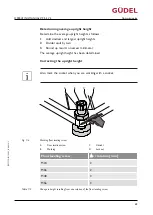

Determining average upright height

Determine the average upright height as follows:

1

Add smallest and largest upright heights

2

Divide result by two

3

Round up result to nearest millimeter

The average upright height has been determined.

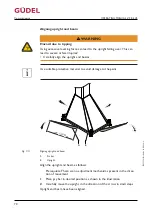

Correcting the upright height

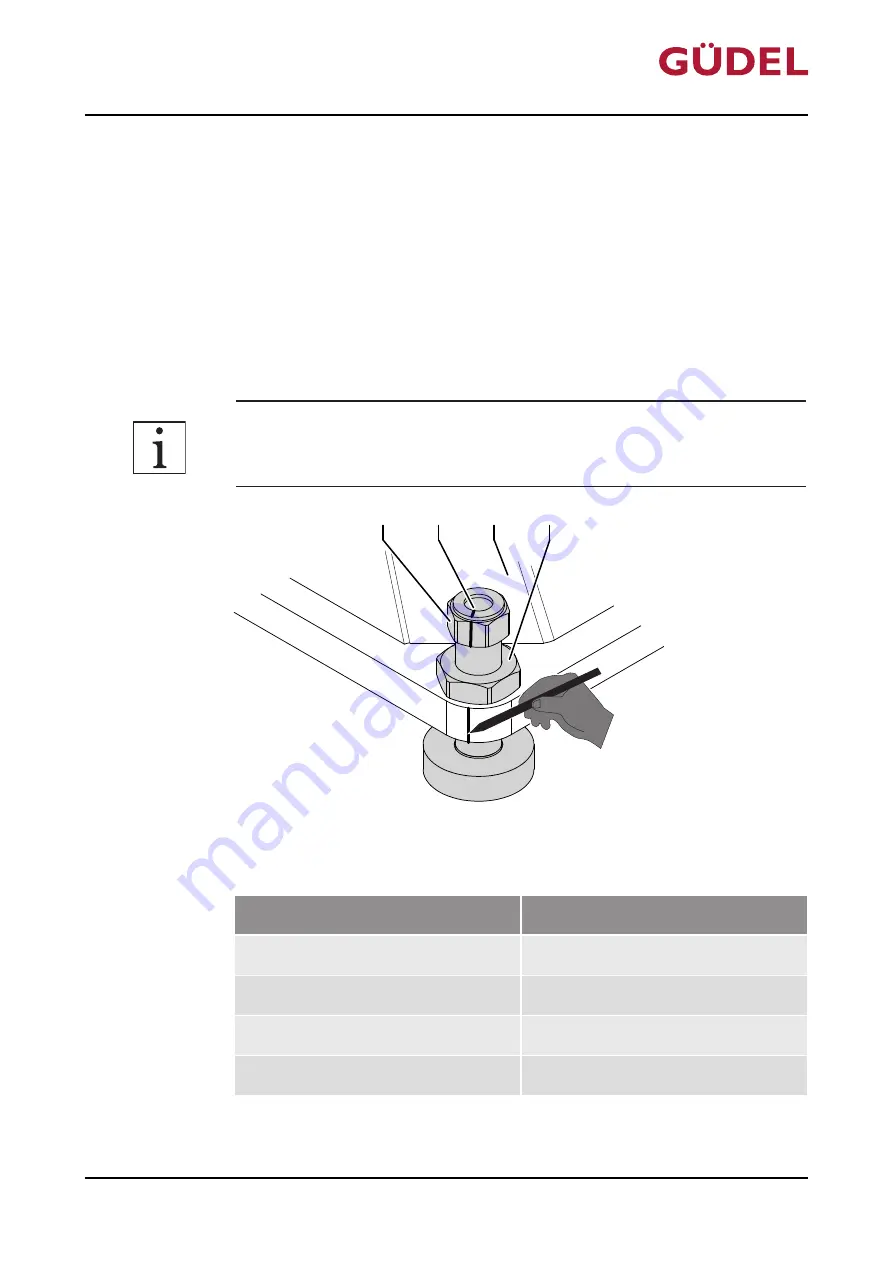

Also mark the socket when you are working with a socket.

A

B

C

D

Fig. 7-6

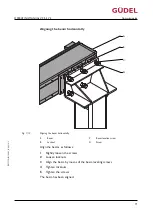

Marking floor leveling screw

A

Floor leveling screw

C

Upright

B

Marking

D

Locknut

Floor leveling screw

Δ

h / rotation [mm]

M24

2

M36

2

M48

3

M56

3

Table 7-2

Change in height resulting from one rotation of the floor leveling screw

Commissioning

OPERATING MANUAL ZP 3-5 V4

72057594174110603_v5.0_

EN-US

63

Summary of Contents for ZP 3-5 V4

Page 16: ...Table of contents OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US 16...

Page 46: ...Transport OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US 46...

Page 140: ...Commissioning OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US 140...

Page 142: ...Operation OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US 142...

Page 226: ...Maintenance OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US 226...

Page 228: ...Maintenance OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US 228...

Page 230: ...Maintenance OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US 230...

Page 234: ...Maintenance OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US 234...

Page 236: ...Maintenance OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US 236...

Page 238: ...Maintenance OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US 238...

Page 240: ...Maintenance OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US 240...

Page 242: ...Maintenance OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US 242...

Page 274: ...Repairs OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US 274...

Page 280: ...Decommissioning storage OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US 280...

Page 286: ...Spare parts supply OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US 286...

Page 292: ...Spare parts supply OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US 292...

Page 306: ...Illustrations OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US 306...

Page 310: ...List of tables OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US 310...

Page 318: ...Index OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US 318...

Page 320: ...Appendix OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US...

Page 321: ...Hazard analysis Risk analysis Appendix OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US...

Page 322: ...Appendix OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US...

Page 327: ...Appendix OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US...

Page 330: ...Technical data Appendix OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US...

Page 331: ...Appendix OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US...

Page 332: ...Layout Appendix OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US...

Page 333: ...Appendix OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US...

Page 334: ...Spare parts lists Appendix OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US...

Page 335: ...Appendix OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US...

Page 336: ...Options Appendix OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US...

Page 337: ...Appendix OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US...

Page 338: ...Third party documentation Appendix OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US...

Page 339: ...Appendix OPERATING MANUAL ZP 3 5 V4 72057594174110603_v5 0_EN US...