10

Operating manual

KOOLWELD 1

Translation of the original

instructions

SET UP - OPERATING THE DEVICE

Only experienced personnel, authorised by the manufacturer, may set up and install the device. During setup, ensure that the power source is

disconnected from the mains power supply. Serial or parallel power source connections are not allowed.

DESCRIPTION

The KOOLWELD 1 cooling unit is designed to cool liquid TIG torches (L).

The cooling unit is controlled directly by the power source through the power cable (I-5).

KOOLWELD 1

Power source compatibility

TITANIUM 230 AC/DC FV

This equipment is equipped with:

- a water level safeguard to prevent the water level from becoming too low for the unit, as well as the torch’s water-cooling feature, to operate properly.

- a water flow safeguard to prevent clogs in the torch’s water supply system and damage to the torch.

- a thermal safeguard to protect the torch against abnormal heating.

This equipment is automatically detected by the power source.

TITANIUM:

Select «System/Cooling unit» on the HMI:

- AUTO: activates when welding and deactivates the cooling unit 10 minutes after the welding is finished.

- ON: the cooling unit is permanently switched on.

- OFF: the cooling unit is switched off.

- PURGE

: a feature that is designed to purge the cooling unit or fill the water circuit; these safeguarding features are then deactivated.

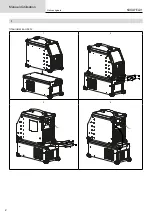

PRODUCT DESCRIPTION (II)

1.) Fill plug

2.) Coolant outlet (blue)

3.) Coolant inlet (red)

4.) Filling gauge

5.)

Power cable

6.) Priming hose

PRIMING THE COOLING UNIT

When used for the first time or after emptying the tank completely, starting the pump may be difficult and may result in a lack of water flow. Use the

priming hose supplied with the product (II-6) and follow the instructions below to prime it correctly:

- Fill the coolant tank to its maximum level. The tank has a three-litre capacity.

- Connect the priming hose to the coolant outlet connector (II-2) and place the other end in an empty container (ideally a bottle).

- Turn on the power source.

TITANIUM:

On the HMI, select «System/Cooling Unit» and click on the icon

to start the priming procedure.

- Once the pump is running (with the container filling with coolant), stop the cooling unit by pressing one of the buttons on the HMI.

- Disconnect the ignition hose and refill the fluid in the cooling unit: the pump is now primed.

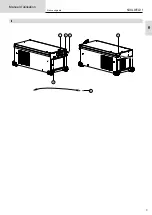

LIQUID COOLING

FILLING THE DEVICE

MAX

MIN

The cooling unit tank must be filled to the gauge’s recommended MAX level on the front of the cooling unit. However, it must never fall

below the MIN level, otherwise a warning message will appear.

Use only a specific coolant designed specifically for welding machines; it must have with low electrical conductivity as well as being

protected against corrosion and freezing (P.N. 062511).

Using other coolants, in particular a standard automotive coolant, may lead to an electrolytic build-up of solid deposits in the cooling

system which, in turn, may lead to poor cooling performance and even blockages in the cooling circuit.

The recommended MAX level is essential for optimising the liquid-cooled torch’s operational performance.

Any damage to the machine caused by using a coolant other than those stipulated in these instructions will not be covered by the

machine’s warranty.