19

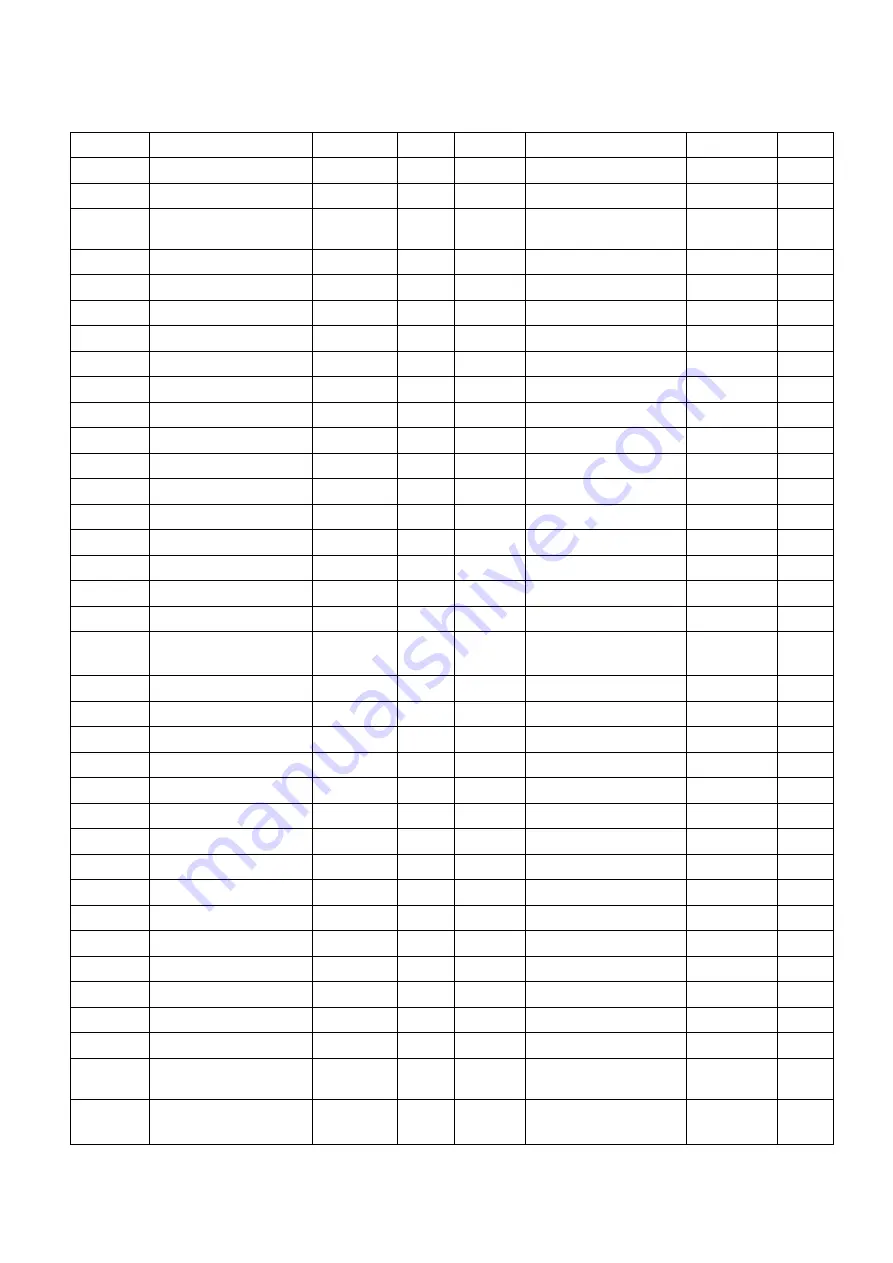

Parts list

#.

DESCRIPTION

REMARK

QTY

#.

DESCRIPTION

REMARK

QTY

1

Main frame

1

39

Start/stop Pulse

2

2

Base frame

1

40

Control circuit board

1

3

Left upright tube

1

41

Computer

bottom

wire

1

4

Right upright tube

1

42

Computer up wire

1

5

Motor bracket

1

43

Rubber pad 2

2

6

Computer bracket

1

44

Magnetic Ring

1

7

Rubber pad

8

45

Blue Single-Line

1

8

Rotating tube

2

46

Hexagon cap screw

M8*25

1

9

Front roller

1

47

I - Hexagon nuts

M6

2

10

Back roller

1

48

Screw

ST4.2*19

2

11

Air Pressure Bar

1

49

Hexagon cap screw

M6*55

1

12

5# Allen Wrench

5mm

1

50

Hexagon cap screw

M6*65

2

13

Cross Bolt

M5*15

5

51

Hexagon cap screw

M8*16

10

14

DC Motor

1

52

Hexagon cap screw

M8*12

2

15

Running Board

1

53

Hexagon cap screw

M8*40

3

16

Adjust food pad

2

54

Hexagon cap screw

M10*70

2

17

Circle plug

2

55

Flat Washer C Class

8

7

18

Motor cover

1

56

Screw

ST4.2*12

10

19

Motor bottom cover

1

57

Cross

pan

had

screw

M5*8

4

20

Side staps

2

58

I - Hexagon nuts

M8

4

21

Right end cap

1

59

I - Hexagon nuts

M10

2

22

Left end cap

1

60

I-Hexagon nuts

M8

4

23

Fixing Plug

2

61

Oil bottle

1

24

Drive belt

1

62

screw

ST4.8*19

4

25

Power cord

1

63

Lock Washer

5

2

26

Running belt

1

64

Lock Washer

8

16

27

Foot pad

4

65

Lock Washer

6

3

28

Ring shaped power

line plug A

1

66

Lock Washer

10

6

29

Transport wheel

2

67

Spring washer

8

6

30

Wheel cover

2

68

Hexagon cap screw

M6*27

2

31

Standard power cord

1

69

Hexagon cap screw

M6*30

8

32

Power Switch

1

70

Hexagon cap screw

M8*45

4

33

Foam grip

2

71

Safety Key

1

34

Screw

ST4.2*13

9

72

Safety Key inductor

1

35

Computer

bottom

cover

1

73

Safety Key metal

plate

1

36

Computer shrouding

1

74

Computer

face

sticker

1

Summary of Contents for RUN 3.0

Page 1: ...1 RUN 3 0 TREADMILL USER MANUAL...

Page 18: ...18 Exploded Diagram...