Operating Manual

Troubleshooting

2/12/04

27

Proportioning System

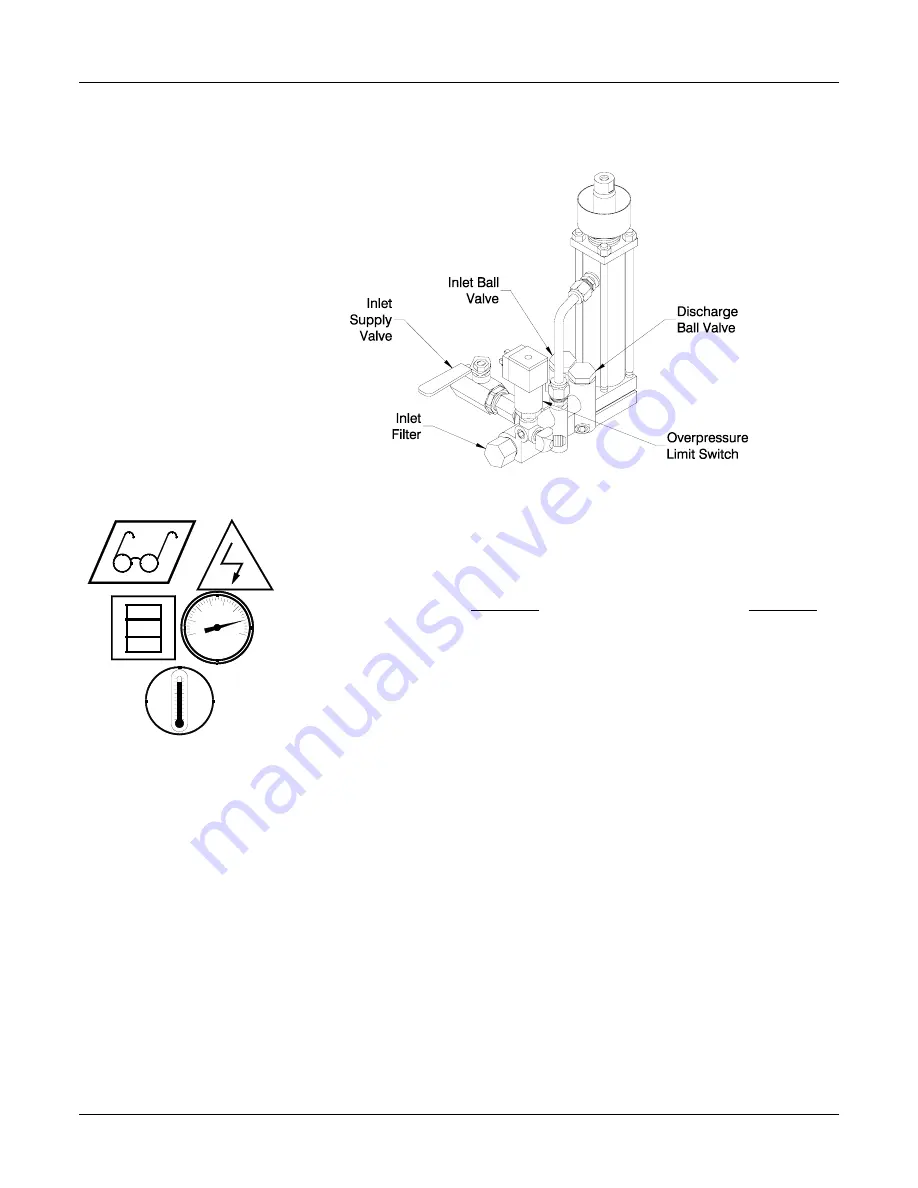

Figure 15. Proportioning Pump Features

Try the recommended solutions in the order given for each problem to avoid unnecessary

repairs. Also, determine that all circuit breakers, switches, and controls are properly set

and wiring is correct before assuming there is a problem. Turn off all switches and allow

the chemicals to cool before attempting troubleshooting procedures.

Problems Solutions

Proportioning pump does not hold pressure when stalled.

1

Pressure imbalance between pumps.

2,3,1

Cavitation in the proportioning pump.

2,3,1

Failure of the pump to reverse.

4,7

Pumps do not move and the directional indicator lights are out.

4,5,6

Pump movement is erratic.

7

Unequal pressure or speed on the upstroke verses the down stroke.

8

S

OLUTIONS

1. LEAKING BALL CHECK VALVE -Determine which inlet and discharge ball valve

is leaking by observing the pressure gauges. If the pump (A or R) is losing pressure

on the upstroke, check the discharge valve of the respective pump. If the pump is

losing pressure on the down stroke, check the inlet valve of the respective pump.

a)

Disconnect the air supply to the transfer pumps and proportioning unit.

b)

Close the inlet supply valve of the problem pump and bleed chemical

pressure in the transfer pump to zero.

c)

Bleed chemical pressure in the proportioning pump to zero.

d)

Remove the appropriate valve cover and use a magnet to remove the

valve ball.

e)

Flush and wipe clean the valve ball and ball seat of all residual

material. Inspect these parts for damage.