19

GT4.0 TREADMILL

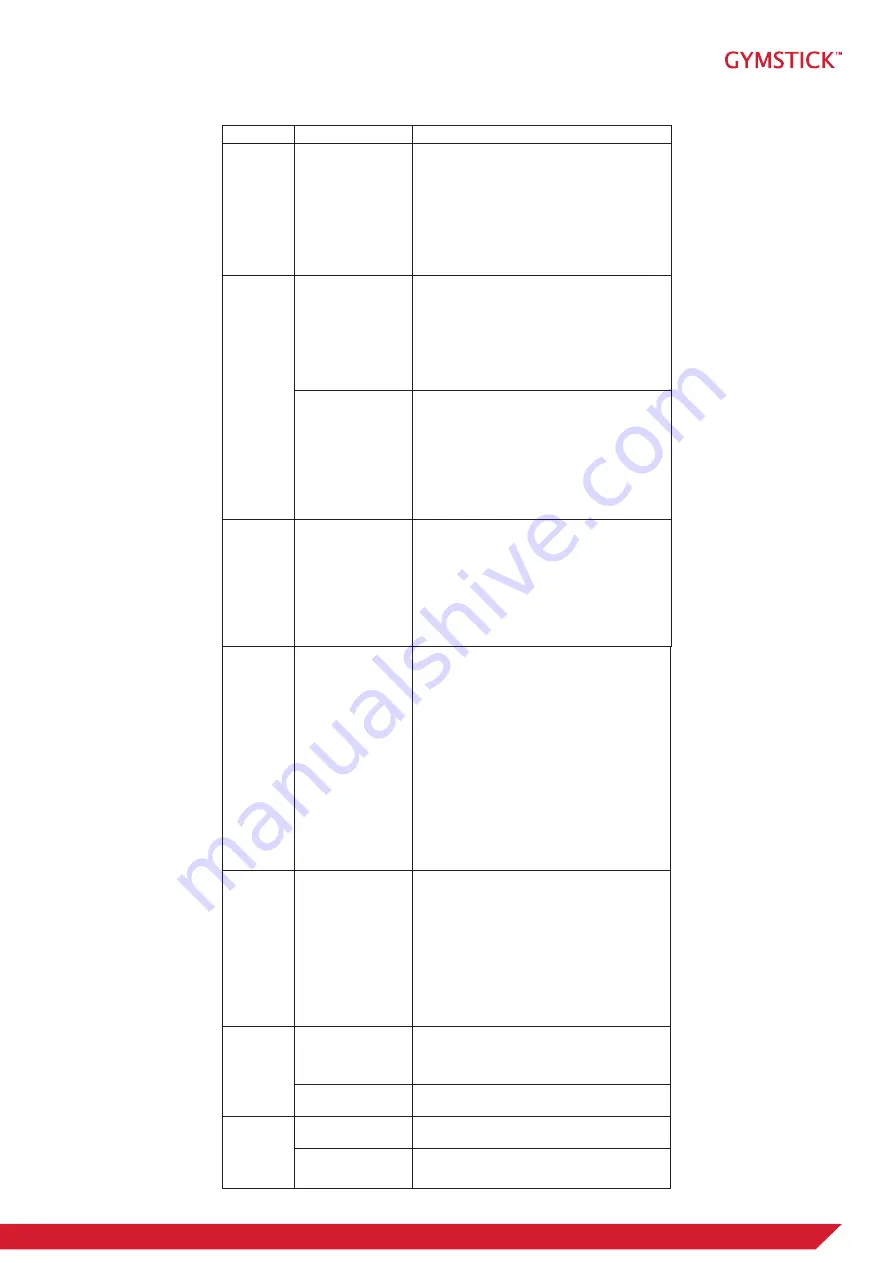

TROUBLESHOOTING

CONSOLE

Item

trouble

Maintenance

E1

Communication

abnormal:The

communication

between

the

controller and the

electronic watch is

abnormal

after

power is applied.

Broken controller couldn’t working. Console display

fault code and the buzzer sounded 3 times.

Reason: the poor communication between controller

and

console.

Checking

each

connection

of

communication wire between console and controller.

Make sure each core is completely inserted. Check

the connection wire, if it was broken, change it.

E3

The motor line is not

connected properly

The treadmill stop working and enter a fault state when

the buzzer sounded 9 times. The console display fault

code while the rest areas do not display anything. If

console discovery normal state and enter standby state

after treadmill stop working, the treadmill can restart.

Reason: make sure the well connection of the motor

wire and connect the wire again. If the controller has

peculiar smell, replace the controller.

No signal of speed

sensor: a voltage from

controller is output to

the DC motor. The

motor speed feedback is

not

continuously

received for more than 3

seconds.

The treadmill stop working and enter a fault state when

the buzzer sounded 9 times. The console display fault

code while the rest areas do not display anything. After

maintaining the fault state for about 10 seconds, enter

the standby state and restart the machine.

Reason: no speed sensor signal is detected for 3

consecutive seconds, check whether the sensor plug is

not plugged in or damaged, plug it in or replace the

sensor.

E4

Ascending

by

self

learning

Check whether the induction line of the lifting motor is

plugged in properly and plug the connector again to

make it reliable. Check whether the AC line of the

lifting motor is plugged correctly, and the AC line of

the lifting motor is correctly numbered with the mark on

the controller. Check whether the connecting wire of the

motor is damaged or open, replace the connecting wire

or lift the motor; After checking all, press the learning

key on the control to learn again.

E5

Over

current

protection

˖

under the

running state, the down

control

continuously

detects that the DC

motor current is greater

than the rated current

+6A for more than 3

seconds.

The treadmill stop working and enter a fault state when

the buzzer sounded 9 times. The console display fault

code while the rest areas do not display anything. After

maintaining the fault state for about 10 seconds, enter

the standby state and restart the machine.

Reason: over - rated load leads to over-current and

self-protection of the system, or a certain part of the

treadmill is stuck, resulting in motor failure, over-load

and over-current and self-protection of the system.

Adjust the treadmill and restart it. Check whether the

motor has over-current sound or burnt smell when

running, and replace the motor; Or check whether the

controller has burnt smell and replace the controller; Or

check whether the power supply voltage specification is

inconsistent or low, and retest with the correct voltage

specification.

E6

Explosion

-

proof

protection:

abnormal

power supply voltage or

abnormal motor will

cause damage to the

drive motor circuit.

The treadmill stop working and enter a fault state when

the buzzer sounded 9 times. The console display fault

code while the rest areas do not display anything. After

maintaining the fault state for about 10 seconds, enter

the standby state and restart the machine.

Reasons: check whether the power supply voltage is

lower than 50% of the normal voltage, please retest

with the correct voltage specification; Check whether

the controller has peculiar smell and replace the

controller; Check whether the motor line is connected

properly and reconnect the motor line.

LCD display

no value of

pulse

A.

The

handle

communication wire

didn’t plug well or

broken handle wire

Check and connect the wire well or change handle

wire.

B. Broken wire of

console

Change the console

Console

incomplete

display

or

lack

of

strokes

A. Loose screw of

display board

Tighten the screw

B. Broken system

Change the console