GB

5. Oil leakage

6. Hydraulic pressure too low.

5.

Find the place of leakage and seal it.

6. Discard

the

wood.

Jerky run or strong

vibrations of the piston

rod

Air in the circuit

Check the oil level, replenish, if necessary.

Inquire at the dealer’s if necessary.

Oil leakage at the

piston rod or outer

parts.

1. Oil leaking from the oil tank.

1. Worn gasket

Before positioning, check the bleed screw fit

Replace the gasket

The block to be split

has jammed

1.

The block too knaggy

1.

Retract the sliding worktable completely to release

the control .

Inspections and Maintenance

Prior to any maintenance, the machine should be put out of operation and unplugged, if it is an electric

drive machine. The maintenance not described in this manual should be done by skilled personnel only

as the operator is not ready to handle the situations that may arise. Scheduled maintenance and

replacement of parts should be done by special personnel only. The manufacturer should not be held

liable for any personal and material losses due to a failure to observe these rules.

Hydraulic Oil Change

HLP 46 (# 42004)oil is recommenced for the hydraulic cylinder

Or hydraulic oils of similar viscosity

•

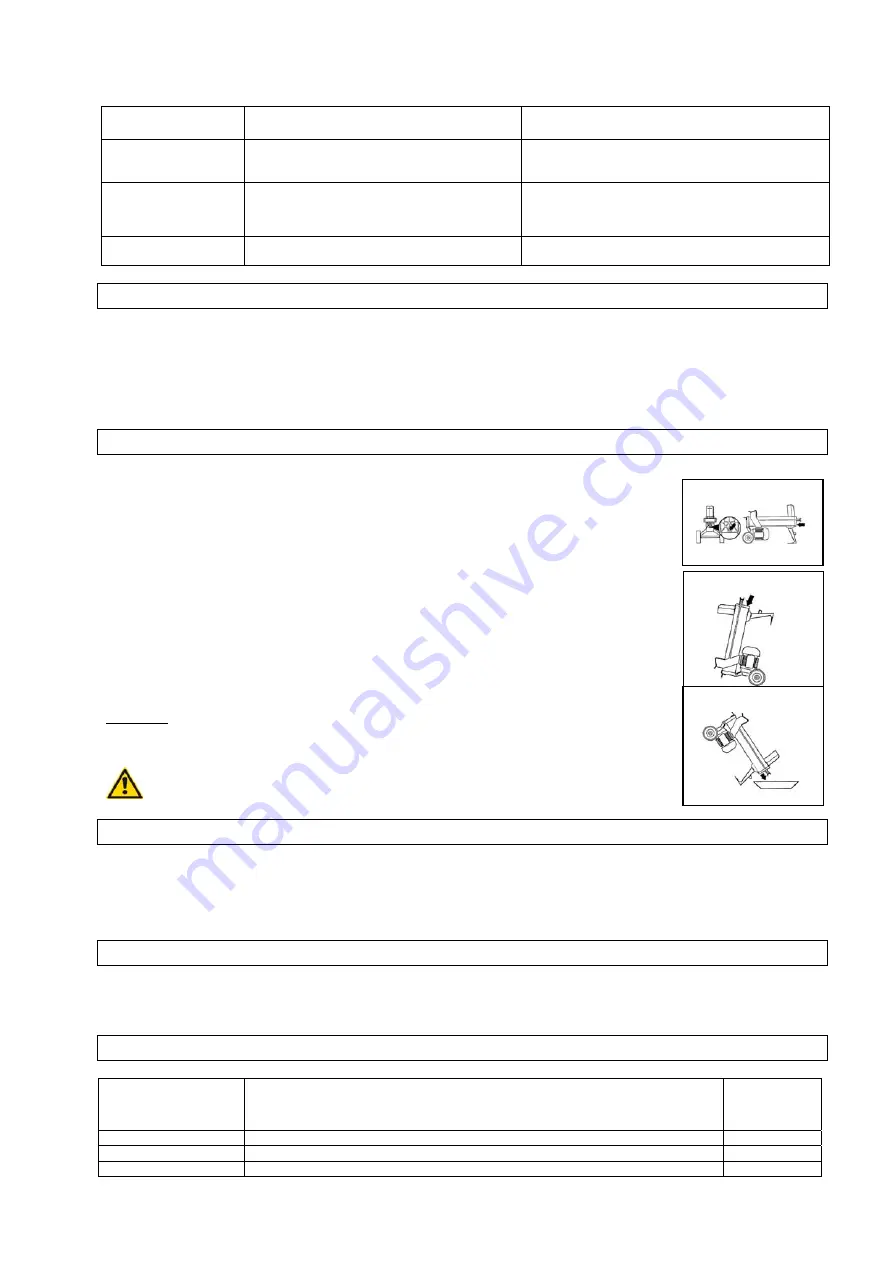

Make sure that the motor bearer is completely retracted.

•

Remove the screwed closure (Fig. 10/11).

•

Put a collecting tub of minimum volume of 4 litres under the splitting machine.

•

Tilt the machine for the oil to pour out (Fig. 12).

•

Tilt the cleaving machine in the other direction and pour 2.4 l of oil in the hole.

•

Use the oil level indicator – previously cleaned – and check the oil level. It should

be between the two marks on the indicator.

•

Clean the closure and the screw and close again.

NOTICE:

The used oil should be disposed of in conformity with the locally effective

legal regulations.

Check the oil level using an oil level indicator on a regular basis (Fig. 8).

Splitting Blade Sharpening

Sharp the splitting blade using a file on a regular basis. Remove any sharp edges and depressions

Grease the splitting blade with multipurpose grease on a regular basis. It will decrease the stress and

sometime, even the difficult to work stock may be cleaved.

Inspections and Maintenance Safety Instructions

The machine will serve as a sufficient aid only if maintained and care for appropriately. Insufficient

maintenance and care may result in accidents and injuries.

Inspections and Maintenance Schedule

Time Interval

Description

Other

details if

any

400 operating hours

•

Hydraulic oil change

HLP 46, 2,4 l

Before every use

•

Oil level check

Before every use

•

Check of the blade for sharpness and sharpening if necessary

Fig. 10

Fig. 11

Fig. 12

55