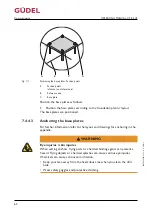

min. 15

00 mm

B

A

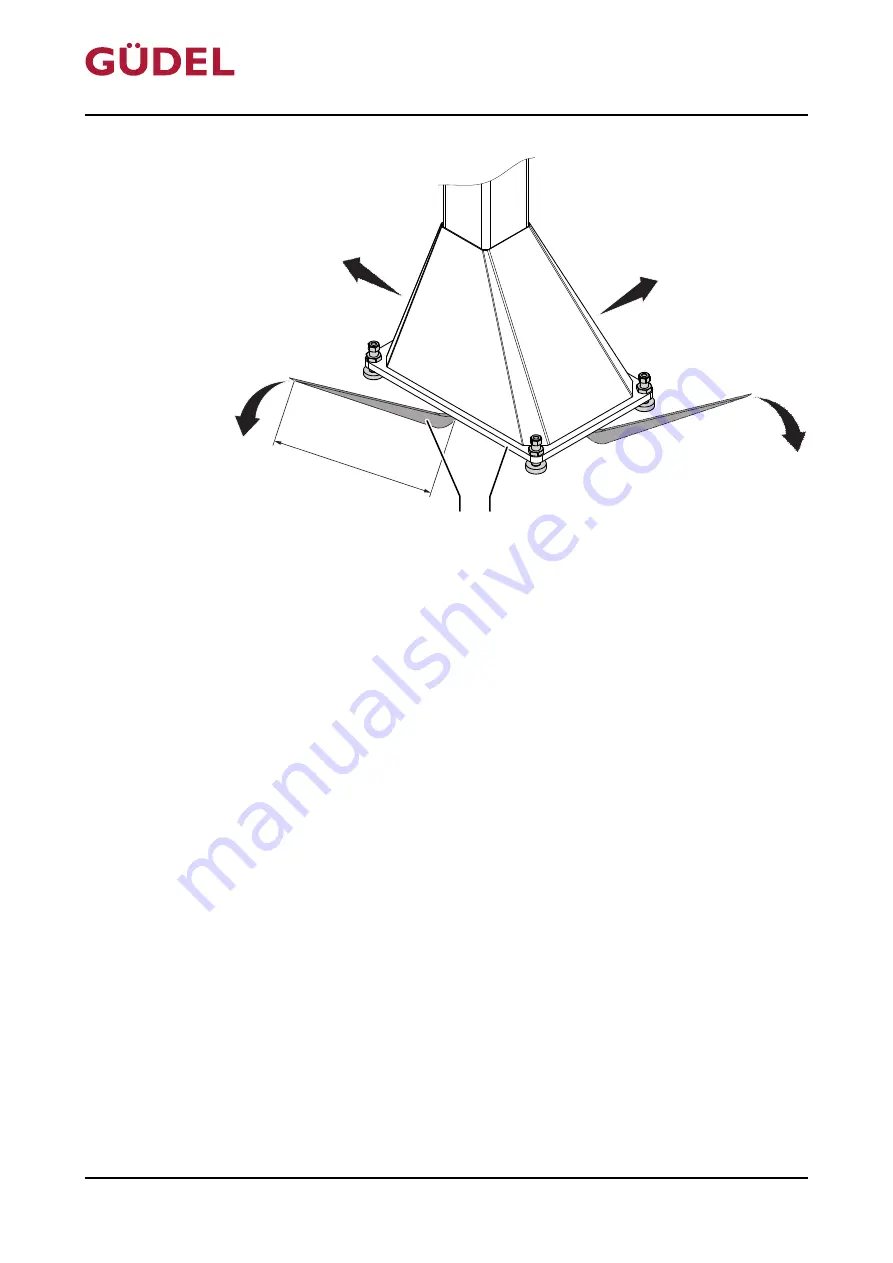

Fig. 7-9

Aligning upright and beam

A

Pry bar

B

Upright

Align the upright and beam as follows:

Prerequisite:There are no adjustment mechanisms present in the direc-

tion of movement

1

Place pry bar in desired position as shown in the illustration

2

Carefully move the upright in the direction of the arrow in small steps

Upright and beam have been aligned.

Commissioning

OPERATING MANUAL CP 3-5 V2

9007202252815371_v1.0_

EN-US

72

Summary of Contents for CP 3-5 V2

Page 4: ...Revision history OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US 4...

Page 16: ...Table of contents OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US 16...

Page 34: ...Safety OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US 34...

Page 42: ...Design function OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US 42...

Page 52: ...Transport OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US 52...

Page 130: ...Operation OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US 130...

Page 216: ...Maintenance OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US 216...

Page 218: ...Maintenance OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US 218...

Page 220: ...Maintenance OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US 220...

Page 222: ...Maintenance OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US 222...

Page 224: ...Maintenance OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US 224...

Page 228: ...Maintenance OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US 228...

Page 230: ...Maintenance OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US 230...

Page 232: ...Maintenance OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US 232...

Page 234: ...Maintenance OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US 234...

Page 236: ...Maintenance OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US 236...

Page 264: ...Repairs OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US 264...

Page 266: ...Repairs OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US 266...

Page 272: ...Decommissioning storage OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US 272...

Page 278: ...Spare parts supply OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US 278...

Page 284: ...Spare parts supply OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US 284...

Page 302: ...List of illustrations OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US 302...

Page 306: ...List of tables OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US 306...

Page 316: ...Appendix OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US...

Page 317: ...Hazard analysis Risk analysis Appendix OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US...

Page 318: ...Appendix OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US...

Page 323: ...Appendix OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US...

Page 326: ...Technical data Appendix OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US...

Page 327: ...Appendix OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US...

Page 328: ...Layout Appendix OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US...

Page 329: ...Appendix OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US...

Page 330: ...Spare parts lists Appendix OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US...

Page 331: ...Appendix OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US...

Page 332: ...Options Appendix OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US...

Page 333: ...Appendix OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US...

Page 334: ...Third party documentation Appendix OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US...

Page 335: ...Appendix OPERATING MANUAL CP 3 5 V2 9007202252815371_v1 0_EN US...