Supplied By www.heating spares.co Tel. 0161 620 6677

Page 24

5.3 CLEANSING AND WATER TREATMENT

5.3.1 Water Treatment

WARNING: We only recommend ‘Fernox Superfloc’ cleaning agent and Fernox MB1

protector for this appliance. The correct use of cleaning agent and the correct

strength of inhibitor is essential for the efficient and long life of this appliance.

Failure to do this correctly will result in premature corrosion of the boiler/blocking

of the waterways and neither of these situations will be covered by the appliance

warranty.

The correct quantities of cleaning and treatment agents should be determined from

the manufacturer’s instructions and the 100 litre water content of the store must

be included. General guidelines for quantities of cleansing and treatment agents

are shown in table 5.1.

(a) Ensure that all cleansing/treatment of the heating system is carried out fully in

accordance with the instructions provided by Fernox.

(b) The water system must be thoroughly flushed out, initially with cold water and

ensuring that all valves are fully open.

(c) Refill the system to normal working pressure. Examine for water leaks. Rectify if

necessary.

(d) Add Fernox Superfloc Cleansing Agent to ensure that all flux residues and

installation debris are removed from the system.

(e) Heat the system to full operating temperature, check for water leaks and rectify

if necessary. Flush the system again until it is clean.

(f) Refill the system and add Fernox MB1 Protector to the system ensuring that the

system is fully vented.

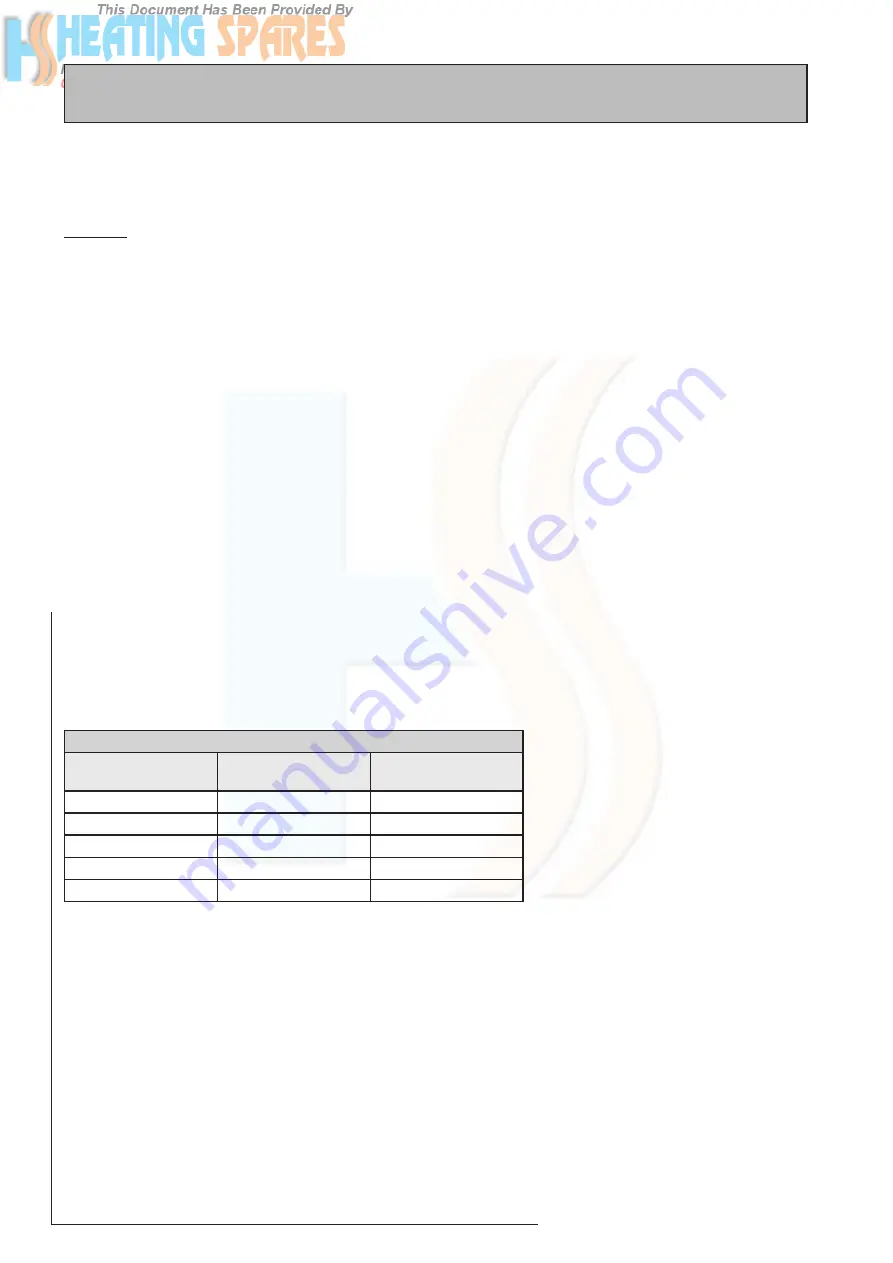

Table 5.1 Quantities of cleansing and treatment agents (litres)

Heating circuit design

heat loss (kW)

Fernox

Superfloc

Fernox

MB1

6

5.0

1.2 - 2.4

12

5.9

1.5 - 3.0

18

6.9

1.7 - 2.4

24

7.8

2.0 - 4.0

30

8.8

2.2 - 4.4

5.3.2 Power Flushing/Cleaning of the

Heating System

(a) When carrying out the work, always comply

fully with the manufacturers’ instructions for

the power flushing equipment.

(b) We would always recommend that the

GulfStream

A-ClASS

appliance is isolated from

the heating system being cleaned.

(c) If in any doubt, please consult our Technical

Help line.

5.4 FLUE SYSTEM

(a) The flue system should have been designed

and installed in accordance with the

requirements under ‘Flue System Design,

section 3.4’ in this manual.

(b) Check that sealing of terminal(s) and pipes

is sound and acceptable.

(c) Check that horizontal lengths of flue pipe fall

back to the boiler and that there are no low

points where the condensate could collect.

COMMISSIONING

Summary of Contents for GS A-Class 12/OV

Page 39: ...Supplied By www heating spares co Tel 0161 620 6677 Page 39 GULFSTREAM A CLASS ...

Page 40: ...Supplied By www heating spares co Tel 0161 620 6677 Page 40 ...

Page 41: ...Supplied By www heating spares co Tel 0161 620 6677 Page 41 GULFSTREAM A CLASS ...

Page 42: ...Supplied By www heating spares co Tel 0161 620 6677 ...

Page 43: ...Supplied By www heating spares co Tel 0161 620 6677 ...

Page 44: ...Supplied By www heating spares co Tel 0161 620 6677 ...