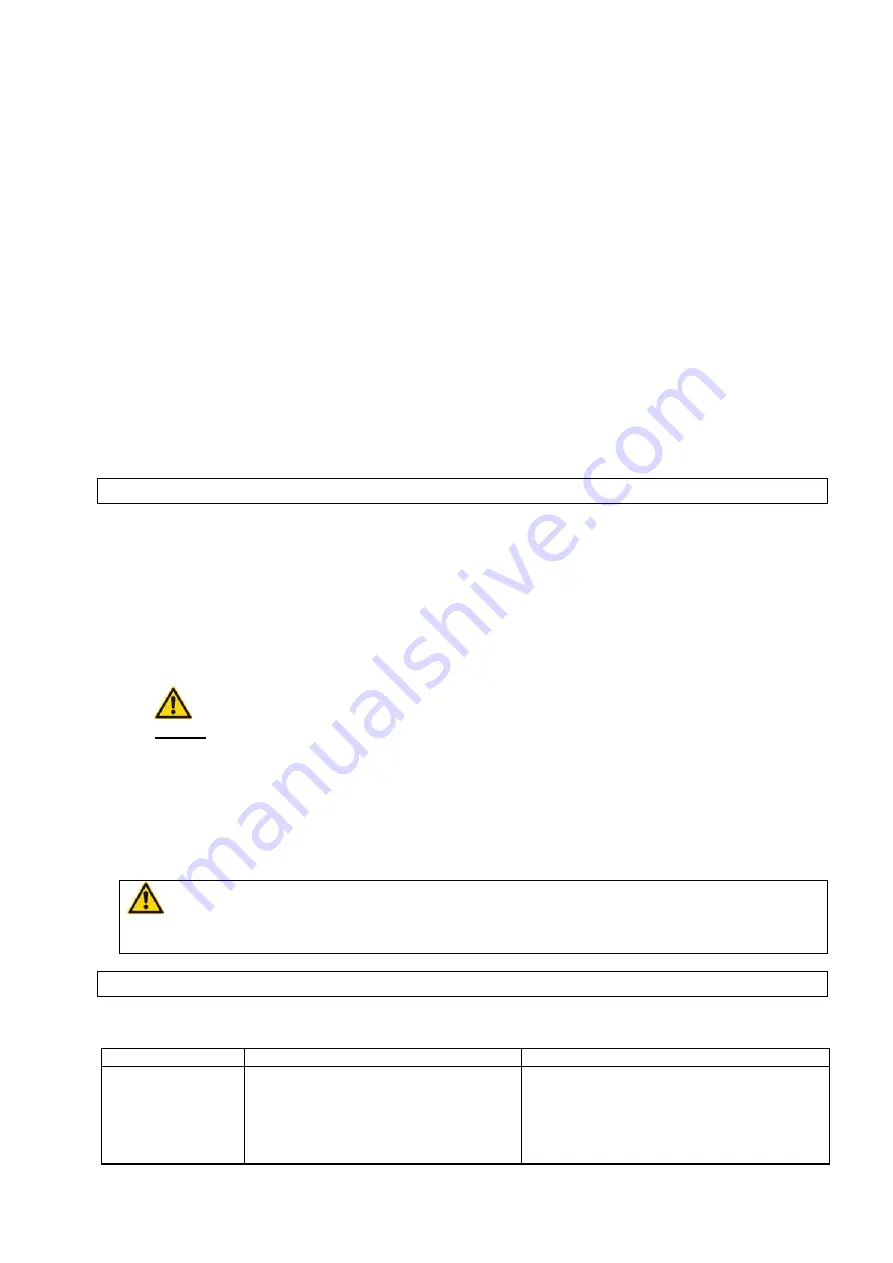

Troubles – Causes – Troubleshooting

CAUTION: ALWAYS CHECK THE THERMAL FUSE FIRST!

Trouble

Cause

Troubleshooting

The block will not rend

1.

Wrong positioning .

2.

The stock size not within permissible limits

or the wood too hard for the machine

capacity.

3.

The blade will not cut

4. Oil too cold

1.

Position the block

2.

Cut the block shorter, adjust

3.

Sharpen the blade check it for sharp edges or

recesses formation, or reface if necessary

4.

Warm up at idling. .

54