6

0,6

8

2,5

8

2,5

1

12

1,2

12

1,2

1,6

15

0,65

15

0,65

2,5

20

0,25

20

0,25

4

20

0,15

25

0,21

6

-

-

30

0,23

A

lu

m

in

iu

m

8

-

-

30

0,09

•

Connect the earth clamp on a stripped zone of the piece to cut.

•

The PLASMA cutting machine is equipped with pilot arc system. This system allows starting the arc without touching

the piece to cut. You have 2 ways to cut your piece :

▪ Press on the trigger

pilot arc formation

cutting by contact with the piece.

▪ Contact with the piece

press on the trigger

immediate cutting

•

During the cutting, make sure to maintain the contact between the nozzle and the piece to cut.

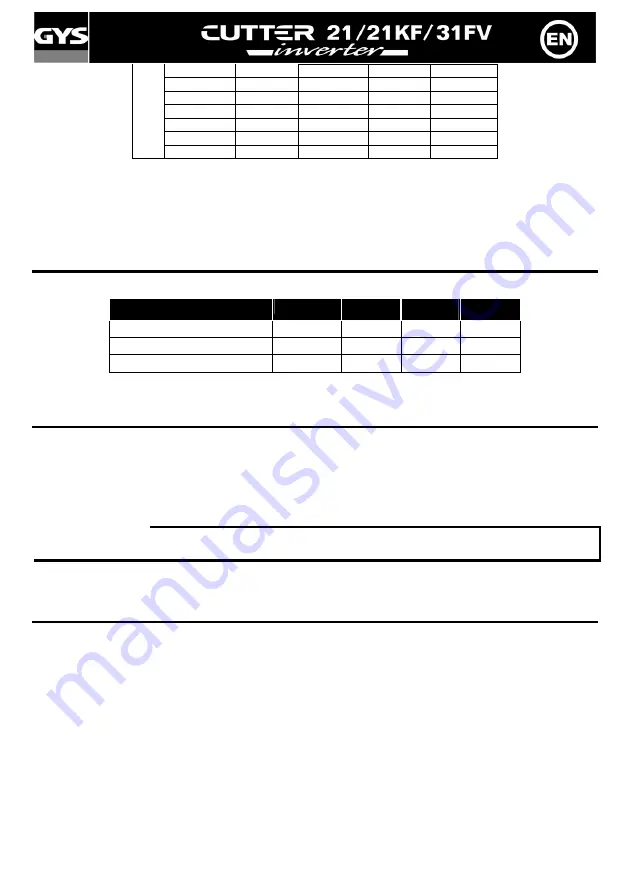

DUTY CYCLE

The machines described have an output characteristic of 'constant current' type. The duty cycle are indicated in the

table below according to EN60974-1 Norm.

X / 60974-1 @ 40°C

(T cycle = 10 min)

Plasma 21

Plasma 21KF

Plasma 31

(230V)

Plasma 31

(110V)

I max

34% @ 20 A

26% @ 20 A

32% à 30A

25% à 30A

60% (T cycle = 10 min)

16 A

12 A

22 A

19 A

100% (Tcycle = 10 min)

13 A

11 A

18 A

15 A

Note: the running hot tests have been carried out at atmosphere temperature and duty cycle has been determined at

40°C by simulation.

MAINTENANCE

•

Refer all servicing to qualified personnel.

•

Disconnect the generator and wait until the ventilator stopped before working on the unit. Inside the device,

voltages and current are dangerous.

•

We suggest removing the steel cover 2 or 3 times a year and remove any excess dust. Let check the electrical

connections (with an insulated tool) and the insulations by qualified personnel.

•

Regularly control the state of the cord. If this supply cable is damaged, it must be replaced by the manufacturer,

its after sales service or a similarly qualified technician to avoid any danger.

ADVICE

•

Leave the inlets free to allow in/out air circulation.

SECURITY

Cutting can be dangerous and lead to serious or even fatal injuries. Protect yourself and protect the

others.

Respect the following warnings:

Arc rays :

Protect yourself thanks to a welding helmet in compliance with EN175 equiped with filters in

compliance with EN 169 or EN 379. Inform and protect by the same means any people in the

welding environment.

Rain, steam,

The working environment must be clean (degree of pollution ≤ 3) and protected

humidity :

against rain. Put the appliance on an even place and at least at one meter from the parts to

be cut. Do not use them under rain or snow.

Electric shocks :

This appliance may only be use with a 230V monophase supply and must be earthed.

Moving :

Do not underestimate the weight of the apparatus. Do not carry it over people or things. Do

not drop it. Do not set it brutally

Burns :

Wear protective or fire-proof clothing (overalls, jeans).

Use some welder gloves and a fire-proof apron.

Protect the others by installing non flammable protection wall, or prevent the

others from looking at the arc and make them keep a sufficient distance

Fire risks:

Suppress all flammable products from the working area. Do not work near flammable gas.

Smokes:

Do not inhale gas or welding smokes. If indoors ventilate the area well and/or use local

extraction ventilation equipment to remove fumes and gases.

Extraprecautions:

Any cutting operation: