Customer Helpline

0333 3201989

10

a

Operating Instructions

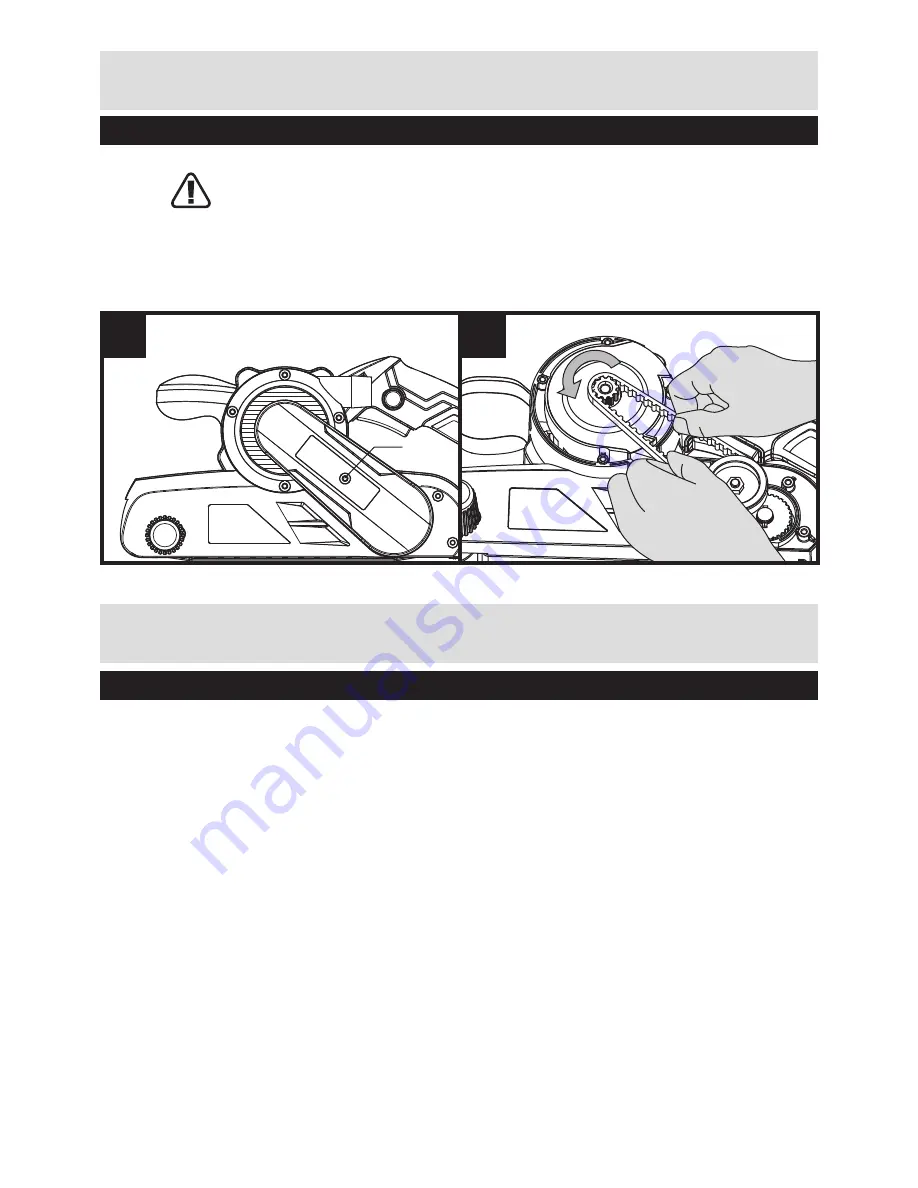

8. DRIVE BELT REPLACEMENT (SEE FIG H, I)

WARNING! Remove the main plug from the socket before carrying out a drive

belt replacement.

Remove the screw (a) and the belt cover as shown. Carefully

cut the drive belt if not already broken and remove from your belt sander. Fit your

new drive belt around the large pulley. Then install onto the small pulley by rotating

clockwise and pushing the drive belt shown around the small pulley at the same time.

The drive belt will be a tight fit. Fit the belt cover and three screws.

If your power tool becomes too hot, especially when used at low speed, set the speed to

maximum and run with no load for 2-3 minutes to cool the motor. Avoid prolonged usage at very

low speed. Always use a sanding belt suited to the material you wish to sand. Always ensure the

work-piece is firmly held or clamped to prevent movement. Support large panels close to the

sanding area. Any movement of the material may affect the quality of the sanding finish. Start

your sander before sanding and turn off only after stopping sanding. For best results sand wood

in the direction of the grain. Do not start sanding without the sanding belt fitted. Empty the dust

bag every 5 minutes or sooner to ensure efficient dust collection.

Working Hints For Your Belt Sander

H

I