7/27

Fire risks :

Suppress all flammable products from the working area. Do not works near flammable gas.

Smokes :

Do not inhale gas or welding smokes. If indoors ventilate the area well and/or use local

extraction ventilation equipment to remove fumes and gases.

Extraprecautions :

Any welding operation :

- in environments with increased risk of electric shock,

- in confined spaces,

- in the presence of flammable or explosive materials

must be evaluated in advance by an “Expert supervisor” and must always be carried out in

the presence of other people trained to intervene in case of emergency.

Technical protection measures MUST BE taken as described in the TECHNICAL

SPECIFICATION "IEC 62081".

Welding in raised positions is forbidden unless safety platforms are used.

The persons carrying pacemaker have to consult a doctor before using these machines

Do not use the unit to thaw tubing.

In TIG welding, manipulate the gas bottle carefully. Indeed, there are risks if the bottle or the bottle

valve are damaged.

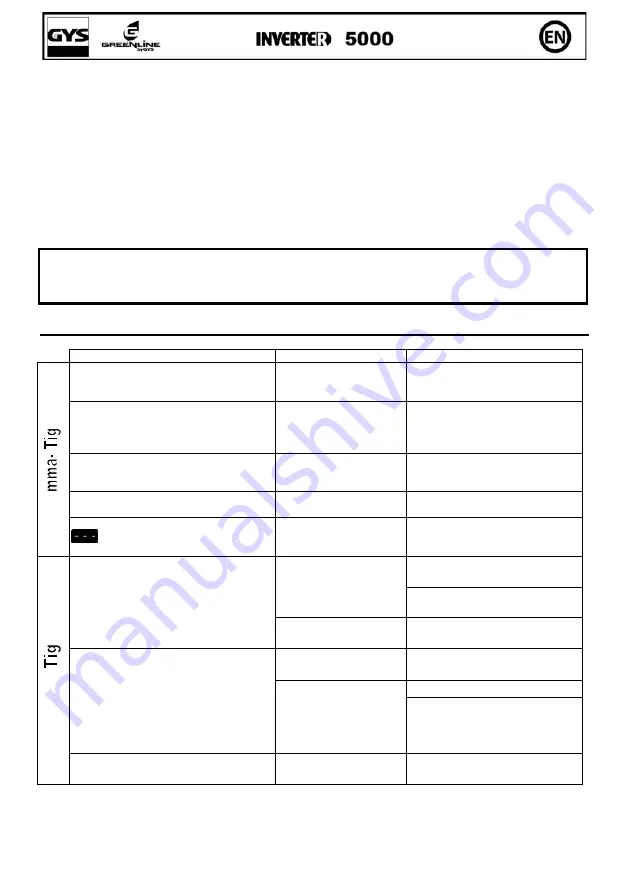

TROUBLESHOOTING

Anomalies

Causes

Remedies

The device does not deliver any current

and the yellow indicator lamp of thermal

defect

lights up.

The welder thermal

protection has turned on.

Wait for the end of the cooling

time, around 2 minutes. The

indicator lamp

turns off.

The display is on but the device does not

deliver any current.

The cable of the earth

clamp or electrode holder

is not connected to the

welder.

Check the connections.

If, when the unit is on and you put your

hand on the welding unit’s body, you feel

tingling sensation.

The welding unit is not

correctly connected to

the earth.

Check the plug and the earth of

your electrical network.

Your unit does not weld correctly.

Polarity error.

Check the polarity advised on the

electrode packaging.

When starting up, the display indicates

during one second and turns off.

The voltage is not

included in the range

230V +/- 15%

Have the electrical installation

checked.

Instable arc

Default coming from the

tungsten electrode

Use a tungsten electrode with the

adequate size

Use a well prepared tungsten

electrode

Too important gas flow

rate

Reduce gas flow rate

The tungsten electrode gets oxidised and

tern at the end of welding.

Welding zone

Protect welding zone against air

flows

Default coming from

post-gas or the gas has

been stopped

prematurely.

Increase post-gas duration

Check and tighten all gas

connections. Wait until the

electrode cools down before

stopping the gas.

The electrode melts

Polarity error

Check that the earth clamp is really

connected to +