11

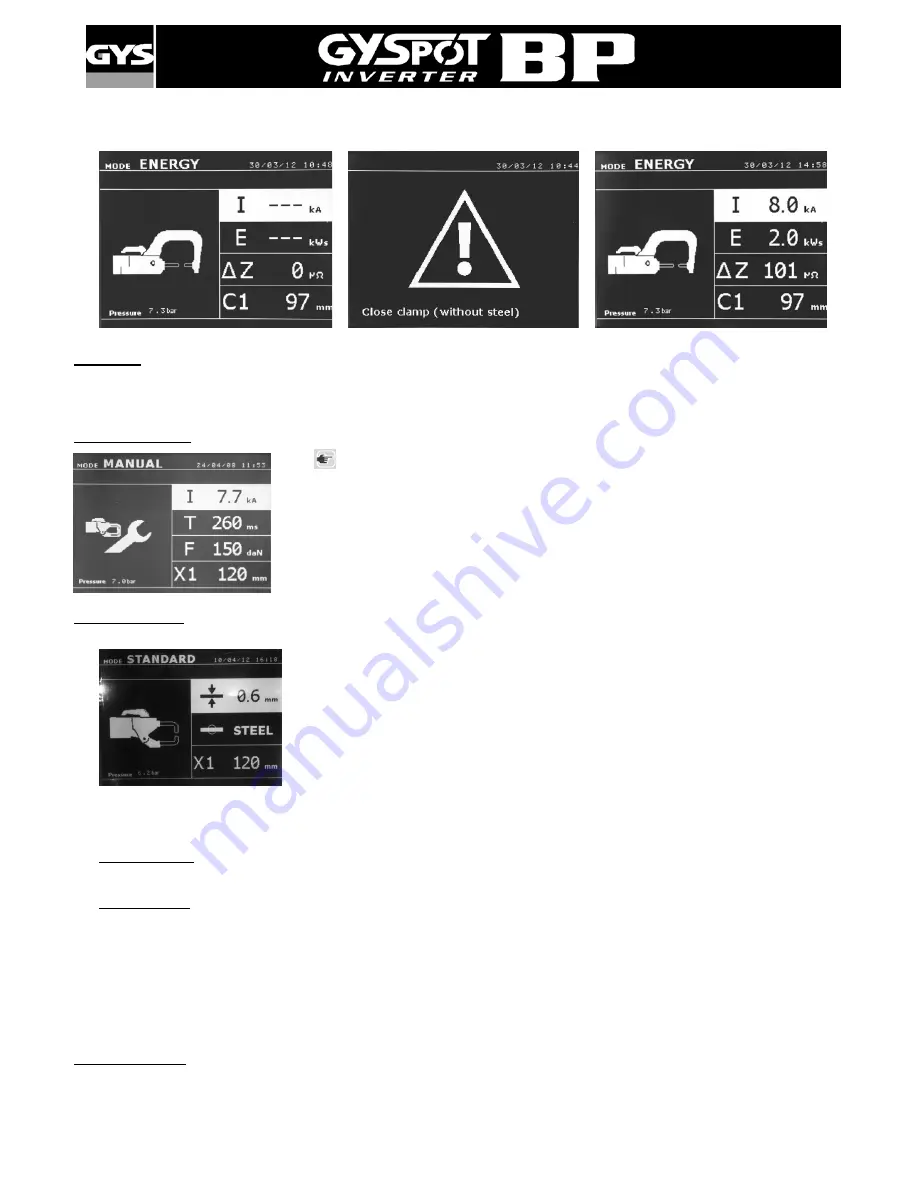

The user can then change the welding current, the energy, and the impedance. The machine will weld during the time

necessary to reach the requested energy. If the welding is too long, the machine will display an error message « Timeout

(ms) »

X clamp

♦

Line up the electrodes so they face each other, then set and tighten the clamp arms (couple: 15 Nm).

♦

Enter « clamp adjustment » mode to check the alignment of the electrodes.

♦

The force is calculated by the machine according to the setting of the force or of the sheet thickness.

Clamp adjustment

The

key is used change from one tool to the next, as well as to enter the clamp

adjustment mode. The clamp adjustment mode allows the user to close the clamp and

apply the programmed force on the electrodes without any current flowing. This mode is

used to adjust the arms. The clamp will remain closed as long as the button remains

pressed; this allows the user to check the alignment of the electrodes and positioning of

the caps.

STANDARD mode

This is the default mode when the machine starts. Quick and easy spot welding by selection of:

♦

Type of tool used

♦

Sheet thickness:

0.6, 0.8, 1.0, 1.2, 1.5, 1.8, 2.0, 2.5, 3.0.

♦

Type of steel (coated steel, HTS steel, UHTS steel, BORON steel), and the arm to be

used.

♦

The up and down keys (key definition diagram, (3) ) scroll through the parameters to

modify (sheet thickness, type of steel, arm used). The + and – keys allow modification of

each parameter.

Button A on the clamp remotely adjusts the thickness of the sheets to be welded.

Button B on the clamp creates a welding spot using the selected parameters.

Pressing button close / weld allows the user to make a welding spot using the selected parameters.

Before the weld: If the input air pressure is too low to reach the required electrode force, a warning will sound, and the

machine will display the error message “Pressure too low”. Pressing the button for a second time will force the execution of

the welding spot with the available air pressure.

After the weld: If the welding current measured during the spot is 6% less than the setting, the machine will display the

error message “Current too low” - the welding spot should be checked.

A message will be displayed at the end of every welding spot, showing the measured welding current and electrode force.

This message is displayed on the screen until a key on the control panel is pressed, or until a new welding spot is

performed, by pressing the B button on the clamp.

Multi-sheet mode

This mode allows the user specify the thickness and type of each sheet in an assembly of 2 or 3 sheets.

The first piece (Thickness of the metal sheet 1) is selected. The up and down button allows the selection of the parameters

for each sheet. When the parameters for a sheet are highlighted, the sheet thickness and type of steel can be adjusted

using the + and – keys.