22

5- USE AND MAINTENANCE PRECAUTIONS

User training

Any operator of this machine should receive training adapted to its use in order to gain maximum performance from the

unit (e.g.: car body repair training).

Adjust the balancer’s spring tension

Adjust the balancer’s spring tension with the Allen key equipped. Do not leave the clamp hanging for a long time on the

balancer, as it would induce early wear out of this part. Do not let the clamp fall down repeatedly without holding it, as it

could damage the balancer.

Preparation of the work-piece:

Grind and clean the work-piece thoroughly before welding.

If protection is being used, ensure that the parts are conducting by testing a sample.

Single sided gun welding

Before repairing a car, check that the car manufacturer authorizes that welding process.

Cooling liquid level and efficiency

The cooling liquid level is important to ensure the unit functions correctly. The liquid level should always be between the

minimum and maximum levels indicated on the tank. Check the level and efficiency of the cooling liquid regularly, replace if

needed. It is recommended replacing the cooling liquid every 2 years.

Cleaning the pneumatic filter

Ensure the dehumidifier filter located at the back of the machine is cleaned regularly.

Generator maintenance

The maintenance and repair of the generator should only be carried out by a GYS technician. Any repair/maintenance made

to the generator by unauthorized personnel will invalidate the machine's warranty - GYS will not take responsibility for any

incident or accident under these circumstances.

Cleaning / replacement of welding tools and other items

All welding tools are consumable and will deteriorate during use.

To extend the lifespan and efficiency of the tools, ensure that they are inspected and cleaned regularly.

When using with the Pneumatic Clamp, check that the condition of the electrodes/CAPS (flats, rounded or beveled) is good.

If the condition is poor, clean with fine grain sandpaper, or replace (see reference on the machine).

When using with the gun, check the condition of the tools: star, single-point electrode, carbon electrode. Clean, or replace if

necessary.

Ensure the pneumatic filter is clean to prevent the machine overheating.

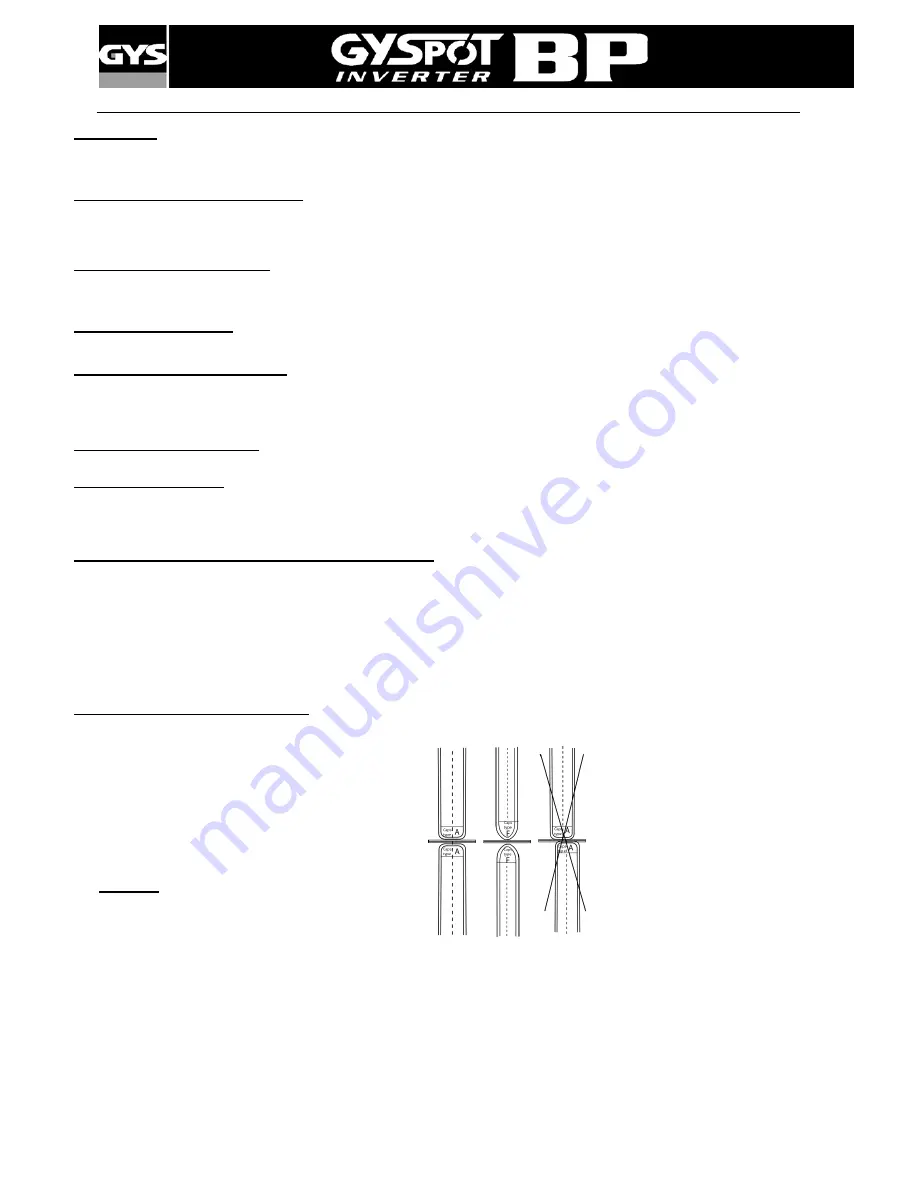

Replacement of the caps/electrodes:

♦

To ensure an efficient welding point, you need to replace the caps every 200 spots - remove the caps using the spanner.

(Ref. 050846)

♦

Use grease (ref: 050440) when replacing caps

♦

Caps type A (ref: 049987)

♦

Caps type F (ref: 049970)

♦

Caps beveled (ref: 049994)

Caution:

The caps must be perfectly aligned. To

check the electrode line, see change of arms on

pages 18 and 19.