5

DESCRIPTION

Thank you for choosing our product! To get the best of your equipment, please read carefully the following.

Plasma 21, 21 K and 31FV are inverter plasma cutters, portable, single phase, ventilated. They enable to cut in direct

current (DC) steel, stainless steel, aluminium, copper. They work with a single phase 230V input for the plasma

21/21KF, a single phase input spread between 85V to 265V for the plasma 31FV They are over-voltage protected when

used on power generators

POWER SUPPLY – START UP

•

This machine is delivered with a 16A plug type EEC7/7. The Plasma 21 /21KF must be plugged on a 230 V (50-60Hz)

socket

with

earth. The plasma 31FV integrates a « Flexible Voltage » system. It has to be on a power suply variable

between 85V and 265V (50 – 60 Hz)

WITH

earth. The absorbed effective current (I1eff) is shown on the machine,

for maximal using conditions.

Check that the main supply and its protections (fuse and/or circuit breaker) are compatible with the required current

in use.

•

To start the equipment, turn on the potentiometer to the desired current position (put the potentiometer on "O" for

standby mode).

•

The machines are protected against overvoltages and pass automatically in standby mode if the supply voltage

exceeds 265V. To point out this defect, the yellow indicator for thermal protection blinks twice then lights off. Normal

operation will resume after thirty seconds when the voltage has returned to its nominal range.

•

This appliance is dedicated for use in industrial environment according to CISPR 11. In a different environment, it can

be difficult to insure the electromagnetic compatibility. Do not use in an environment containing metallic dust

particles which may conduct electricity.

•

These are A-class devices. They are designed to be used in an industrial or professional environment. In a different

environment, it can be difficult to ensure electromagnetic compatibility, due to conducted disturbances as well as

radiation.

•

From 1st December 2010, the new standard EN 60974-10 will be applicable for plasma 21/21KF: Warning: these

materials do not comply with IEC 61000-3-12. If they are to be connected to a low-voltage mains supply, it is the

responsibility of the user to ensure they can be connected. If necessary consult the operator of your electrical

distribution system.

CUTTING

•

Connect the unit to the electricity network and to the air distribution (PLASMA Cutter 20/30 only)

•

Adjust the pressure regulator (PLASMA Cutter 21 and 31FV only) in order to have 2.5 to 4 bar for Plasma 21 or 2,5 to

6 bar for Plasma 31 on the manometer.

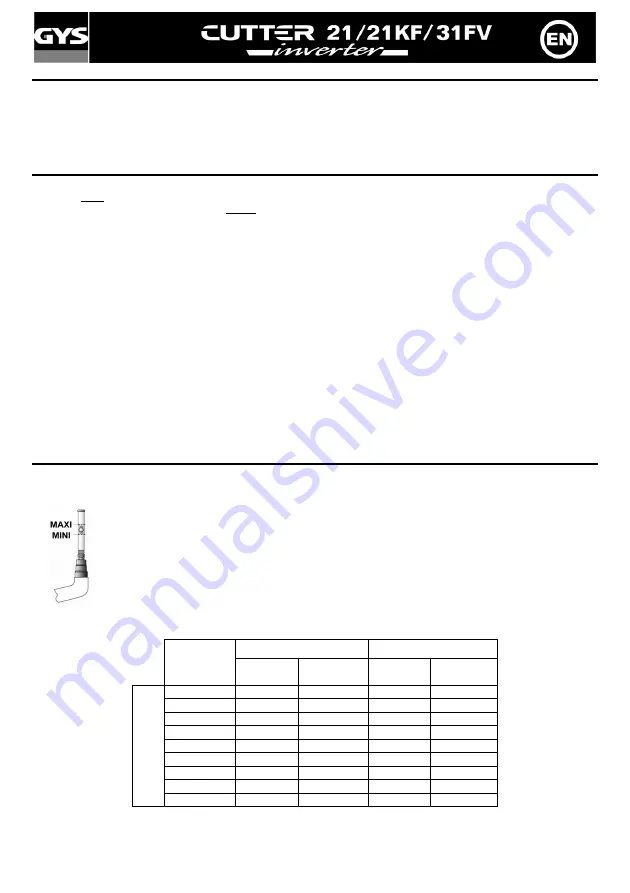

For the plasma 31FV : From 10 A* and to optimize the cutting performances, use the « air flow tester »

supplied with the machine. Process :

-

Press the torch trigger (the arc is appearing).

-

Release, the electrical arc stops but the air continues to flow for about 15 seconds.

-

During this time, put your « air flow tester » at the end of your torch, then adjust your air flow

(80l/mn for the 21 and 115l/mn for the 31) by placing the ball inbetween the mini/maxi zone.

*nb : For a cutting < 10A, directly adjust to 3 bars.

•

Switch on the unit.

•

Adjust the current according to the type of metal and the thickness to cut.

Plasma 21 / 21KF

Plasma 31FV

Thickness

(mm)

Current

(A)

Speed

(m/min)

Current

(A)

Speed

(m/min)

0,6

5

4,1

5

4,1

1

12

2,5

12

2,5

1,5

15

1,2

15

1,2

2,5

18

0,65

18

0,65

3

20

0,35

20

0,35

4

20

0,26

20

0,26

6

20

0,15

25

0,20

8

-

-

30A

0,16

S

te

e

l

10

-

-

30

0,09