Loosen the cog belt as follows:

1

Remove the screw

2

Remove the locking plate

3

Loosen the straining screw

The cog belt is loosened.

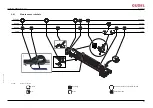

Removing cog belt

1

2

3

A

B

C

Fig. 9-31

Removing cog belt

A

Set screw

B

Belt anchorage

C

Cog belt

Remove the cog belt as follows:

1

Remove the set screws

2

Remove the belt anchorage

3

Remove the cog belt

The cog belt is removed.

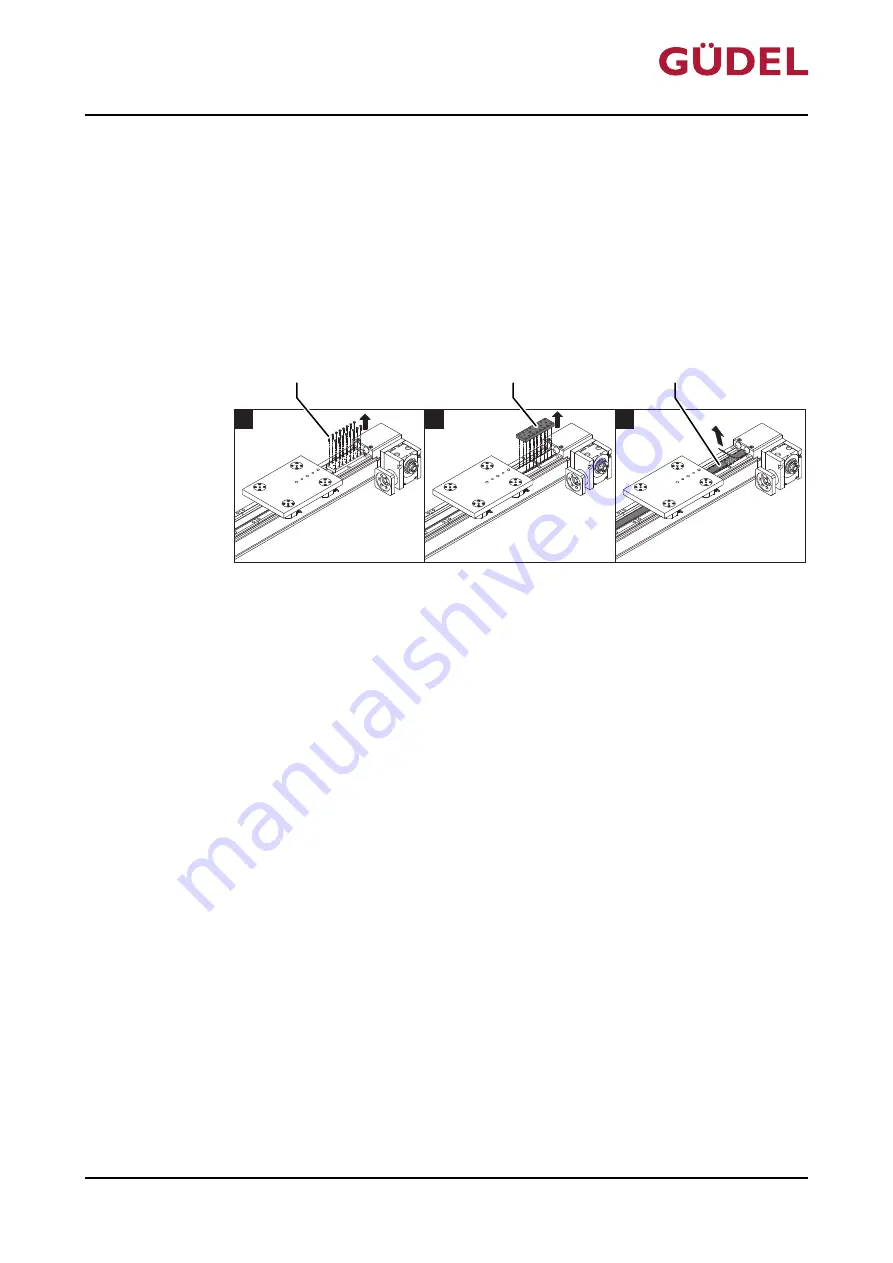

Replacing the cog belt

Replace the cog belt as follows:

1

Replace the cog belt

2

Transfer the markings of the old cog belt to the new cog belt if necessary

The cog belt has been replaced

Maintenance

OPERATING MANUAL MLB 1-3 V2

881017611_v1.0_

EN-US

149

Summary of Contents for MLB 1-3 V2

Page 4: ...Revision history OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US 4 ...

Page 14: ...Table of contents OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US 14 ...

Page 86: ...Operation OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US 86 ...

Page 159: ...9 4 Maintenance schedules Maintenance OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US 159 ...

Page 160: ...Maintenance OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US 160 ...

Page 162: ...Maintenance OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US 162 ...

Page 164: ...Maintenance OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US 164 ...

Page 166: ...Maintenance OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US 166 ...

Page 170: ...Maintenance OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US 170 ...

Page 172: ...Maintenance OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US 172 ...

Page 174: ...Maintenance OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US 174 ...

Page 176: ...Maintenance OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US 176 ...

Page 178: ...Maintenance OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US 178 ...

Page 180: ...Maintenance OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US 180 ...

Page 206: ...Repairs OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US 206 ...

Page 212: ...Decommissioning storage OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US 212 ...

Page 217: ...13 Spare parts supply Spare parts supply OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US 217 ...

Page 218: ...Spare parts supply OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US 218 ...

Page 224: ...Spare parts supply OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US 224 ...

Page 234: ...List of illustrations OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US 234 ...

Page 238: ...List of tables OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US 238 ...

Page 246: ...Index OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US 246 ...

Page 248: ...Appendix OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US ...

Page 249: ...Hazard analysis Risk analysis Appendix OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US ...

Page 250: ...Appendix OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US ...

Page 255: ...Appendix OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US ...

Page 258: ...Technical data Appendix OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US ...

Page 259: ...Appendix OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US ...

Page 260: ...Layout Appendix OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US ...

Page 261: ...Appendix OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US ...

Page 262: ...Spare parts lists Appendix OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US ...

Page 263: ...Appendix OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US ...

Page 264: ...Options Appendix OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US ...

Page 265: ...Appendix OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US ...

Page 266: ...Third party documentation Appendix OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US ...

Page 267: ...Appendix OPERATING MANUAL MLB 1 3 V2 881017611_v1 0_EN US ...