9

1.11

GH2+2 ceiling hoist with built-in drive motor

GH2+2 ceiling hoist with a built-in drive motor operates fully automatically on

the rail system.

When using a GH2+2, please note that the motor uses approx. 1 second to

accelerate and stop the hoist, respectively. Thus, when stopping the unit from

max. speed, the motor must be cut off 10-15 cm before the desired position.

When the hand control is activated for a shorter period of time, it is possible

to position the hoist with a high level of accuracy.

GH2+2 must run on its own power and should not be pulled through the rail

system.

1.12

GH2+2R ceiling hoist with built-in drive motor and infrared remote control

GH2+2R has a built-in drive motor and IR receiver which is controlled by the

IR sender.

With this sender, it is possible to control all the functions of the hoist.

Furthermore, the IR sender can be used to control e.g. switch tracks,

combi-locks and turntables mounted with IR receivers.

The cable-mounted hand control must remain fitted to the hoist. This will

ensure that the hoist can always be operated if the IR sender is mislaid

or if its batteries run dry.

In certain cases, an unladen hoist with a drive motor can, due to its low

unloaded weight, have difficulty in driving through, for example, switch

tracks, if the switch is not open in the direction in which the hoist is passing.

To provide extra security for unassisted users that the hoist runs smoothly

through the track system, it is possible to mount a friction enhancer in

connection with the hoist’s drive wheels. Friction enhancers cannot be

used in connection with a drive-through charging station.

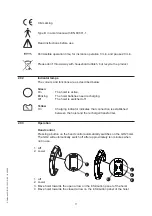

Friction enhancers are mounted as follows:

1. Move the hoist to the end of the rail, making sure that the drive wheels are

free of the rail.

2. The friction enhancer is placed over the wheels as shown. The long pins on

the friction enhancer must point in the direction of the nearest end of the hoist.

3. Run the hoist into the rail again. Check

that the friction enhancer is functioning by

holding onto the hoist with the drive motor

in operation. The hoist must pull strongly

in both drive directions.

©

Guldmann

G

B

/U

S

-12

63/0

1

/0

8

•

#

90069

©

Guldmann

G

B

/U

S

-12

63/0

1

/0

8

•

#

90069