12

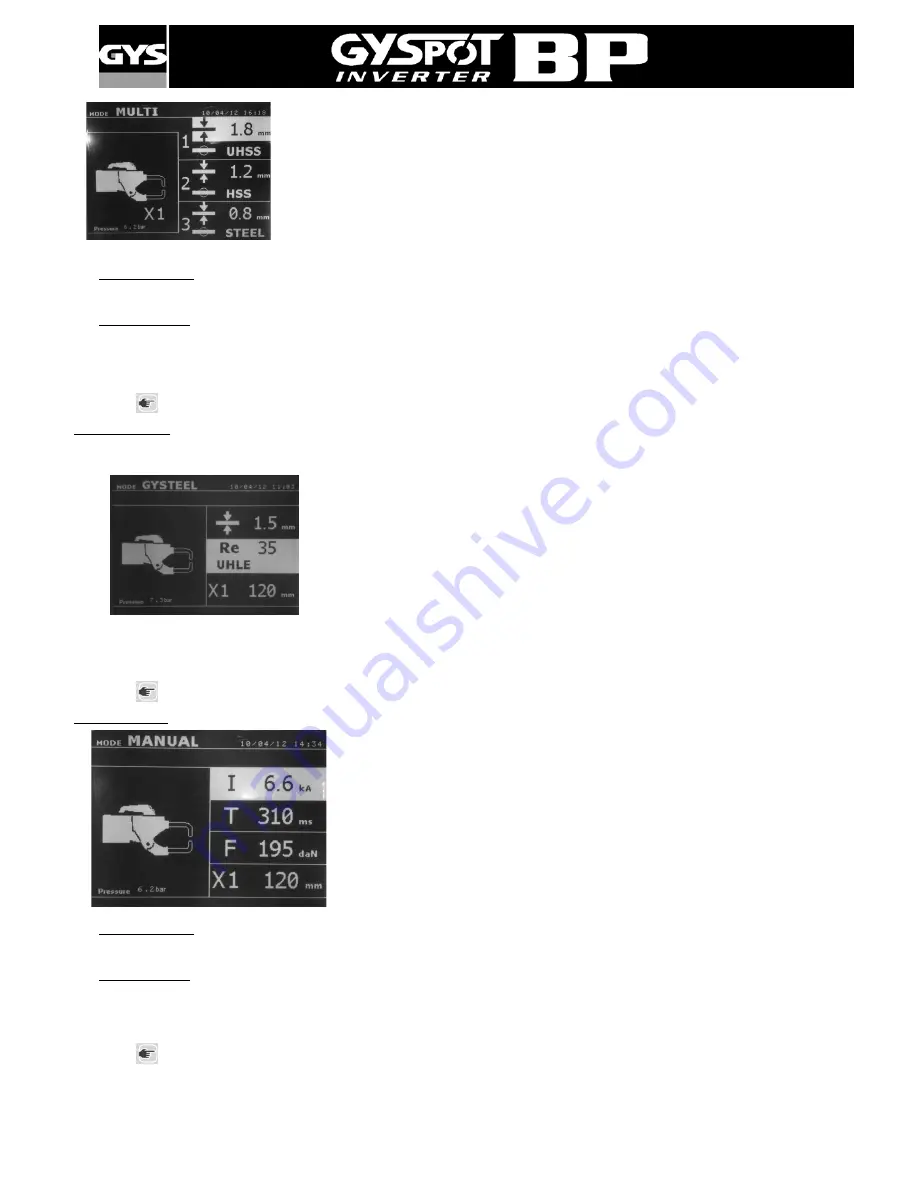

The parameters to set in that mode are:

♦

Thickness of steel sheet 1: 0.6, 0.8, 1.0, 1.2, 1.5, 1.8, 2.0, 2.5, 3.0

♦

Type of the steel 1: coated steel, HTS steel, UHTS steel, BORON steel.

♦

Thickness of the steel sheet 2: the same as the metal sheet 1.

♦

Type of the steel 2: the same as the metal sheet 1.

♦

Thickness of the steel sheet 3: deactivate the mode by default (« --- ») or the same as

the metal sheet 1.

♦

Type of the steel 3 : deactivate the mode by default (« --- ») or the same as the metal

sheet 1.

♦

To activate the metal sheet 3 press the up and down keys to highlight the metal sheet

3.

Before the weld: If the input air pressure is too low to reach the required electrode force, a warning will sound, and the

machine will display the error message “Pressure too low”. Pressing the button for a second time will force the execution of

the welding spot with the available air pressure.

After the weld: If the welding current measured during the spot is 6% less than the setting, the machine will display the

error message “Current too low” - the welding spot should be checked.

A message will be displayed at the end of every welding spot, showing the measured welding current and electrode force.

This message is displayed on the screen until a key on the control panel is pressed, or until a new welding spot is

performed, by pressing the B button on the clamp.

Press

for 2 seconds to revert back to standard mode.

GYSTEEL mode

The auto mode is optional and is configurable in the setup menu that is activated by pressing the mode key for 2 seconds

(auto mode on / off).

The auto mode is identical to normal mode except that the user enters the yield

strength of steel. The Ys may be found using a durometer such as Gysteel Vision

Re: 1-10 corresponds to mild steels.

Re: 11-18 corresponds to HSS/THSS steels.

Re: 19-35 corresponds to UHSS steels.

Re: 36-99 corresponds to boron steel.

♦

Sheet thickness: 0.6, 0.8, 1.0, 1.2, 1.5, 1.8, 2.0, 2.5, 3.0.

♦

Type of arm used.

The up and down button (

or

) scrolls through the parameters to modify (sheet thickness, Yield strength, arm used).

The + and – keys allow modification of each parameter.

Button A on the clamp allows the user change the thickness of the sheets to be welded remotely.

Button B on the clamp allows the user to spot weld with the selected parameters.

Press

for 2 seconds to revert back to standard mode

MANUAL mode

This mode allows the user to manually select the welding parameters, for

example when following instructions from a manufacturer . The settings

proposed by default in the manual mode correspond to the settings automatically

selected by the standard mode (thickness and type of sheet, electrode force,

arm).

The parameters can be adjusted using the + and – keys. The up and down keys

scroll from one parameter to the next:

♦

Welding current (from 2000A to maximum current, steps of 100 A), in kA.

♦

Welding time (100 to 850 ms, steps of 10 ms)

♦

Electrode force (100 to 550 daN, steps of 5 daN)

♦

Arm used on the clamp (number and length)

Before the weld: If the input air pressure is too low to reach the required electrode force, a warning will sound, and the

machine will display the error message “Pressure too low”. Pressing the button for a second time will force the execution of

the welding spot with the available air pressure.

After the weld: If the welding current measured during the spot is 6% less than the setting, the machine will display the

error message “Current too low” - the welding spot should be checked.

A message will be displayed at the end of every welding spot, showing the measured welding current and electrode force.

This message is displayed on the screen until a key on the control panel is pressed, or until a new welding spot is

performed, by pressing the B button on the clamp.

Press

for 2 seconds to revert back to standard mode.